Method for producing a MEMS structure and corresponding MEMS structure

A structure and functional layer technology, applied in the manufacture of microstructure devices, processes for producing decorative surface effects, microstructure technology, etc., can solve problems such as unfavorable process steps, inability to remove oxides, etc., and achieve high process flexibility. The effect of stable and tight, effective and rapid construction of closed areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the drawings, the same reference numerals are used to indicate the same or the same elements.

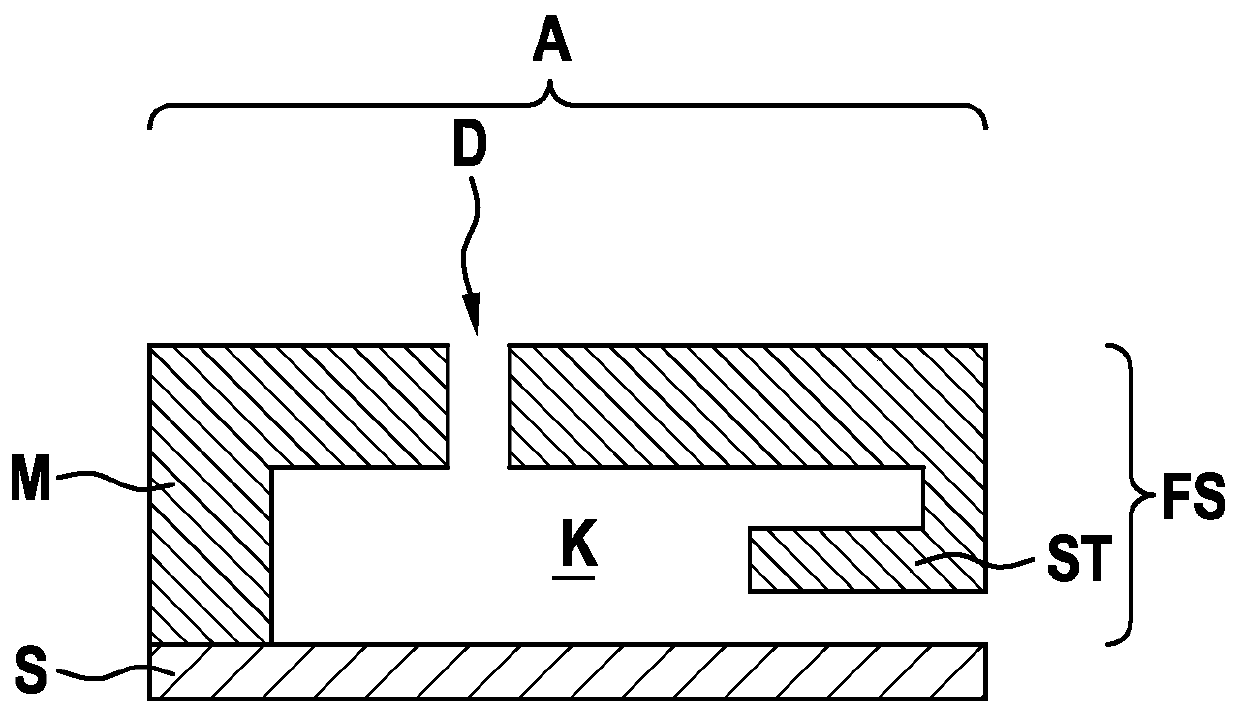

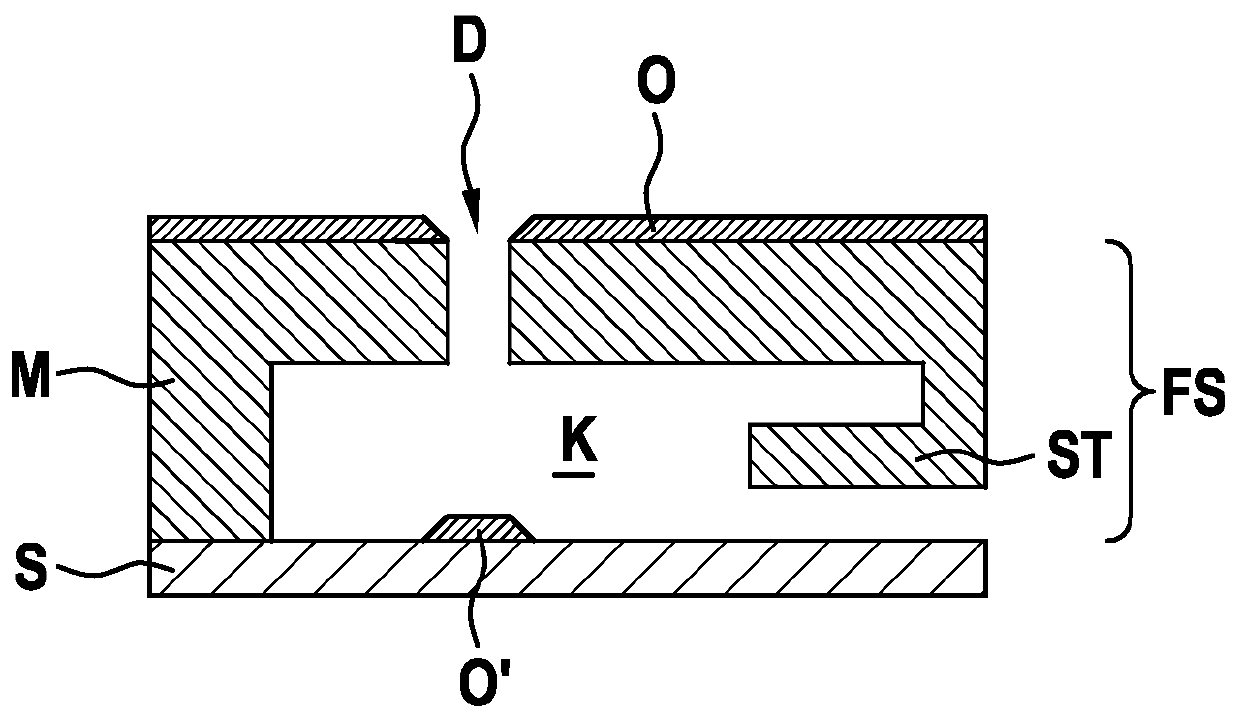

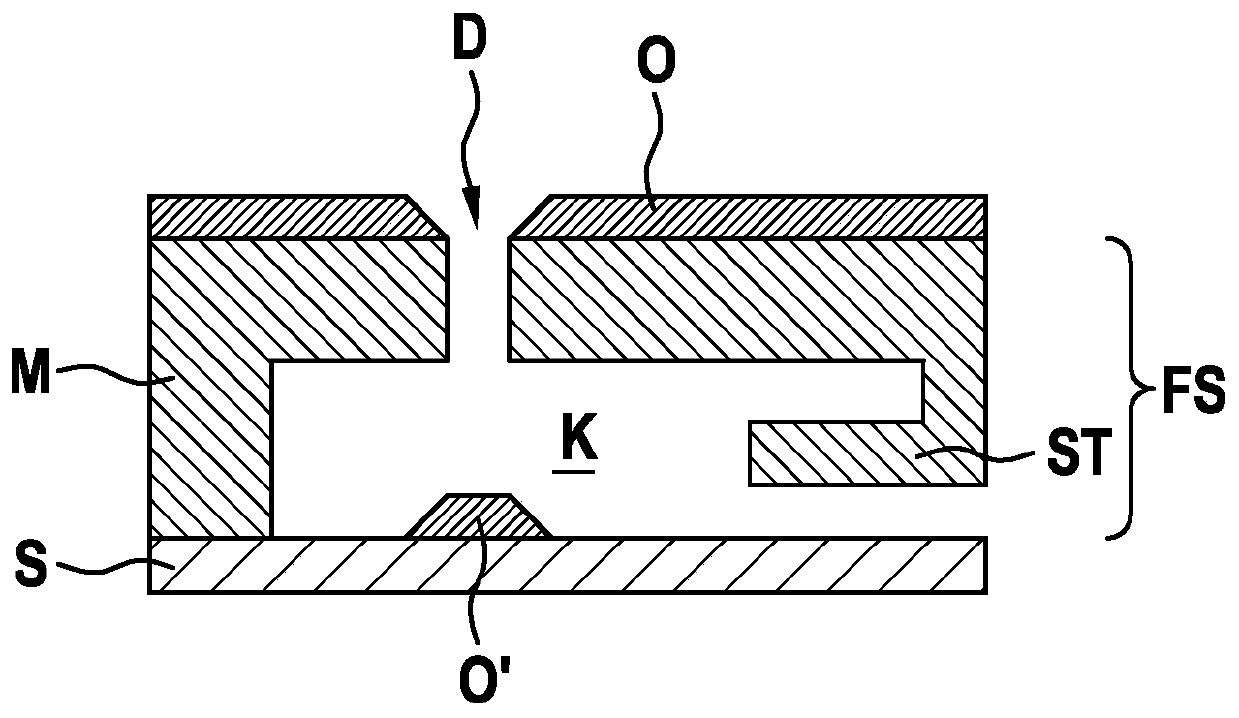

[0058] 1a)-g) are schematic partial cross-sectional views for explaining the manufacturing method for the MEMS structure according to the first embodiment of the present invention.

[0059] According to Figures 1a)-g), a substrate S is provided on which a micromechanical functional layer assembly FS is applied, which functional layer assembly has one or more functional layers. The substrate S is, for example, a silicon wafer substrate, and the functional layer component FS includes, for example, one or more functional layers composed of polysilicon, oxide, nitride, metal, and the like. The functional layer component FS has a cavity K which has a smaller lateral extension than the functional layer component FS. According to FIG. 1a), the through opening is exposed toward the outside of the functional layer assembly FS.

[0060] The cavity K is spanned by a membrane M for absolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com