Assembly type equal-length vertical web truss slope roof beam system structure

A truss girder and prefabricated technology, applied in truss structure, truss girder, joist and other directions, can solve the problems of inability to waste space, large waste of structural space, difficult construction, etc., and achieve the effect of convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

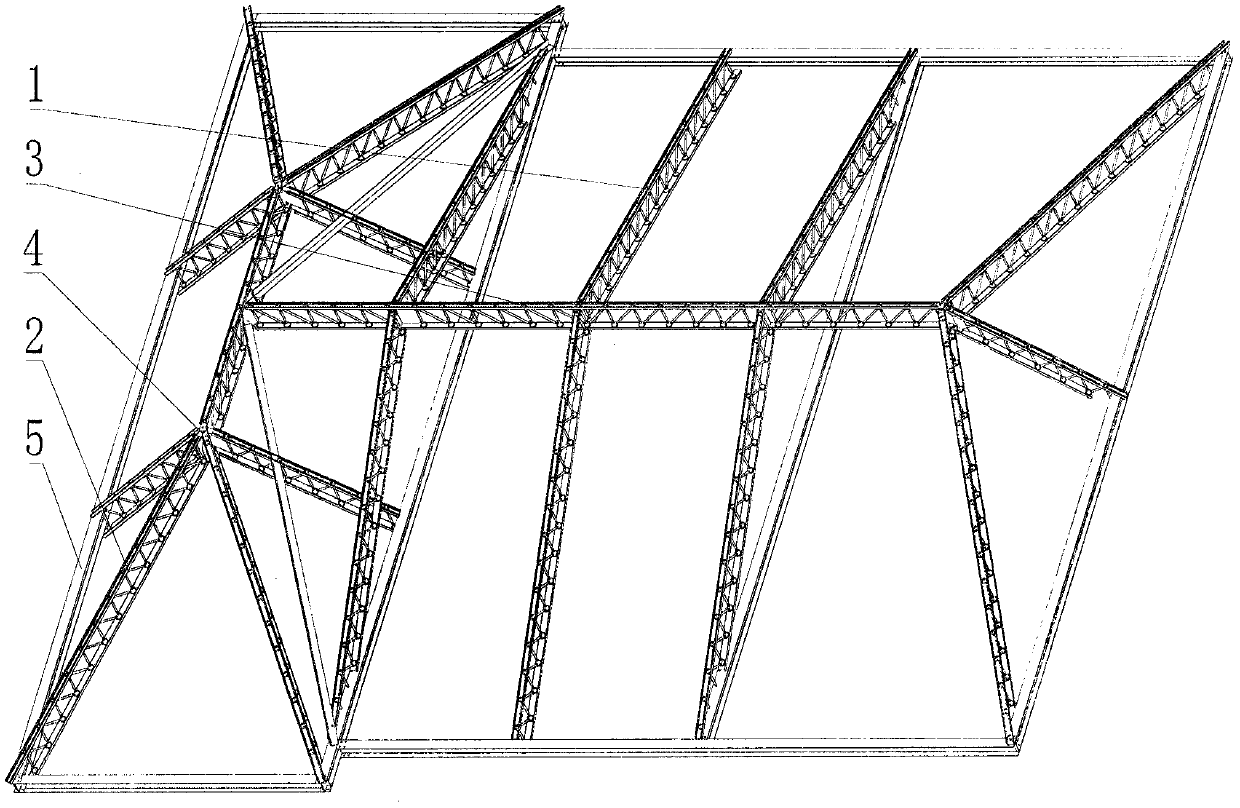

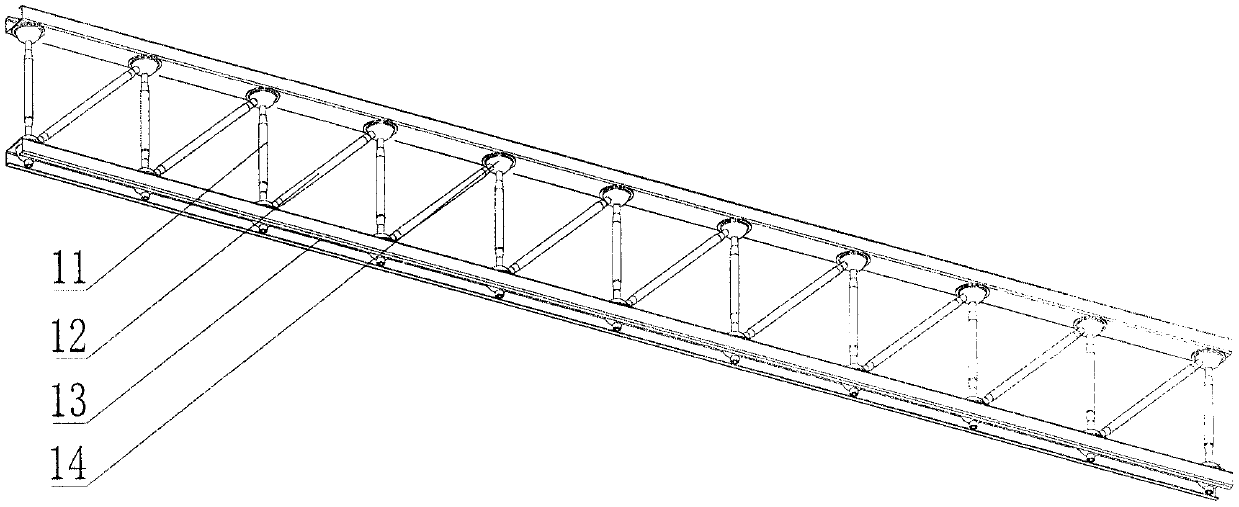

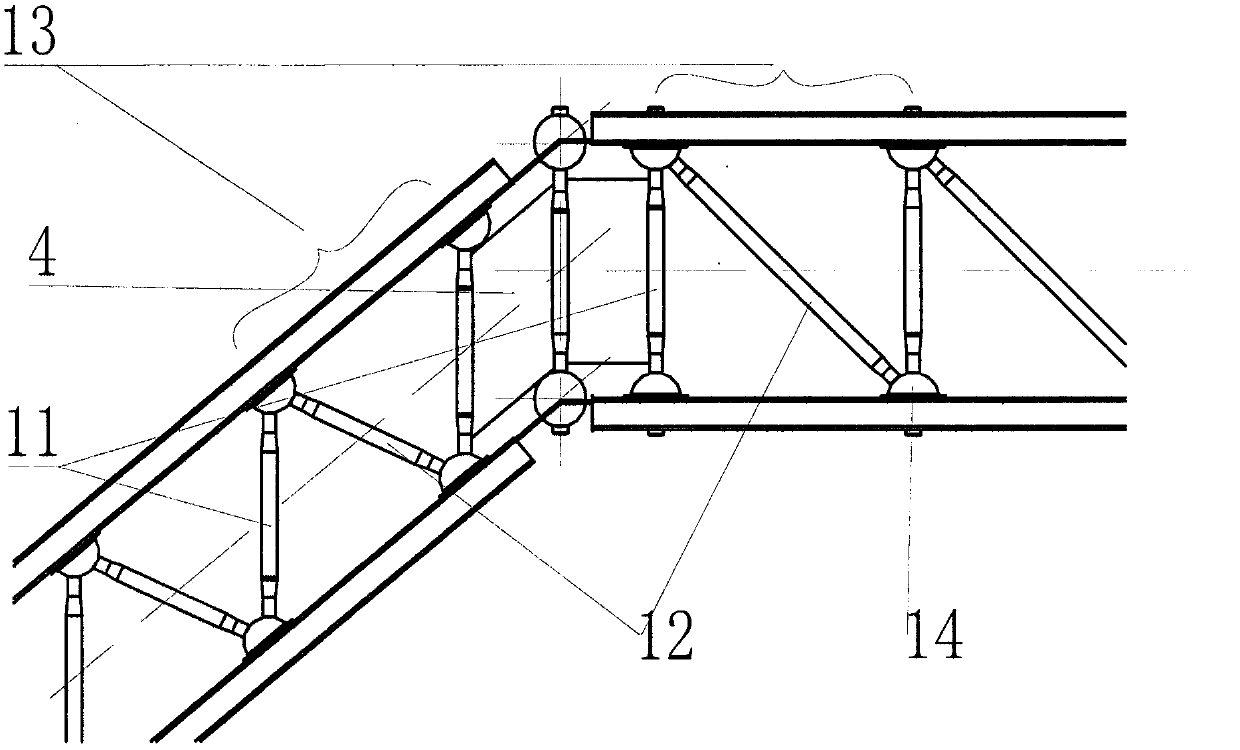

[0022] see Figure 1 to Figure 6 As shown, the assembled equal-length vertical web bar truss sloping roof beam system structure of the present invention includes truss beams 1 on each slope, oblique truss beams 2 between two adjacent slopes, and ridge trusses intersecting at the top of two opposite slopes. Beam 3, truss beam node 4 where trusses intersect and main frame 5; it is characterized in that each slope truss beam 1, oblique truss beam 2 and roof truss beam 3 are plane truss structures, and the plane truss structures include vertical webs Rods 11, oblique webs 12, chords 13, and ball joints 14 placed above and below the chords 13 and connecting the vertical webs 11 and oblique webs 12, wherein each of the slope truss beams 1, diagonal The vertical web bars 11 of the truss beam 2 and the roof truss beam 3 are all perpendicular to the horizontal plane, wherein the vertical web bars 11 of the slope truss beam 1, the oblique truss beam 2 and the roof truss beam 3 are all o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com