Concrete vibrating device for cast-in-place ballastless track bed construction

The technology of a vibrating device and a ballast bed is applied in the field of vibrating devices for railway engineering construction, which can solve the problems of low construction accuracy and increased construction cost, and achieve the effects of good vibration reduction effect, improved construction accuracy and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

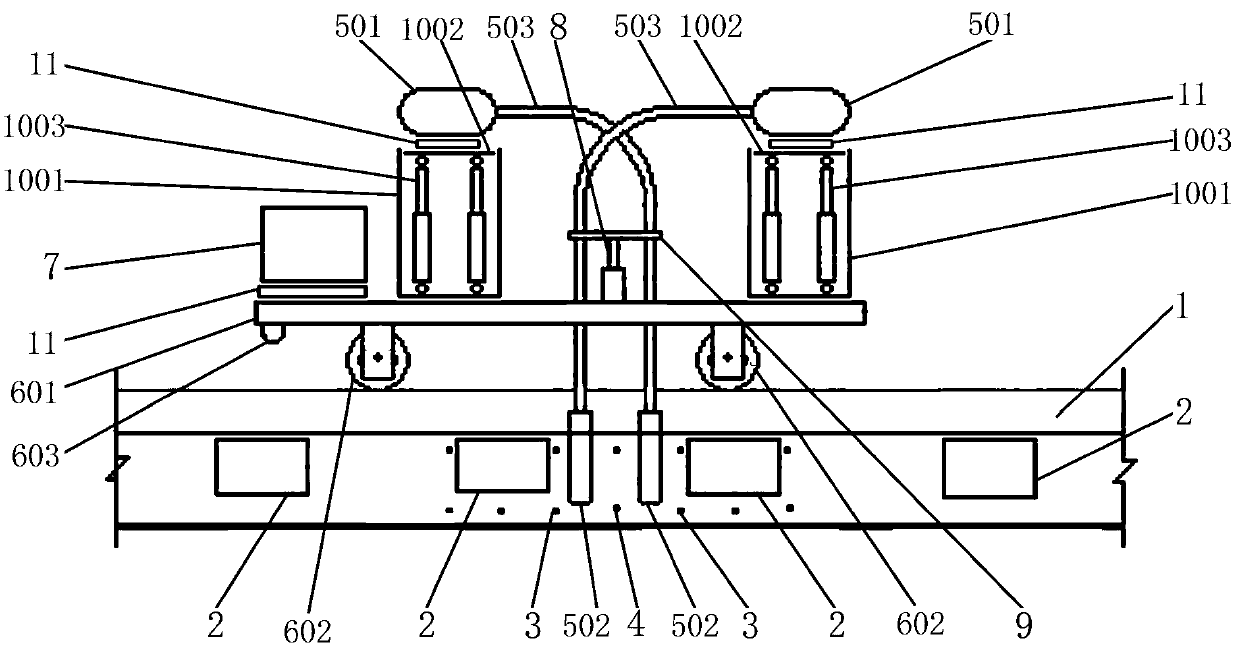

[0025] A concrete vibrating device for the construction of cast-in-place ballastless beds includes two tool rails 1 and several rows of sleepers 2 distributed left and right; two adjacent rows of sleepers 2 are provided with two rows of front-to-rear and laterally distributed guards. There is a row of structural steel bars 4 placed in the same direction as the two rows of anti-cracking structure bars 3, and there are operating gaps between the two rows of anti-cracking structure bars 3 and the structural steel bars 4; It includes eight plug-in vibrators and an electric flat car that runs on two tool rails 1 in the left-right direction; the plug-in vibrator includes a vibration motor 501, a vibrating rod 502, and a soft vehicle connected between the two. Axle tube 503; The electric flat car includes a frame 601, a stepping motor and a number of rail wheels 602, and its stepping distance is equal to the distance between two adjacent rows of sleepers 2;

[0026] The upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com