Method and device for automatically identifying falsification of working parameters of pollution source monitoring equipment

A technology for monitoring equipment and working parameters, which is applied in the field of automatic identification of pollution source monitoring equipment working parameters falsification, can solve the problems of unsatisfactory monitoring effect, high work intensity, low efficiency, etc., and achieve the effect of saving manpower and material resources, improving efficiency, and real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for automatically identifying falsified working parameters of pollution source monitoring equipment. The working parameters of pollution source monitoring equipment are key parameter information for equipment analysis and operation, most of which are configurable information that reflect the parameter information of the operating status of the equipment, and some are environmental Parameter information. Working parameters mainly include range and calibration related parameters (calibration concentration, calibration original value, calibration time, calibration coefficient).

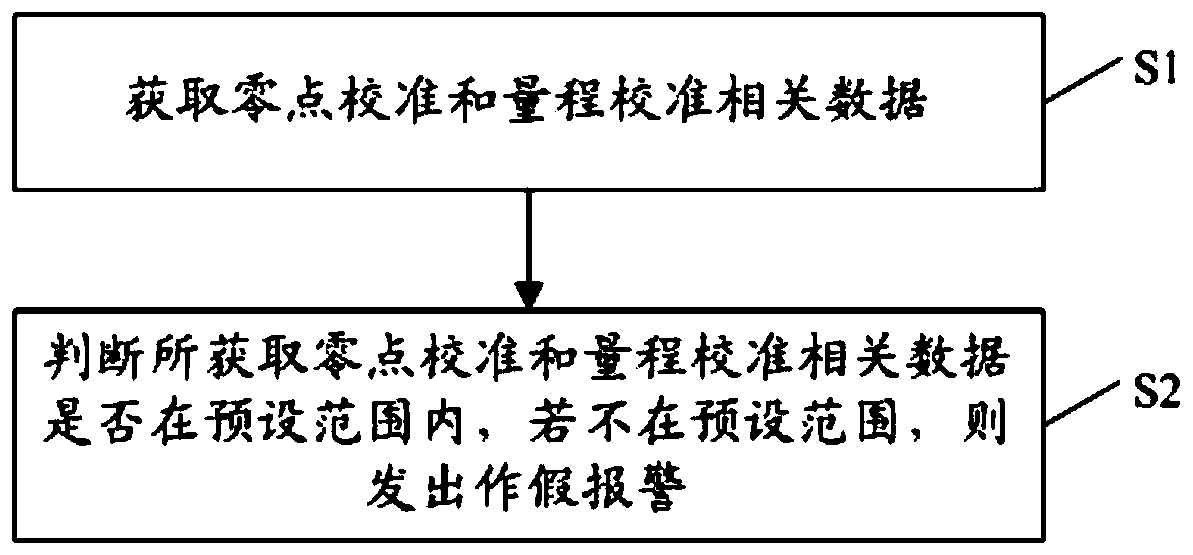

[0038] Such as figure 1 As shown, the method includes the following steps:

[0039] S1, obtaining data related to zero point calibration and span calibration;

[0040] S2, judging whether the acquired data related to zero point calibration and span calibration are within a preset range, and if not within a preset range, issuing a false alarm.

[0041] During th...

Embodiment 2

[0056] This embodiment provides a device for automatically identifying fraudulent working parameters of pollution source monitoring equipment that implements the method of Embodiment 1. The device includes:

[0057] Data acquisition module: acquire data related to zero point calibration and span calibration;

[0058] Judging execution module: judging whether the obtained data related to zero calibration and span calibration are within the preset range, and if not, a false alarm will be issued.

[0059] Wherein, the data related to zero point calibration acquired by the data acquisition module includes zero point calibration time and zero point calibration coefficient.

[0060] Correspondingly, the judging execution module judges whether the acquired zero-point calibration-related data is within the preset range, specifically including:

[0061] Determine whether the zero-point calibration period is within the preset period range by the zero-point calibration time;

[0062] J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com