Unit curtain wall easy to assemble and disassemble, construction tool and construction method

A unit curtain wall, easy disassembly and assembly technology, applied in the direction of walls, building maintenance, building components, etc., can solve the problems of complex structure of disassembly and assembly tools, large size of disassembly and assembly tools, troublesome use, etc., to achieve convenient disassembly and assembly operation and versatility Strong, convenient storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

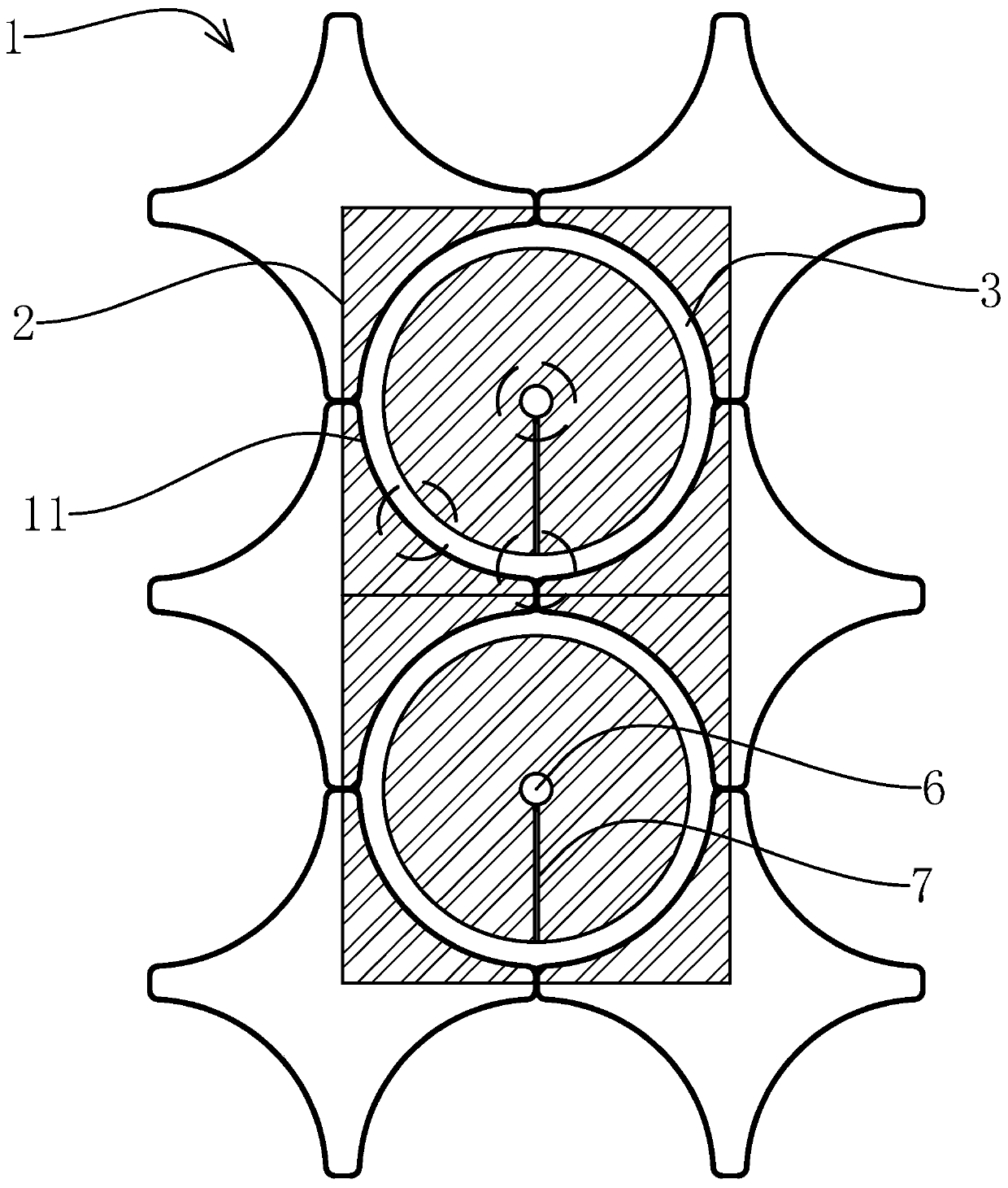

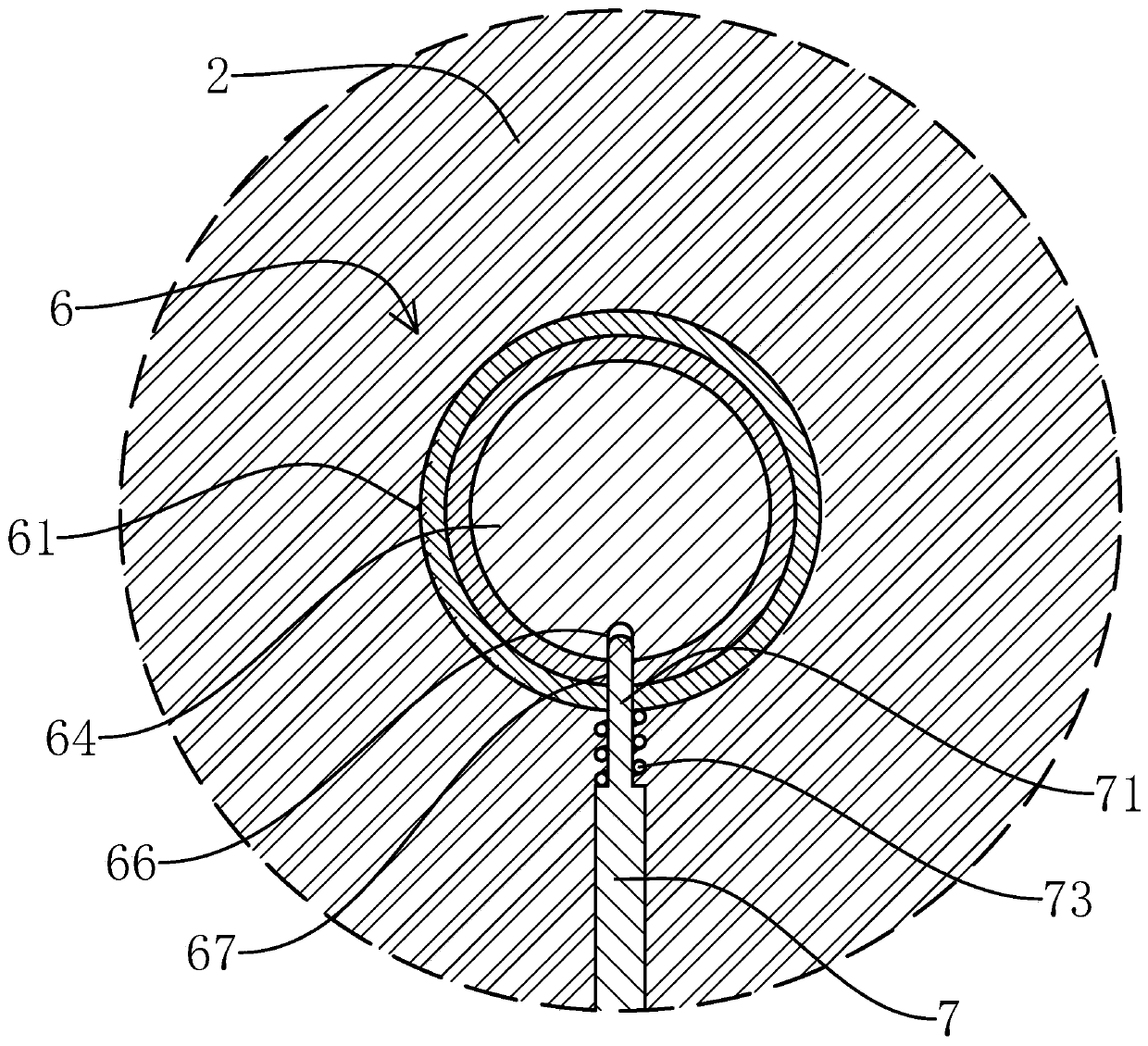

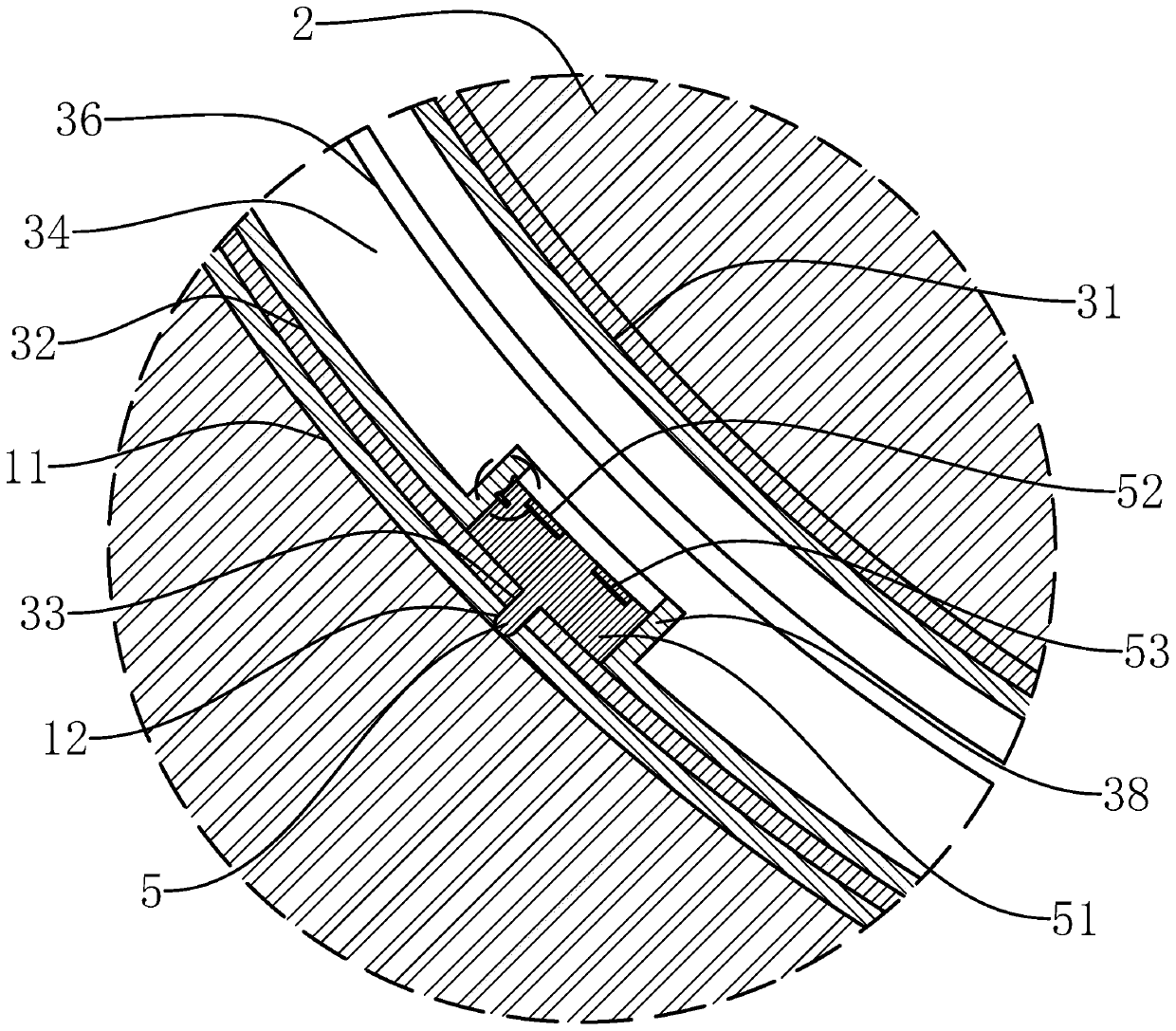

[0052] Such as Figure 1-10 As shown, an easily disassembled unit curtain wall of the present invention includes a connecting frame 11 of an annular sleeve structure fixed on the wall surface, and the inner wall of the connecting frame 11 is provided with several locking grooves arranged radially along the connecting frame 11 in the depth direction. 12. It also includes a tempered glass panel 2 with a rectangular plate structure, and the inner side of the panel 2 is respectively provided with a connecting seat 3, a fixing seat 6 and an adjusting rod 7;

[0053] The connecting seat 3 is an annular hollow tubular structure, and is surrounded by an inner connecting sleeve 31 and an outer connecting sleeve 32 of an annular sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com