Solid-sealed polar pole structure of load switch-fuse combined electric appliance

A technology for load switches and combined electrical appliances, applied in electrical switches, high-voltage air circuit breakers, high-voltage/high-current switches, etc., can solve the problems of large size, difficult installation and disassembly, and small application range, and achieve small size and easy installation. and disassembly, the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

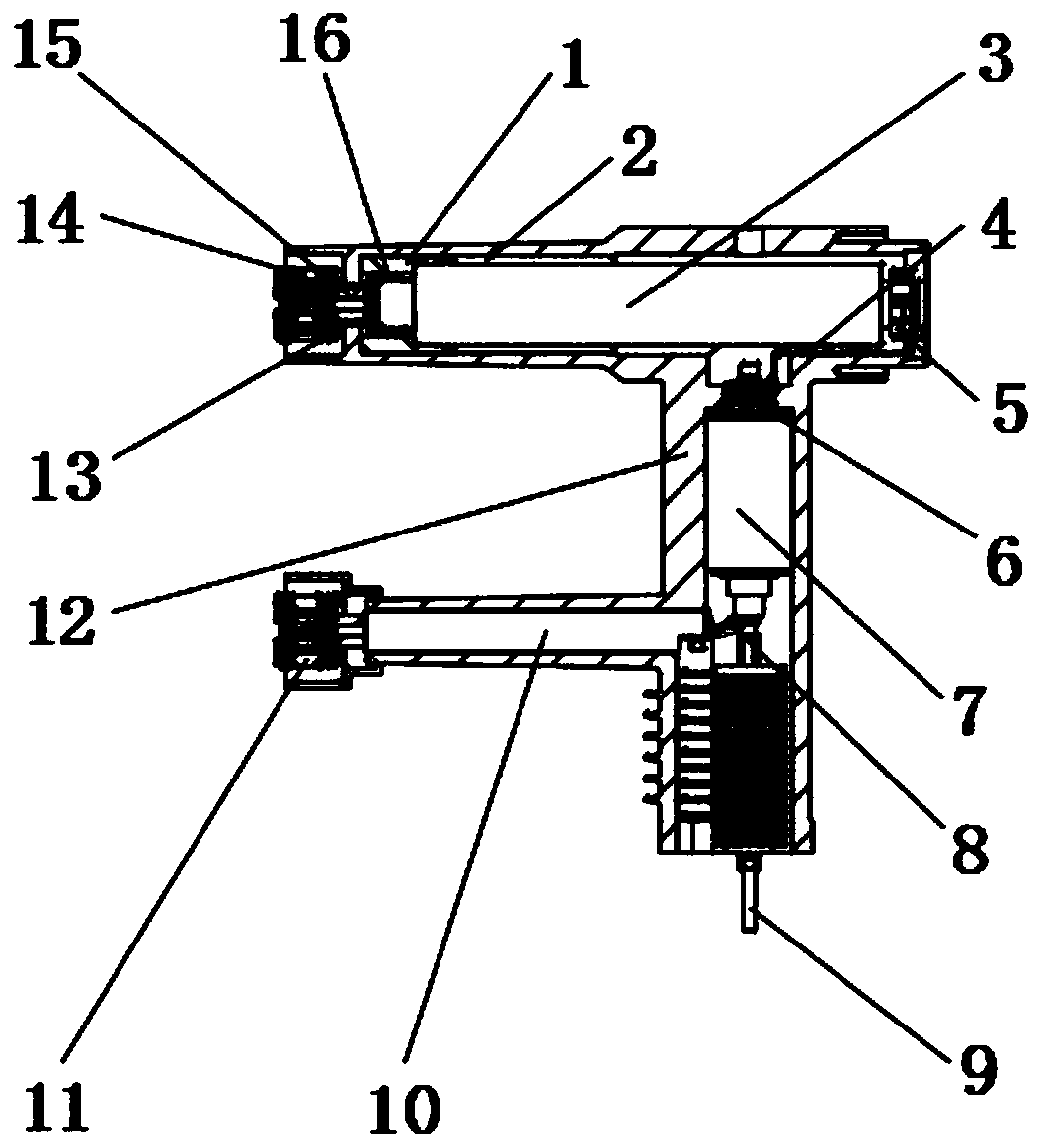

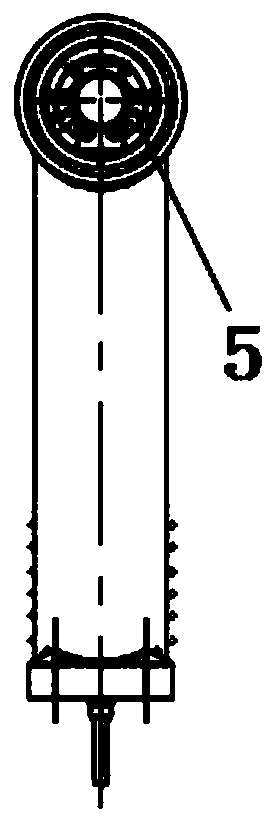

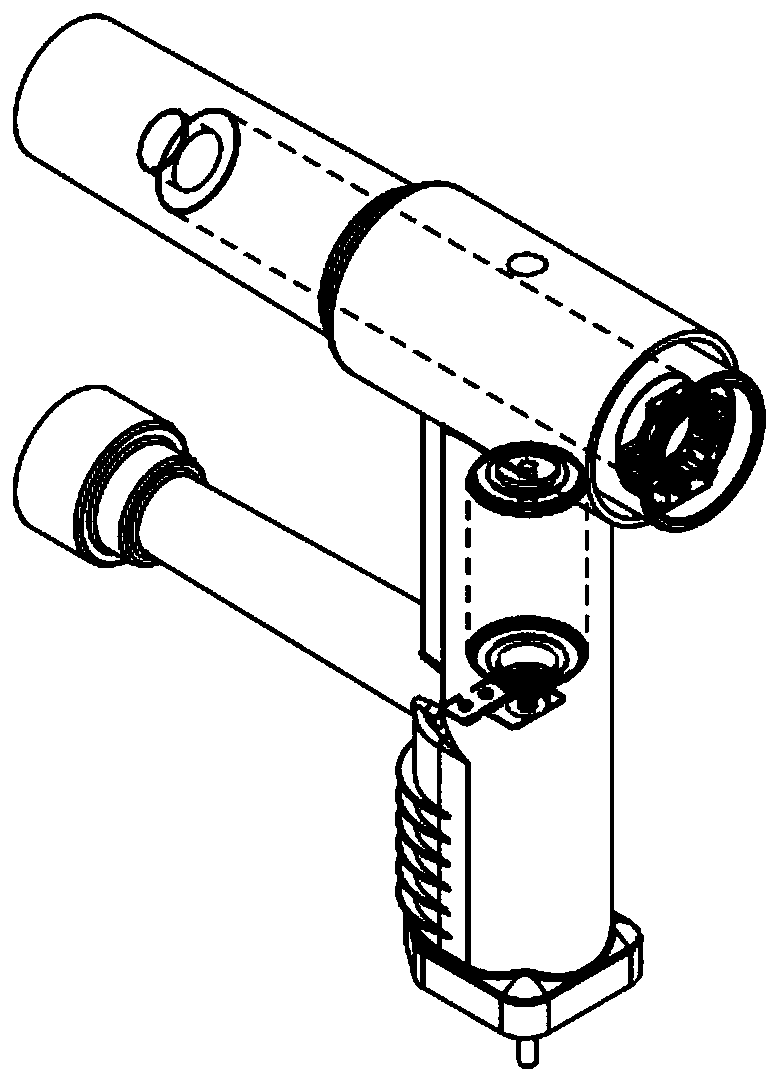

[0018] As shown in the accompanying drawings, an embedded pole structure of a load switch-fuse combination electric appliance includes a fuse 3 and an embedded pole 12, and the outer side of the fuse 3 is integrally cast with the embedded pole Formed fuse cavity 2, the left and right sides of the fuse 3 are respectively equipped with a fuse clamp 16 and a conductive clamp 5, the outer side of the fuse clamp 16 is equipped with a guide sleeve 1, and the outer side of the fuse clamp 16 is equipped with an upper Contact arm 15, the upper contact arm 15 is equipped with a plum blossom contact 14, the outer side of the upper contact arm 15 is equipped with a positioning part 13, and the conductive part 6 is installed under the fuse 3, and the conductive part 6 passes through A soft connection 4 is connected to the conductive clip 5, a vacuum interrupter 7 is installed under the conductive member 6, and the vacuum interrupter 7 is connected to the lower contact arm 10 by b soft conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com