A flue-cured tobacco curing method that can effectively improve the quality of iron-poisoned tobacco leaves

A curing method and tobacco leaf technology are applied in the directions of tobacco, tobacco preparation, application, etc., which can solve the problems of income loss of tobacco farmers, affecting the quality of tobacco leaves, poor ventilation, etc., reducing economic losses, achieving significant improvement effects, and reducing restrictiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

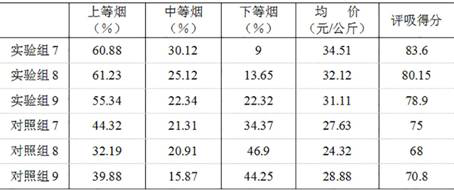

Examples

Embodiment 1

[0028] S100: In Ziwu Town, Chuxiong City, the central tobacco leaves of KRK26 iron-poisoned flue-cured tobacco with white rib, slender and chlorotic leaves and most of the hairs falling off were harvested and woven as usual.

[0029] S200: Press 43.5kg / m of woven tobacco leaves 3 The density of the smoke should be filled to more than 95% of the volume of the air-flow descending intensive roasting room, and it should be roasted.

[0030] S300: Including the initial yellowing stage and the late yellowing stage. In the initial yellowing stage, the dry bulb temperature was increased from room temperature to 37 °C at a heating rate of 1 °C / h, and the wet bulb temperature was adjusted from room temperature to 36.5 °C to stabilize dry and wet bulbs. The tobacco leaves in the high temperature area were baked for 22 hours until 80% of the tobacco leaves in the high temperature area turned yellow; then in the late stage of yellowing, at a heating rate of 1°C / 3h, the dry bulb temperature...

Embodiment 2

[0034] S100: In Ziwu Town, Chuxiong City, the central tobacco leaves of KRK26 iron-poisoned flue-cured tobacco with white rib, slender and chlorotic leaves and most of the hairs falling off were harvested and woven as usual.

[0035] S200: Press 43.5kg / m of woven tobacco leaves 3 The density of the smoke should be filled to more than 95% of the volume of the air-flow descending intensive roasting room, and it should be roasted.

[0036]S300: Including the initial yellowing stage and the late yellowing stage. At the initial stage of yellowing, the dry bulb temperature was increased from room temperature to 38 °C at a heating rate of 1 °C / 1.5 h, and the wet bulb temperature was adjusted from room temperature to 37 °C to stabilize dry and wet conditions. The temperature of the bulb was baked for 23 hours until 80% of the tobacco leaves in the high temperature area turned yellow; then in the late stage of yellowing, the dry bulb temperature was raised to 42°C at a heating rate of ...

Embodiment 3

[0040] S100: In Ziwu Town, Chuxiong City, the central tobacco leaves of KRK26 iron-poisoned flue-cured tobacco with white rib, slender and chlorotic leaves and most of the hairs falling off were harvested and woven as usual.

[0041] S200: Press 43.5kg / m of woven tobacco leaves 3 The density of the smoke should be filled to more than 95% of the volume of the air-flow descending intensive roasting room, and it is to be roasted.

[0042] S300: including the initial yellowing stage and the late yellowing stage. In the initial yellowing stage, the dry bulb temperature is increased from room temperature to 38 °C at a heating rate of 1 °C / h, and the wet bulb temperature is adjusted from room temperature to 37 °C to stabilize dry and wet bulbs. The tobacco leaves in the high temperature area were baked for 24 hours until 80% of the tobacco leaves in the high temperature area turned yellow; then in the late stage of yellowing, at a heating rate of 1°C / 3h, the dry bulb temperature was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com