Numerical control longitudinal cutting device for non-interference cutter taking and use

A slitting device, non-interference technology, applied in packaging and other directions, can solve the problems of operation interference, complicated operation, and limited cutting products, and achieve the effect of high degree of automation and simplified operation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

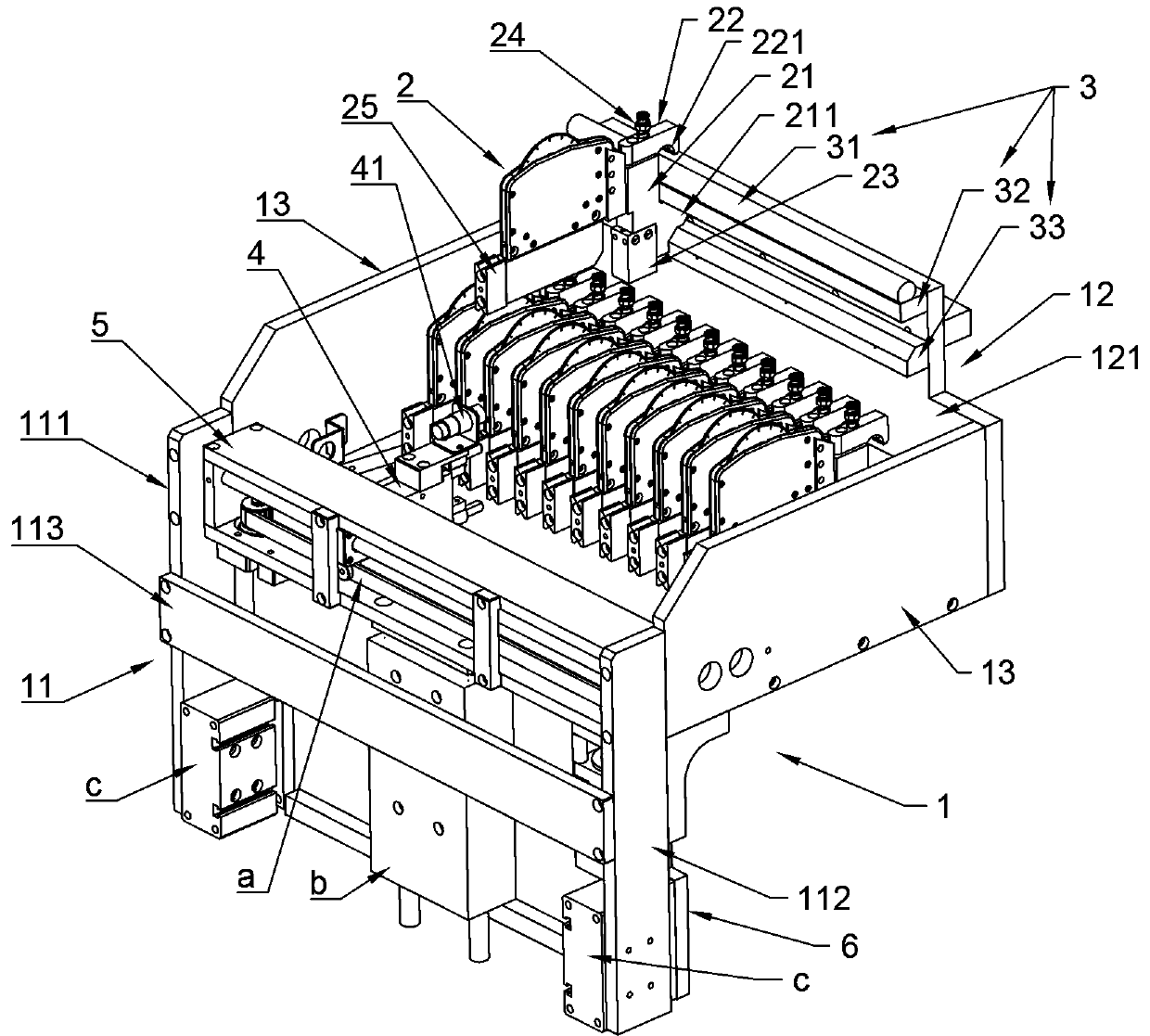

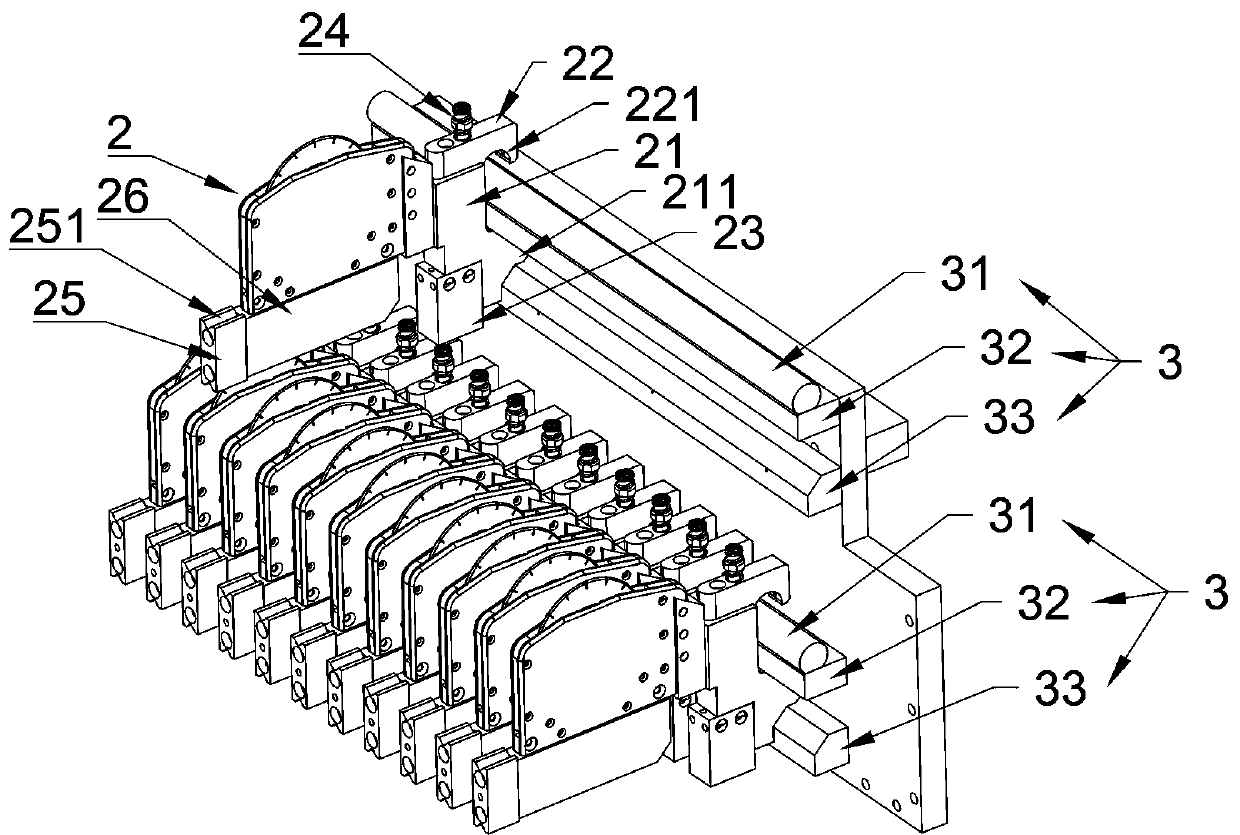

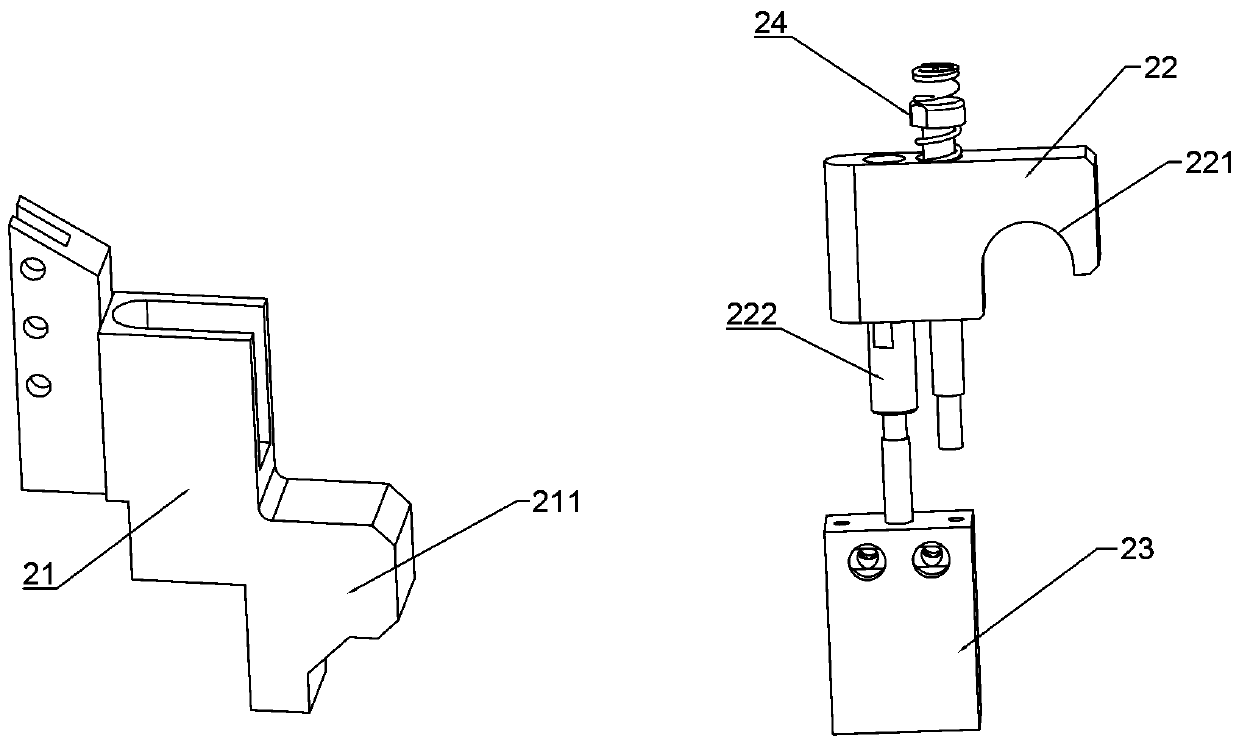

[0029] See figure 1, a CNC slitting device for picking and using knives without interference, including a frame 1, a number of floating hobs 2, a knife picking manipulator 4, a moving mechanism and two knife rests 3 (the two knife rests 3 are conventional and meet the requirements design, one as a cutting tool rest, and one as a parking tool rest), frame 1 includes a front frame 11 and a rear frame 12. Knife fetching manipulator 4 is connected on the moving mechanism, and moving mechanism is connected on the front frame 11 (moving mechanism also can be arranged separately, such as being installed on another mounting frame beside frame 1); Tool rest 3 is connected on rear frame 12, the floating hob 2 is connected with a hook mechanism and is hung on the frame 12 through the hook mechanism.

[0030] This embodiment figure 1 , figure 2 , Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com