Intelligent visual detection method and system applied to injection molding part defective product detection

A technology of intelligent vision and detection system, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of poor robustness and generalization ability, and achieve the effect of high robustness and generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

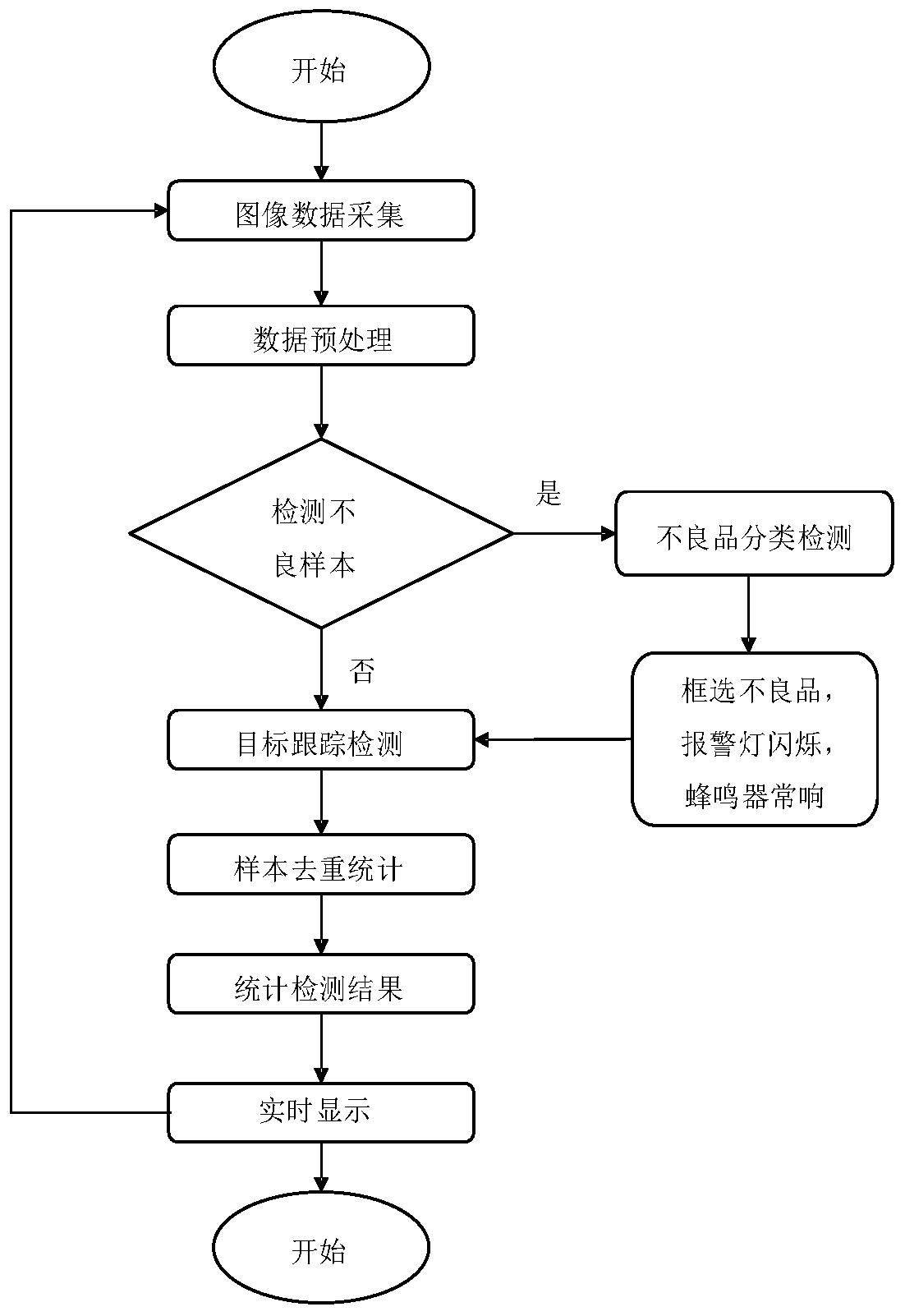

[0043] refer to figure 1 , image 3 , Figure 4 and Figure 5 , the present disclosure provides an intelligent visual detection method applied to the detection of defective injection molded parts, comprising the following steps:

[0044] S101. Obtain the video stream data of the sample to be detected;

[0045] S102. Decompose the video stream data into single frame image data;

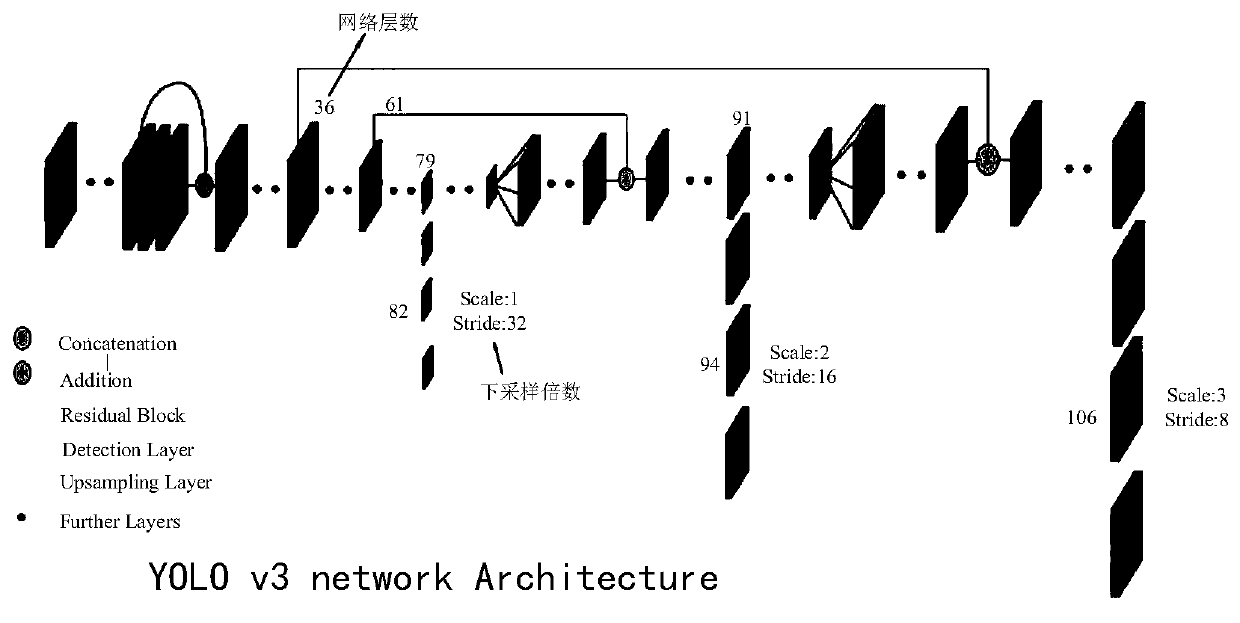

[0046] S103. Through the deep learning algorithm for defective product detection, identify the defects of defective products in the single frame image data, and calculate the pixel coordinate information (x, y) and scale information (w, h) of the center position of the defect part of the defective product in the image, ( x, y) corresponds to the horizontal and vertical coordinate information in the image, (w, h) corresponds to the length and width information of the defective part in the image, and uses the camera matrix to convert the coordinate information of the coordinate system into the coordi...

Embodiment 2

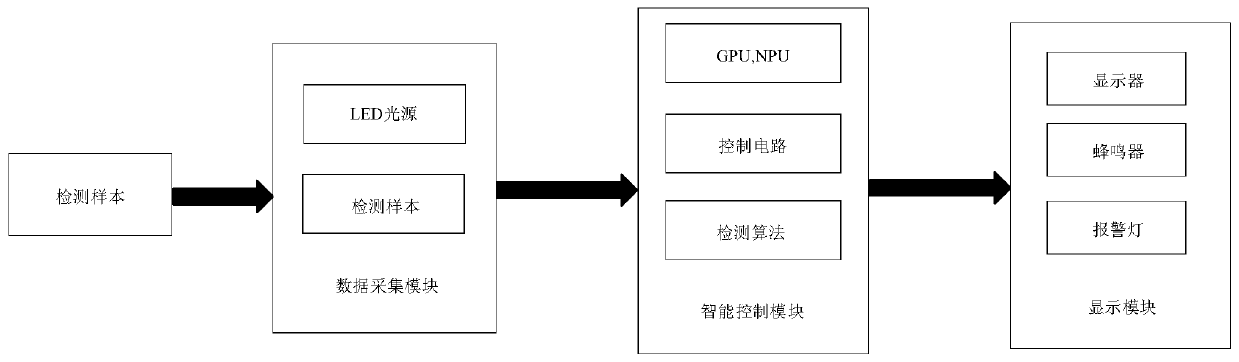

[0054] refer to figure 2 , the present disclosure also provides an intelligent visual detection system applied to the detection of defective injection molded parts, which is characterized in that it includes: a data acquisition module, an intelligent control module and a display module, the intelligent control module includes a data stream decomposition module, not Good product detection module, defective product classification module, target tracking module and statistics module;

[0055] A data acquisition module for obtaining video stream data of samples to be detected;

[0056] The data stream decomposition module decomposes the video stream data into single frame image data;

[0057] The defective product detection module, through the defective product detection deep learning algorithm, identifies the defects of defective products in a single frame of image data, and calculates the pixel coordinate information (x, y) and scale information (w, h) of the center position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com