MPS-based enterprise medium and long term production planning system and method

A production planning, medium and long-term technology, applied in the field of enterprise management, can solve problems such as unintuitive, poor presentation effect, cumbersome maintenance simulation, etc., and achieve the effect of avoiding manual modification and paper-based operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

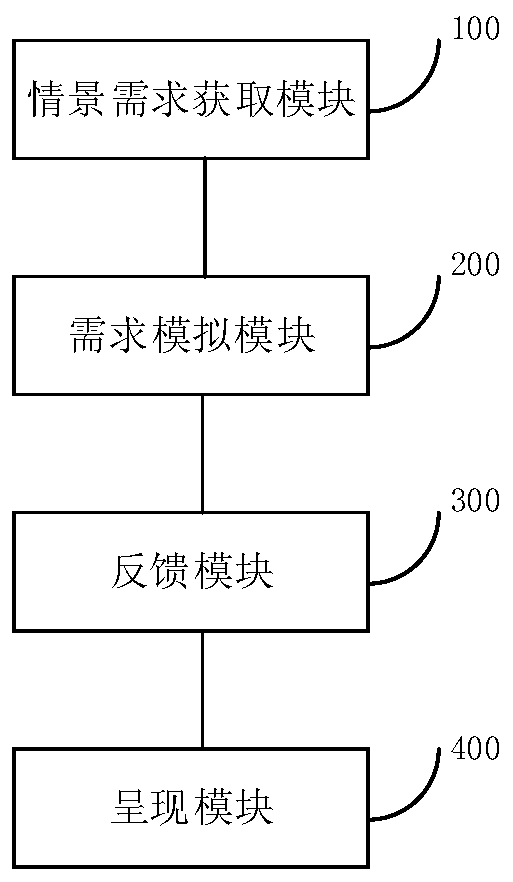

[0049] See figure 1 , figure 1 It is a schematic diagram of an MPS-based enterprise mid- and long-term production planning system provided by an embodiment of the present invention. The MPS-based enterprise medium and long-term production planning system of the present invention includes a situational demand acquisition module, a demand simulation module, a feedback module and a presentation module; the situational demand acquisition module is used to obtain situational demand information; the demand simulation module is used to Convert the preset scenarios into corresponding multiple key factors, and perform combined simulation on the key factors to obtain simulated data; the feedback module is used to obtain presentation feedback information when judging the completion of the combined simulation; the presentation module is used to obtain presentation feedback information according to the presentation The information displays the simulated data according to the presentation ...

Embodiment 2

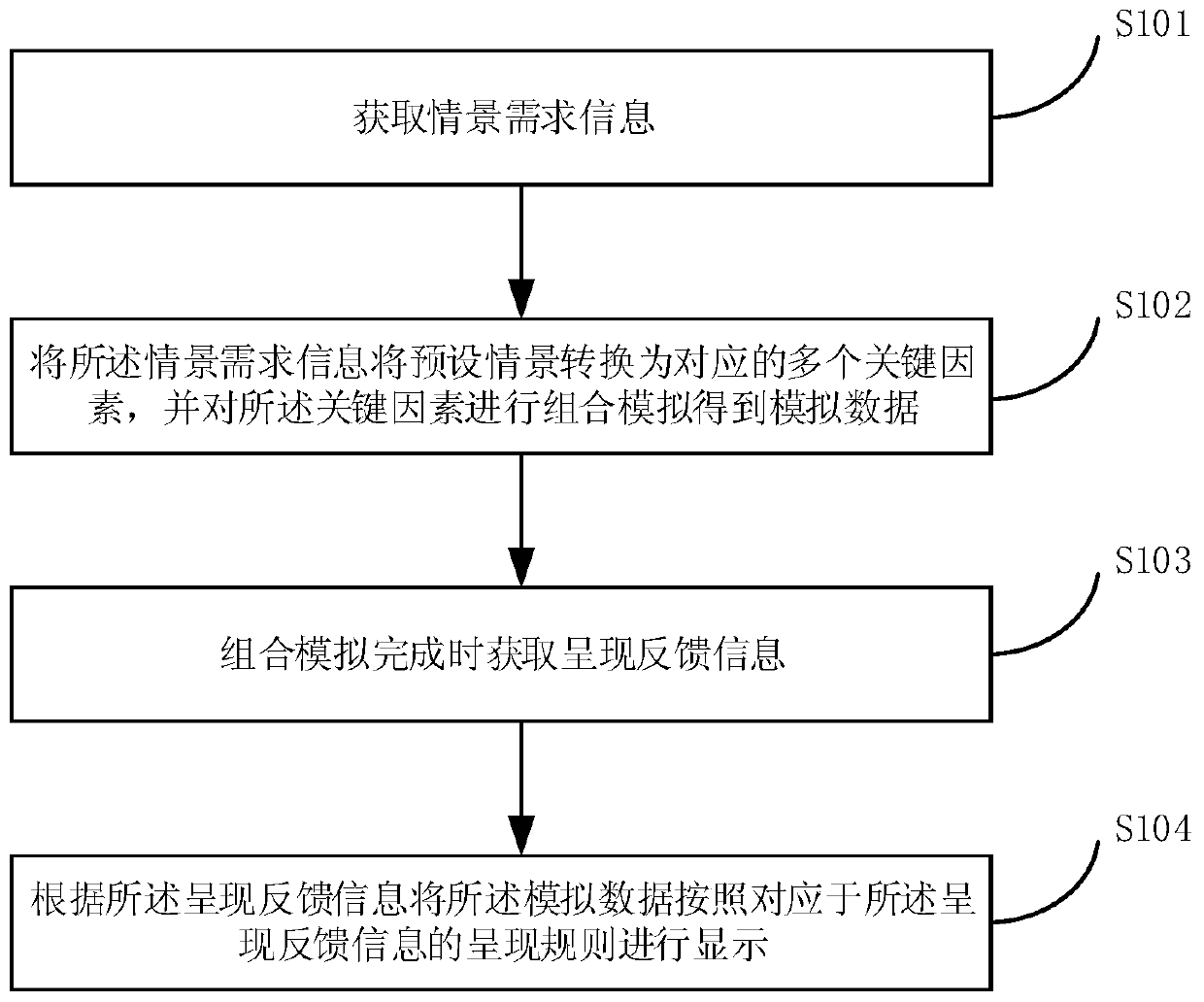

[0070] See figure 2 , figure 2 It is a flow chart of an MPS-based medium- and long-term production planning method for an enterprise provided by an embodiment of the present invention. The MPS-based medium and long-term production planning method of the present embodiment comprises the following steps:

[0071] S101. Obtain situational demand information,

[0072] S102, converting the scenario demand information into preset scenarios into corresponding multiple key factors, and performing combined simulation on the key factors to obtain simulated data; the key factors include new product and new technology information factors, market demand forecasting factors , capacity factor, yield factor or cycle factor; the combined simulation of the key factors to obtain simulated data includes:

[0073] Input one or more key factors according to the scenario requirements to obtain the product mix;

[0074] simulating the production capacity of said product mix based on said produc...

Embodiment 3

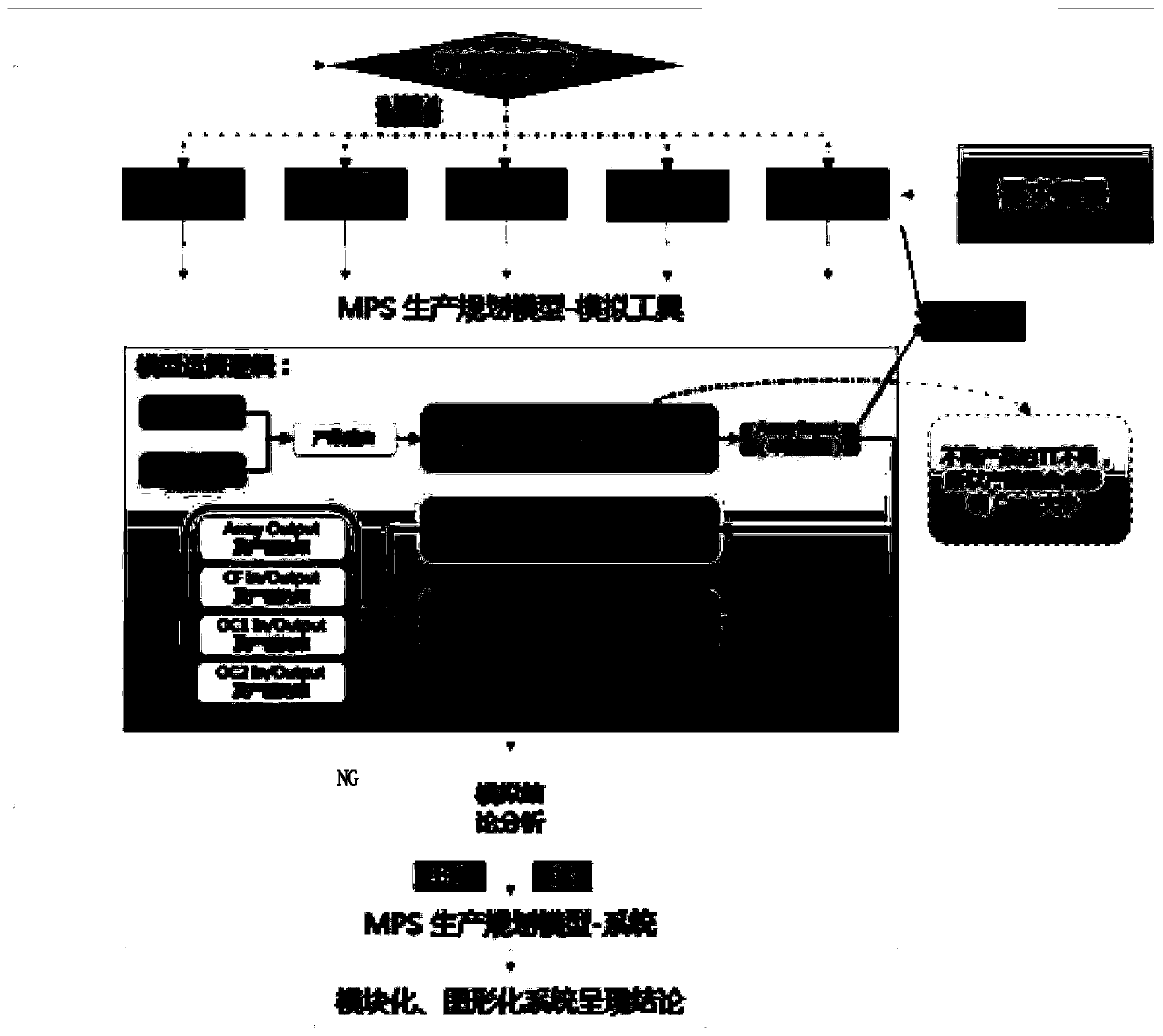

[0114] This embodiment will illustrate the specific effects of the traditional mid-to-long-term planning of enterprises and the mid-to-long-term production planning system and method of the present invention by way of comparison.

[0115] See Figure 5 , Figure 5 It is a schematic diagram of the traditional medium and long-term planning of LCD panel manufacturers. In the figure, each process and each factory are modeled separately, and each process simulation and each factory simulation require at least one manpower, which is very labor-intensive; and if the final simulation conclusion analysis results are not required, it needs to be analyzed in multiple It is very cumbersome to find problem points in the model and multiple factor tabs; and the final simulation analysis conclusion has been published by MPS paper or email, which is not intuitive and cannot be viewed in real time.

[0116] However, in the medium and long-term production planning system and method of an enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com