Environment-friendly waste gas treatment device

An exhaust gas treatment device and an environmentally friendly technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of substandard, short service life, and failure to achieve the expected effect of exhaust gas purification, and achieve thorough improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

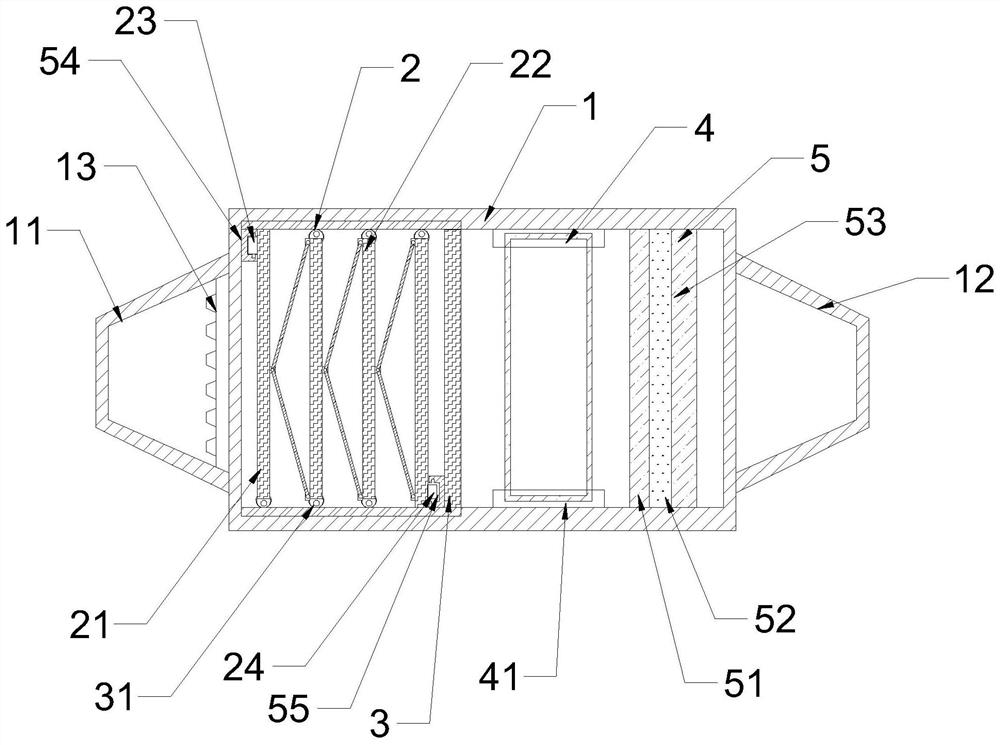

[0018] Such as Figure 1 to Figure 3 As shown, the present invention is an environmentally friendly waste gas treatment device, which is characterized in that it includes a device body 1, an adjustment filter assembly 2, a central filter plate 3, a filter drum filter element 4 and a purification layer 5;

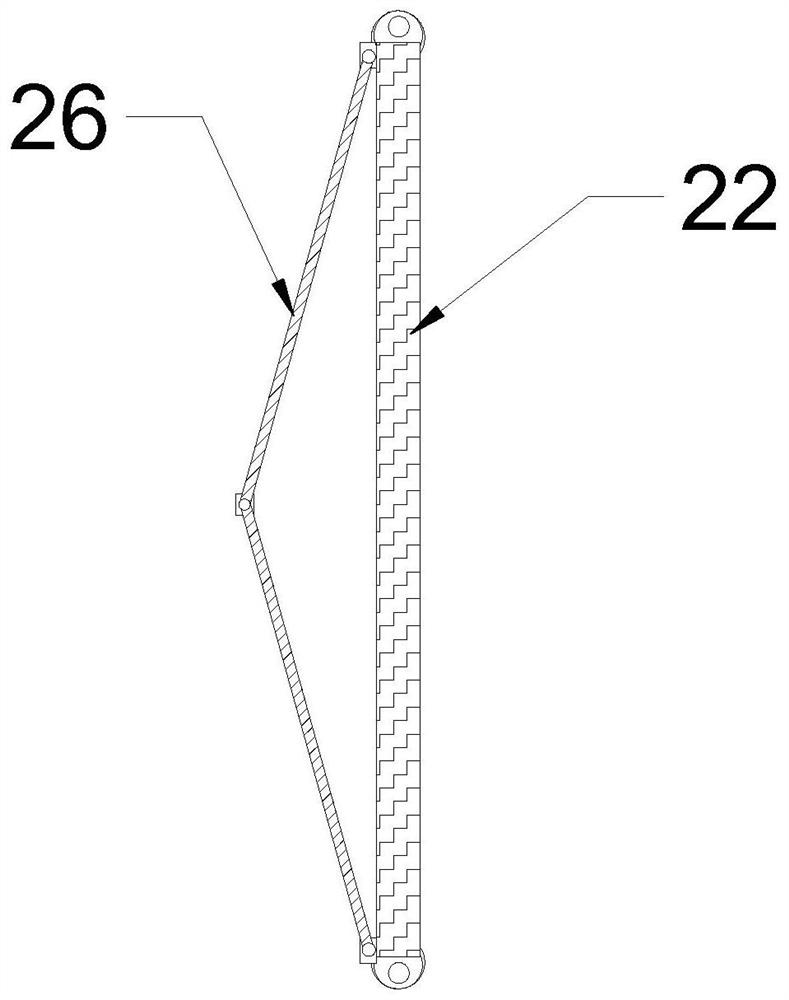

[0019] The purification layer 5 includes a filter element layer one 51, a drying layer 52 and a filter element layer two 53, and the adjustment filter assembly 2 includes a longitudinal filter plate one 21 and a longitudinal filter plate two 22;

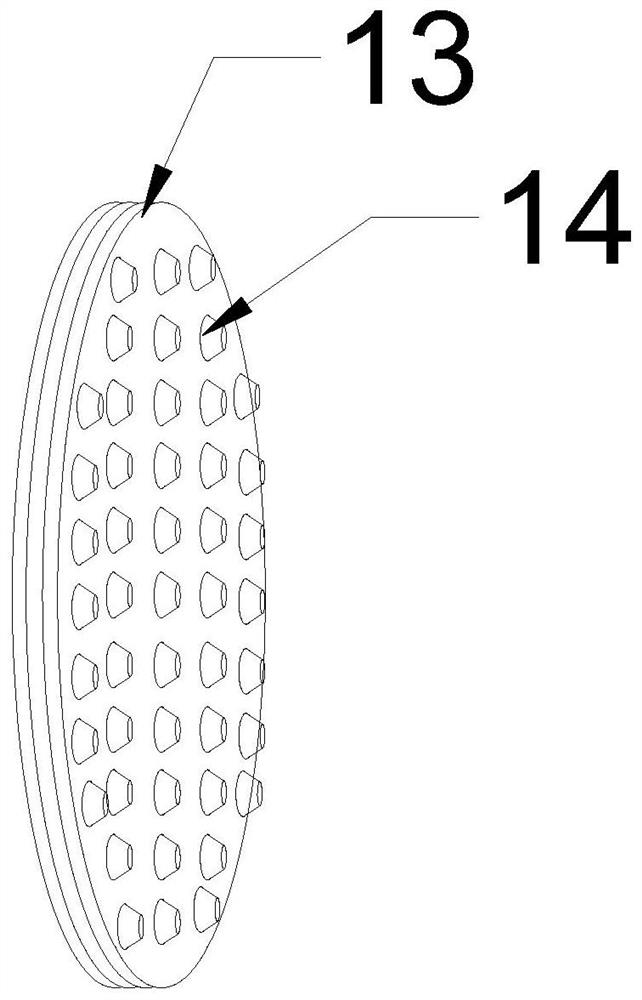

[0020] The two sides of the equipment body 1 are correspondingly provided with a purification inlet pipe 11 and a purification outlet pipe 12. The connection between the equipment body 1 and the purification inlet pipe 11 is sealed with a porous filter plate 13. The inside of the equipment body 1 is separated by a filter dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com