Grid type sewage treatment apparatus

A sewage treatment device and grid technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. Clogging and other problems, to achieve the effect of improving filtration treatment, reducing labor costs, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

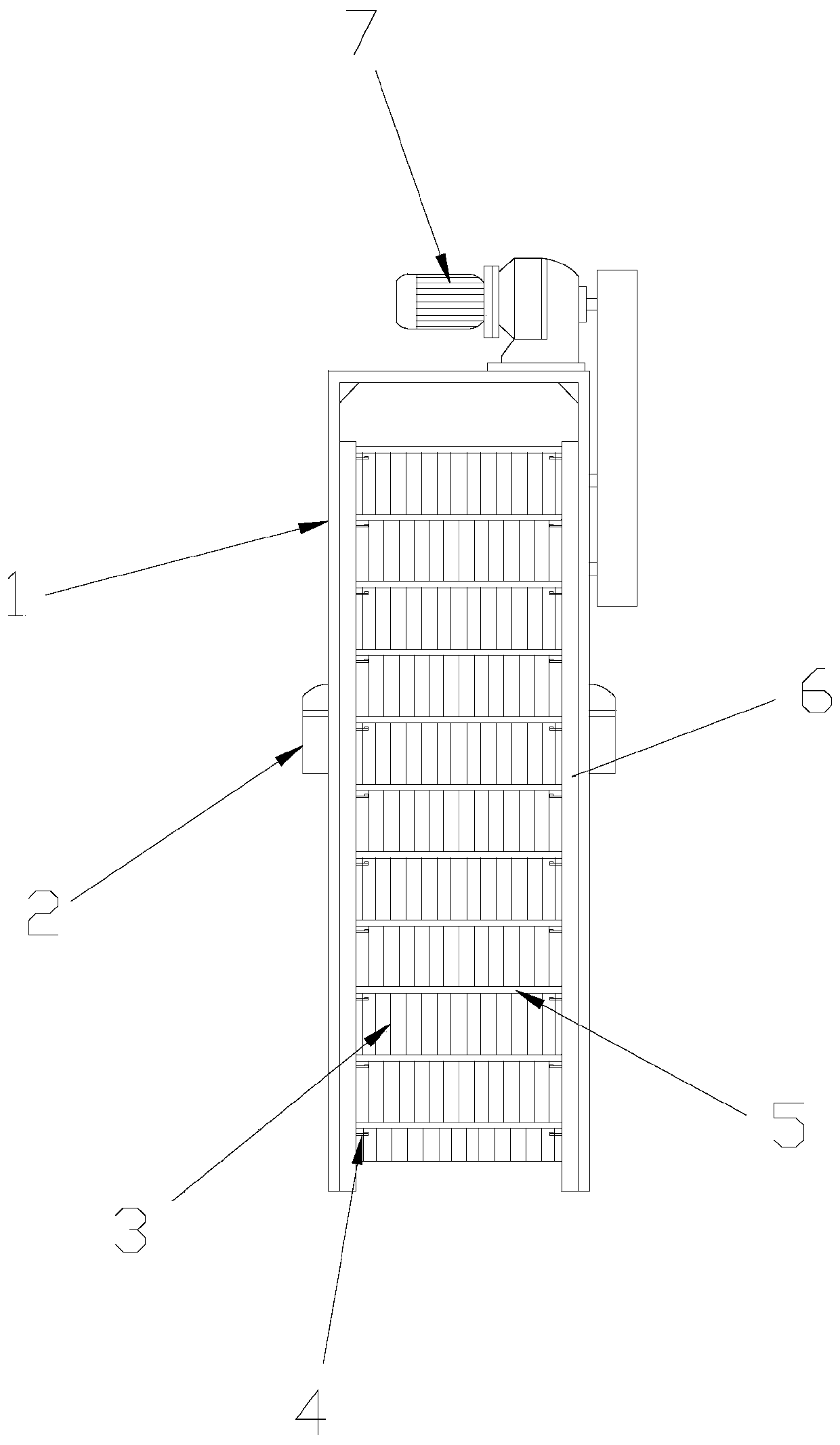

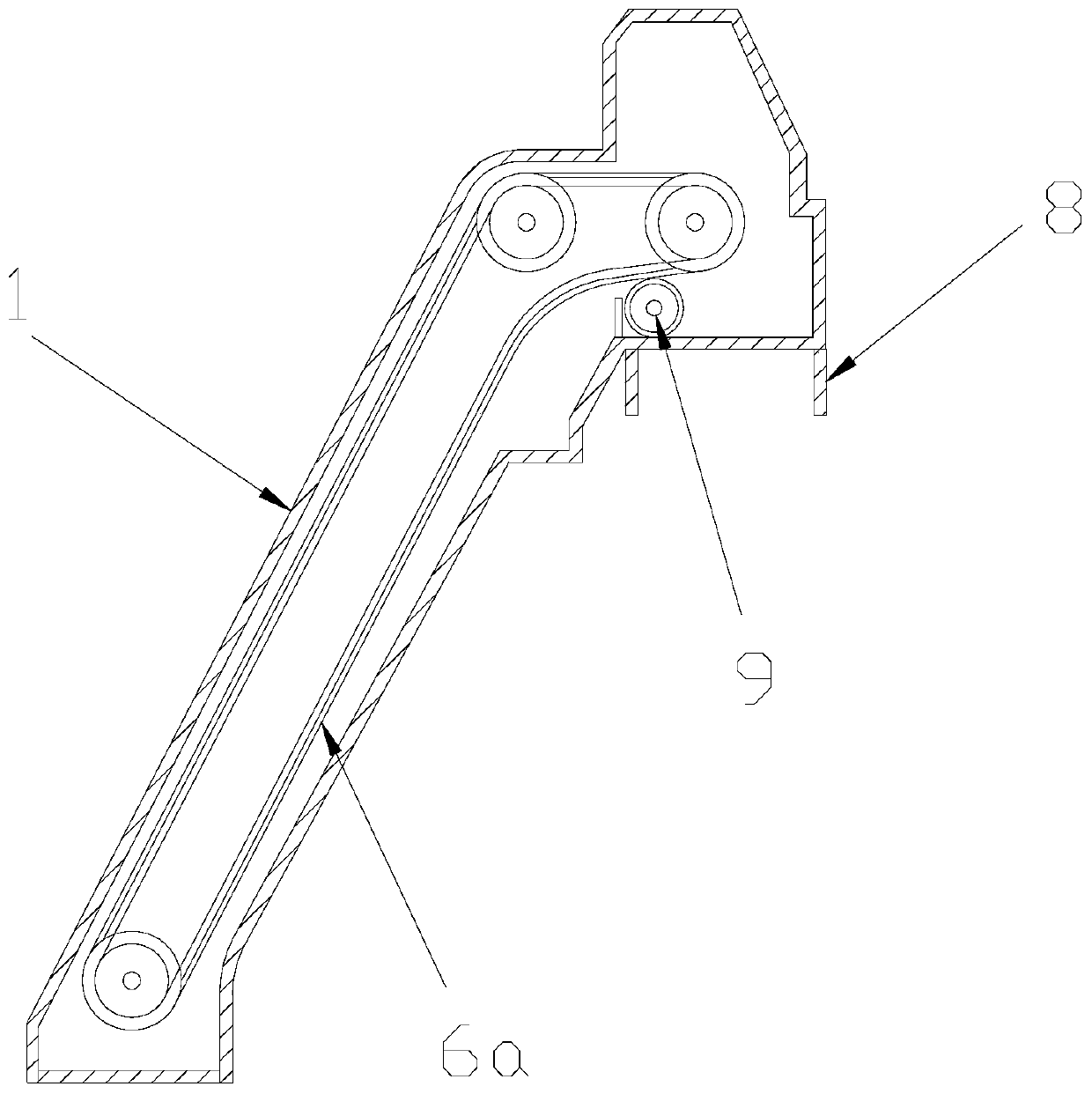

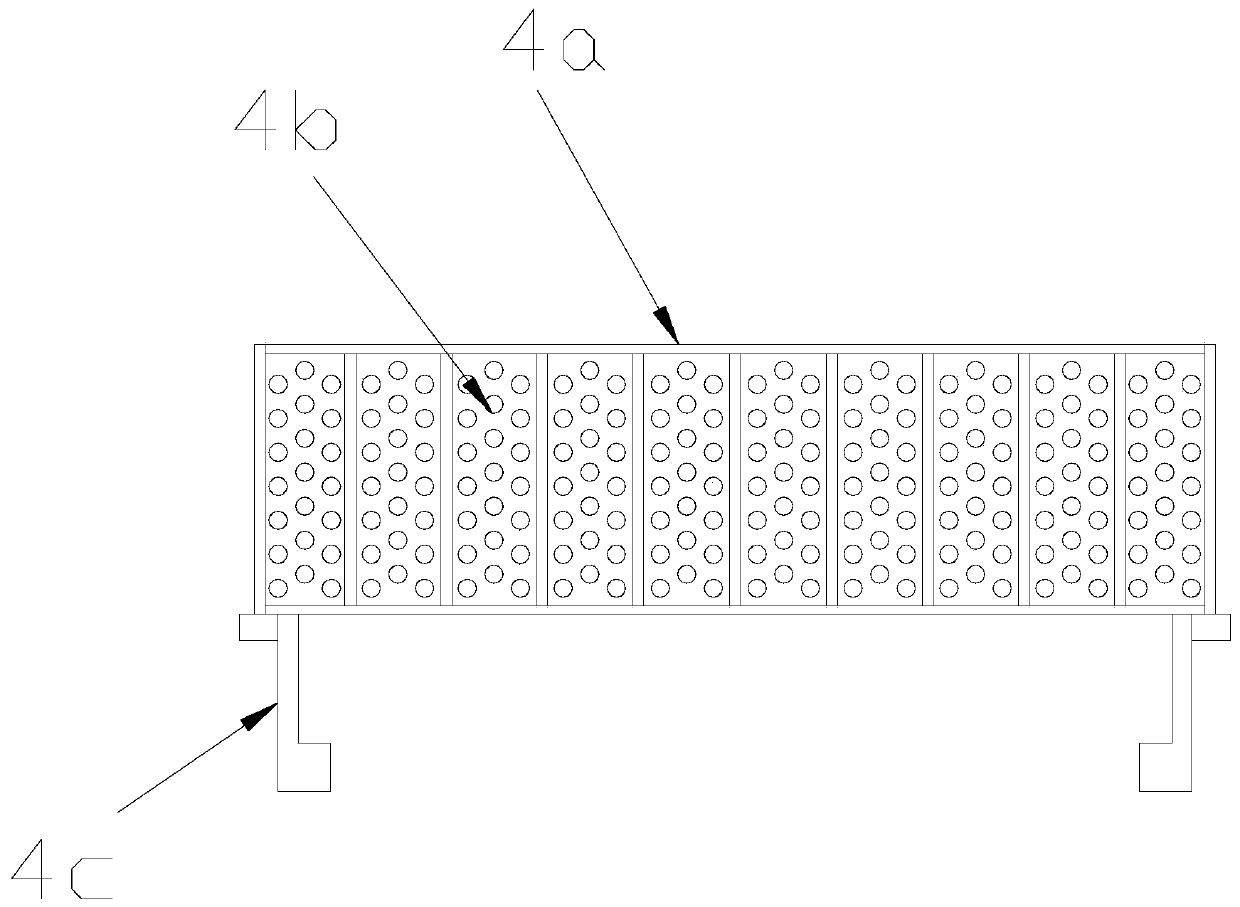

[0028] see Figure 1-Figure 5 , the present invention provides a grid-type sewage treatment device, the structure of which includes a grid sewage cleaning machine 1, a bracket 2, a grid bar 3, a secondary decontamination mechanism 4, rake teeth 5, a traction chain 6, a driving device 7, The slag discharge conduit 8, the rejecting mechanism 9, the grid sewage cleaning machine 1 is provided with a bracket 2 on the surface, the grid sewage cleaning machine 1 and the bracket 2 are welded by electric welding, the grid sewage cleaning machine 1 A driving device 7 is installed on the top, and a traction chain 6 is arranged on the inner side of the grid sewage cleaning machine 1, and the described grid sewage cleaning machine 1 and the traction chain 6 are movably connected, and the traction chain 6 There is a grid bar 3 on the inner side, the traction chain 6 and the grid bar 3 are tenon-connected, and the rake teeth 5 are arranged on the front surface of the grid bar 3, and the grid...

Embodiment 2

[0036] see Figure 1-Figure 7 , the present invention provides a grid-type sewage treatment device, the rejecting mechanism 9 is composed of a drum 9a, a rotating shaft 9b, a rejecting bar 9c, a brush 9d, and a linkage gear 9e, and the left and right ends of the drum 9a are A rotating shaft 9b is provided, the cylinder 9a is fixedly connected to the rotating shaft 9b, the surface of the cylinder 9a is provided with a rejecting strip 9c, the cylinder 9a is glued to the rejecting strip 9c, and the surface of the rejecting strip 9c is provided with There is a brush 9d, the rejecting bar 9c is connected with the brush 9d, the surface of the rotating shaft 9b is provided with a linkage gear 9e, and the rotation shaft 9b is fixedly connected with the linkage gear 9e.

[0037] The surface of the rotating shaft 9b is provided with a positioning frame 9b1, the rotating shaft 9b and the positioning frame 9b1 are connected by a bearing ring 9b2, the top of the positioning frame 9b1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com