Device for automatically cutting glass of any size

An automatic cutting and sizing technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of accidental injury of discarded glass, broken edges of glass, finding fixing devices and inaccurate size, etc., to avoid accidental injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

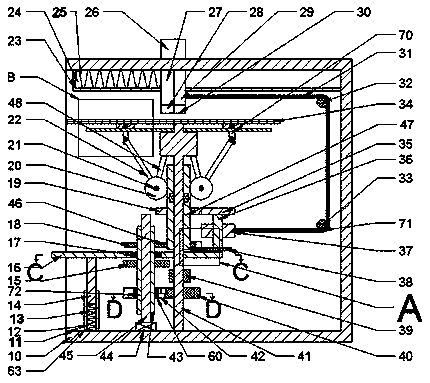

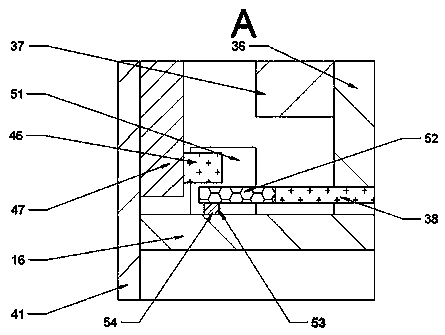

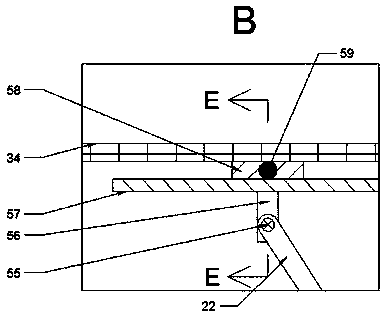

[0017] Combine below Figure 1-5 The present invention will be described in detail, in which, for the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0018] Attached Figure 1-5 The described device for automatically cutting glass of any size includes a placement block 10, in which a placement cavity 11 with a leftward opening is provided, and a supporting mechanism 70 is provided in the placement cavity 11, the supporting mechanism 70 includes a first rotating shaft 41 rotatably connected with the inner wall of the lower side of the placement cavity 11, the first rotating shaft 41 is provided with a worm 47 rotatably connected with the first rotating shaft 41, and the worm 47 is bilaterally symmetrical Two worm wheels 20 connected in rotation are provided. The worm wheel 20 is provided with a second rotating shaft 21 connected in rotation. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com