Feeding and reclaiming manipulator

A reclaiming manipulator and free technology, applied in the field of manipulators, can solve the problems of inaccurate position, sticking and offset of circuit board punching, and achieve the effect of avoiding gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

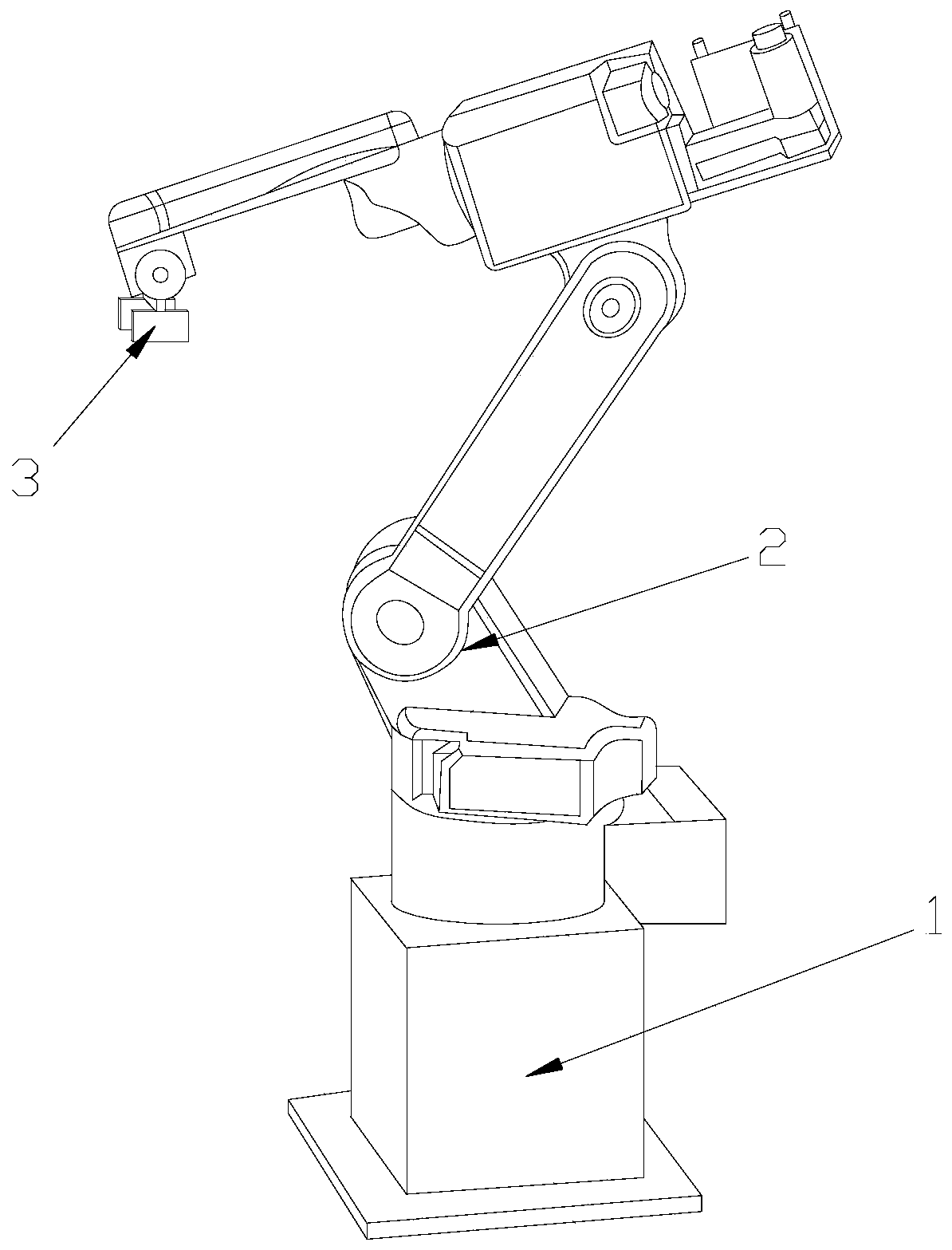

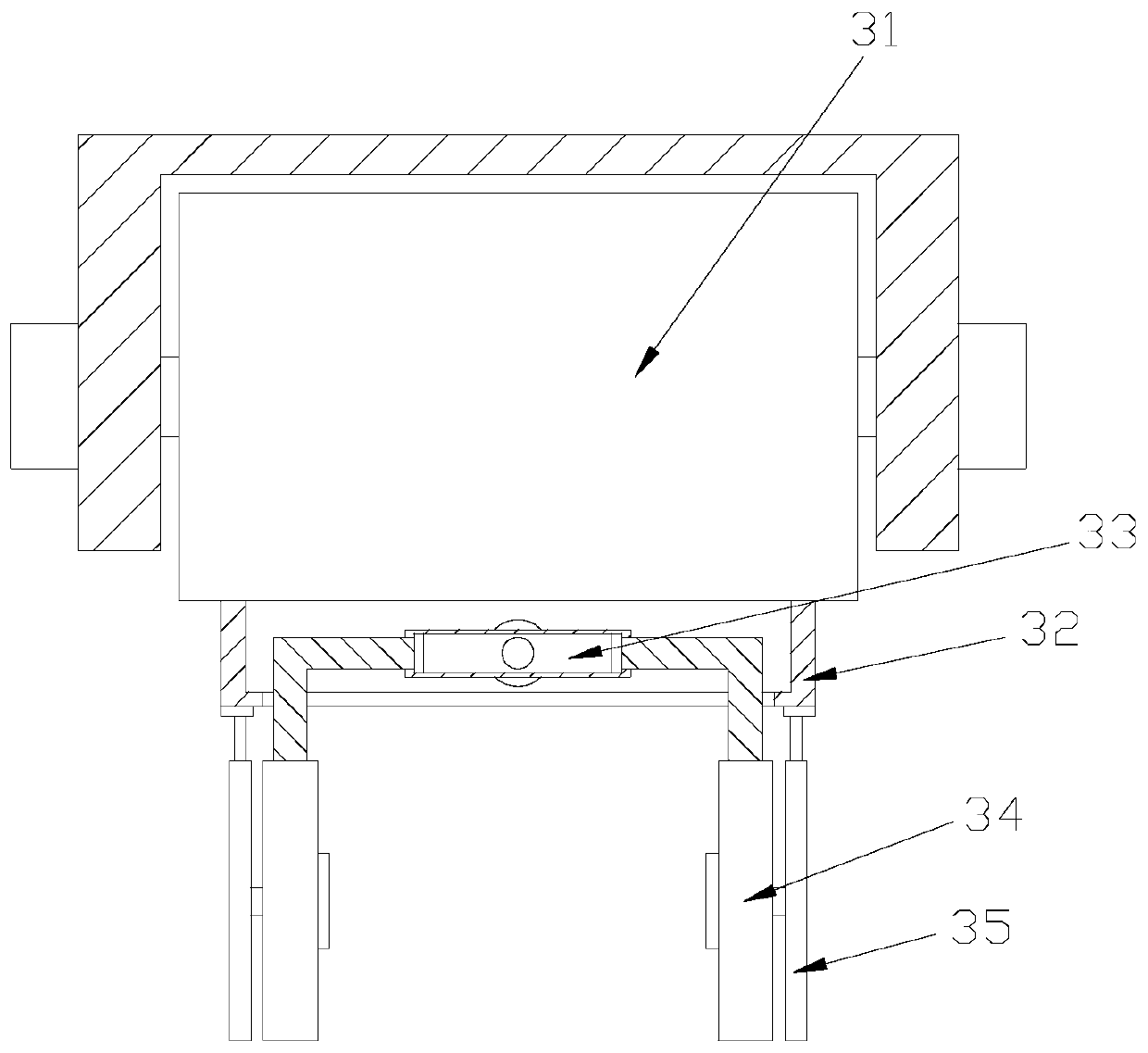

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiment of the present invention is as follows: its structure comprises support base 1, free arm 2, clamp 3, and the upper end of described support base 1 is equipped with free arm 2, and described clamp 3 is installed on the upper end of free arm 2, described The fixture 3 includes a roller 31, a support block 32, a piston 33, a clamping block 34, and a push block 35. The bottom of the roller 31 is embedded with a support block 32, and the piston 33 is installed in the middle of the support block 32. There are two clamping blocks 34, which are respectively connected to the two ends of the piston 33; Cooperate.

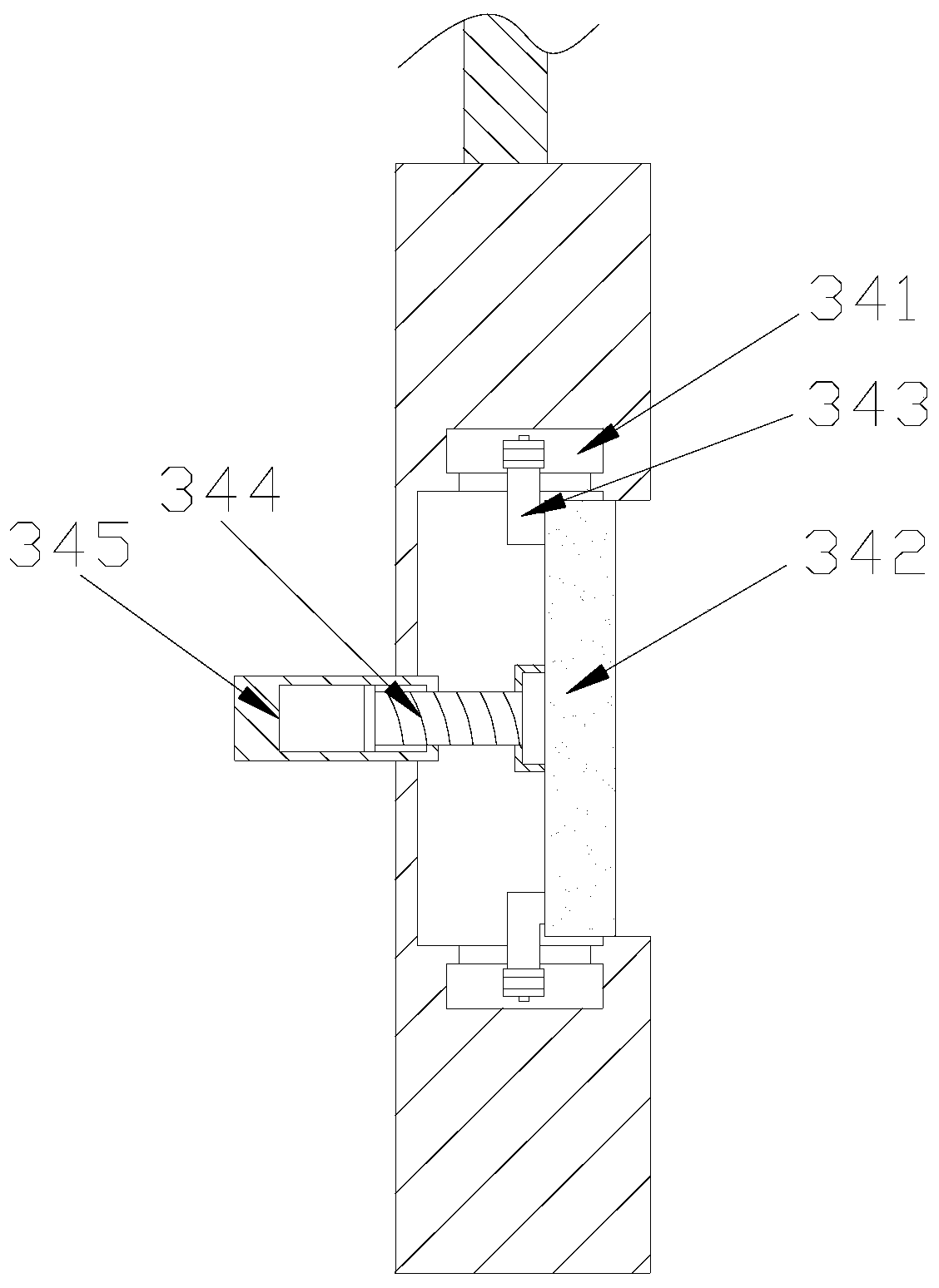

[0027] The clamping block 34 includes a rolling groove 341, a scraping block 342, a rolling shaft 343, a threaded rod 344, and a threaded card body 345. On the side, the scraping block 342 is located in the middle of the two rolling grooves 341, and the rolling shaft 343 is provided with two, whi...

Embodiment 2

[0031] Example 2: Please refer to Figure 6-Figure 8 The specific embodiment of the present invention is as follows: the scraper rod a34 includes a rod body b1, a connecting hole b2, and a rubber block b3, the front end of the rod body b1 is provided with a connecting hole b2, and the connecting hole b2 runs through the rod body b1. A rubber block b3 is attached to the bottom of the rod body b1 , and the rod body b1 is arc-shaped, which facilitates pushing the scraped debris to the end of the rod body b1 so that the debris falls from the clamping block 34 .

[0032] The rubber block b3 includes a rubber body b31, a groove b32, and a guide b33. The bottom end of the rubber body b31 is provided with a groove b32, and the guide b33 is installed at the end of the rubber body b31. The groove b32 It is stepped, so that debris moving towards the outer end of the rubber body b31 will be caught by the groove b32, and the debris will not move back.

[0033]The guiding device b33 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com