Construction site foundation pit protective guard with good warning effect

A kind of protective fence, good technology, applied in the direction of fence, electrostatic effect separation, infrastructure engineering, etc., can solve the problems of weakening warning effect, weak light, general warning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

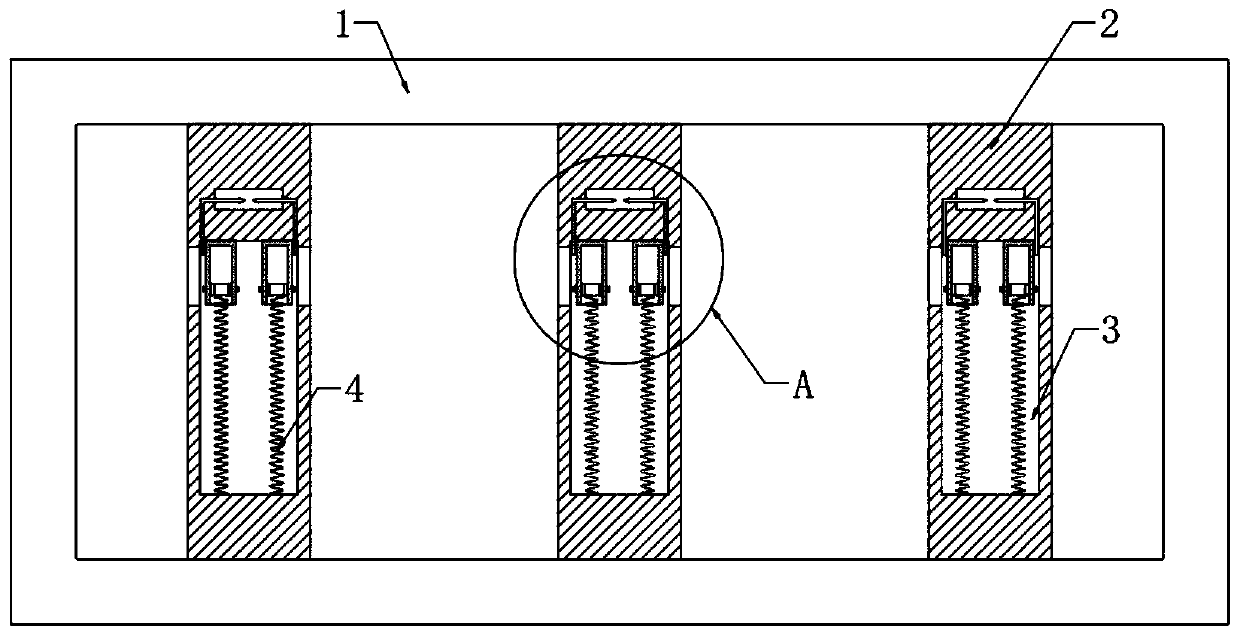

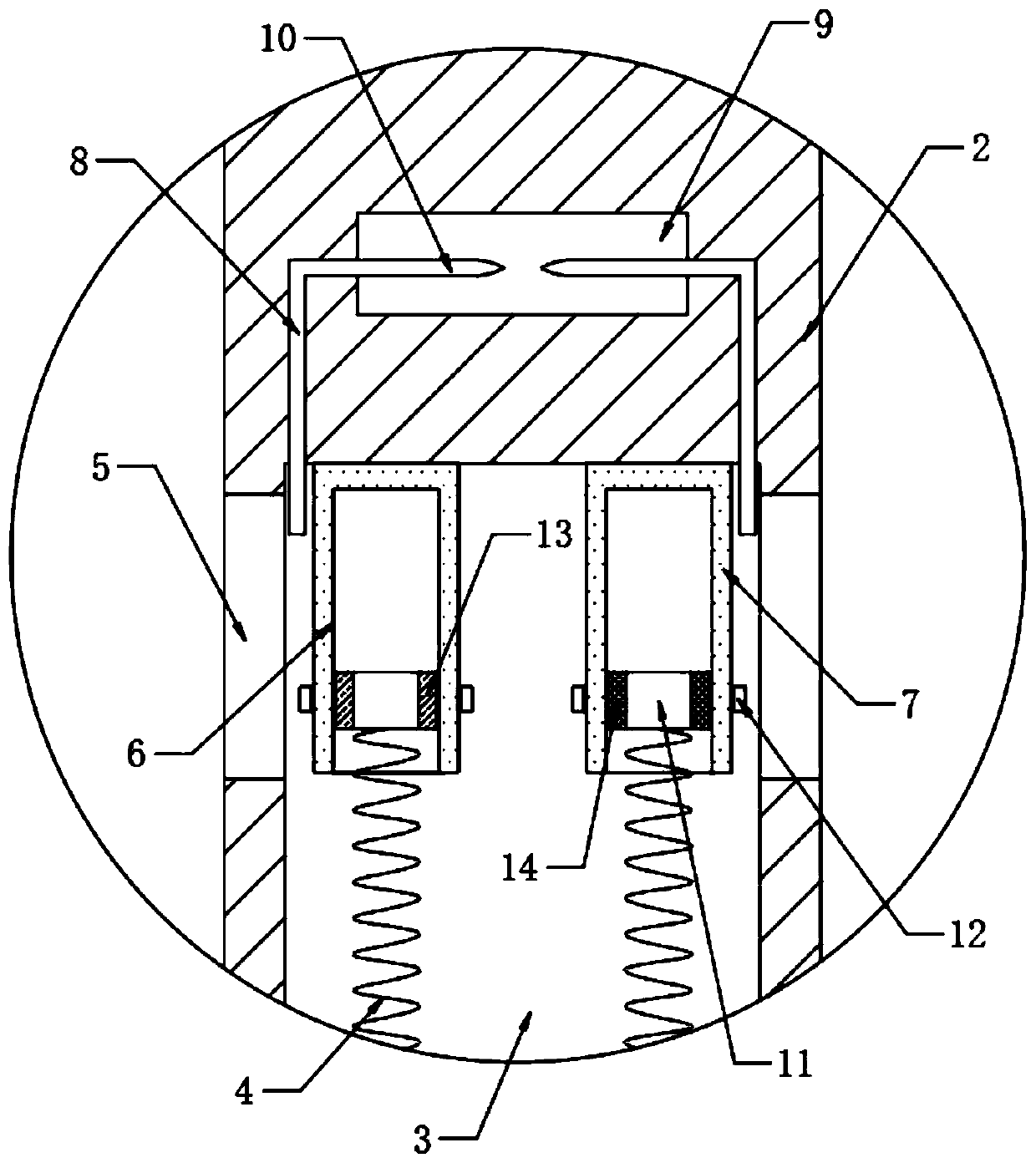

[0020] refer to Figure 1-2 , a construction site foundation pit protective fence with good warning effect, comprising a frame body 1, a plurality of railings 2 welded inside the frame body 1, bar-shaped grooves 3 are opened on the side walls of the railings 2, and the inner bottoms of the bar-shaped grooves 3 are fixedly connected There are two springs 4, and the inner top of the strip groove 3 is fixedly connected with a glass sleeve 6 and a rubber sleeve 7. When the spring 4 is manufactured, the natural frequency of the spring 4 needs to be set to be the same as the natural frequency of the construction machinery such as excavators, bulldozers and other equipment engines for foundation pit construction on the construction site.

[0021] Both the glass sleeve 6 and the rubber sleeve 7 are slidably connected with an iron slider 11, and the outer walls of the glass sleeve 6 and the rubber sleeve 7 are slidably connected with a magnetic wiper ring 12, wherein the magnetic scrap...

Embodiment 2

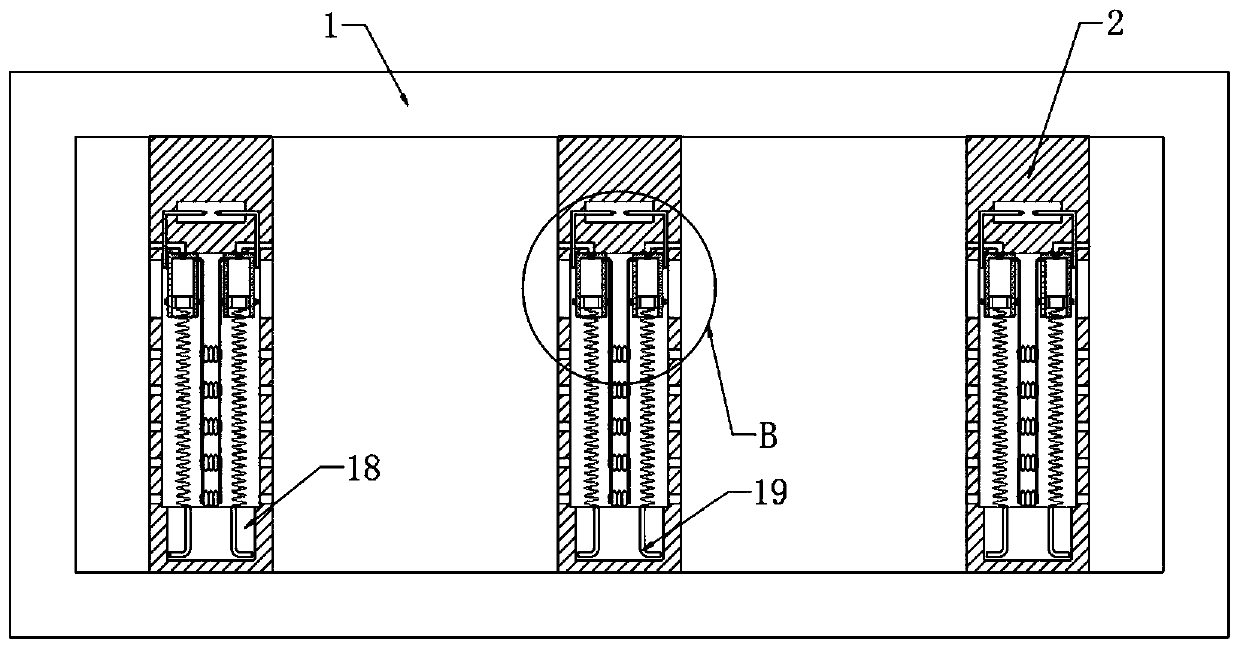

[0027] refer to Figure 3-4 , different from Embodiment 1, the side wall of the railing 2 is provided with a plurality of spray holes 16, and the inner wall of the strip groove 3 is fixedly connected with a plurality of telescopic airbags 15, and the air outlet end of the telescopic airbag 15 faces the nozzle holes 16, A pressure relief valve is installed in the air outlet of the telescopic airbag 15, and the plurality of telescopic airbags 15 are connected to each other. The side wall of the railing 2 is provided with two air inlets 17 respectively connected with the glass sleeve 6 and the rubber sleeve 7. Both ends of the airbag 15 are respectively provided with an air guide tube 20 communicating with the glass sleeve 6 and the rubber sleeve 7 , a first one-way valve is installed in the air inlet 17 , and a second one-way valve is installed in the air guide tube 20 . The first one-way valve only allows air to flow into the glass sleeve 6 or the rubber sleeve 7 from the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com