Safe anti-overflow inspection well cover

An anti-overflow and inspection well cover technology, which is applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as insufficient safety, damage to well covers, explosion incidents, etc., and achieve the effect of improving safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

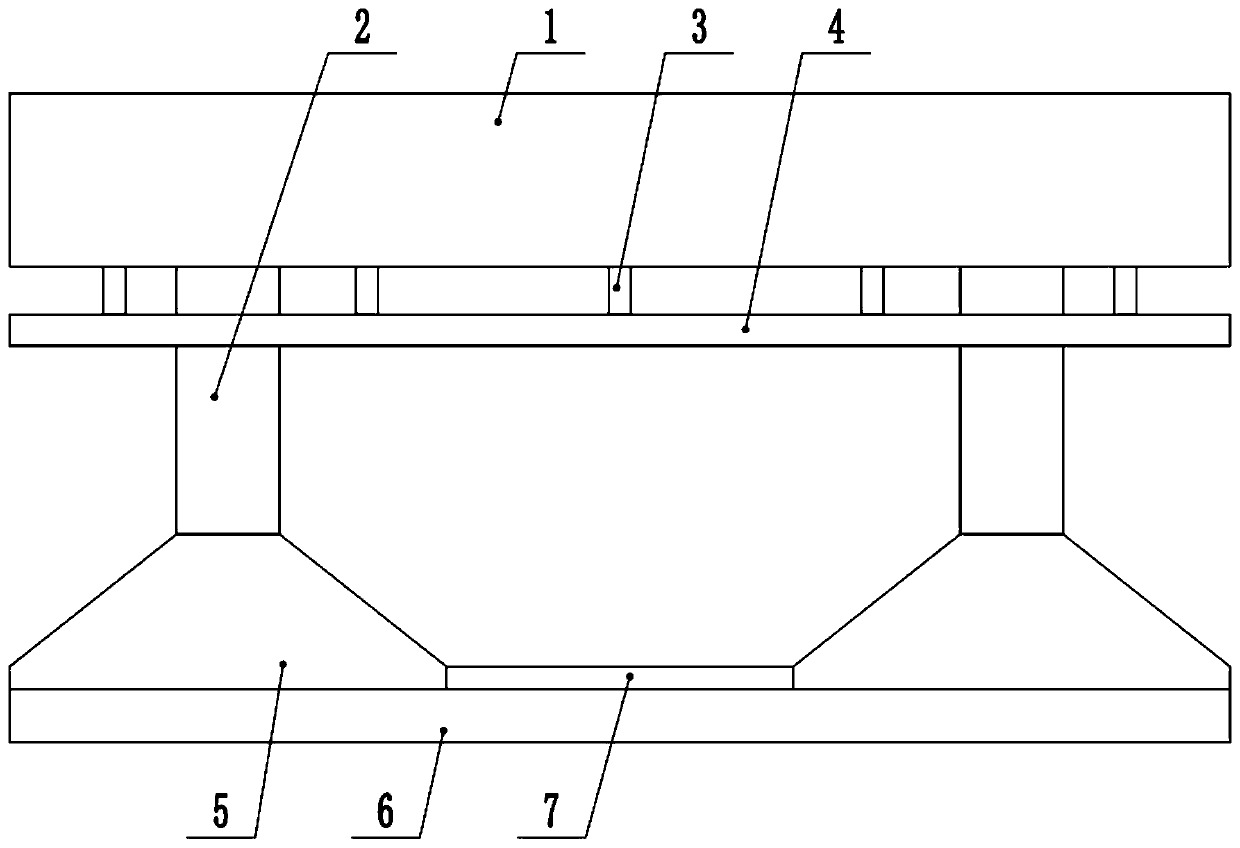

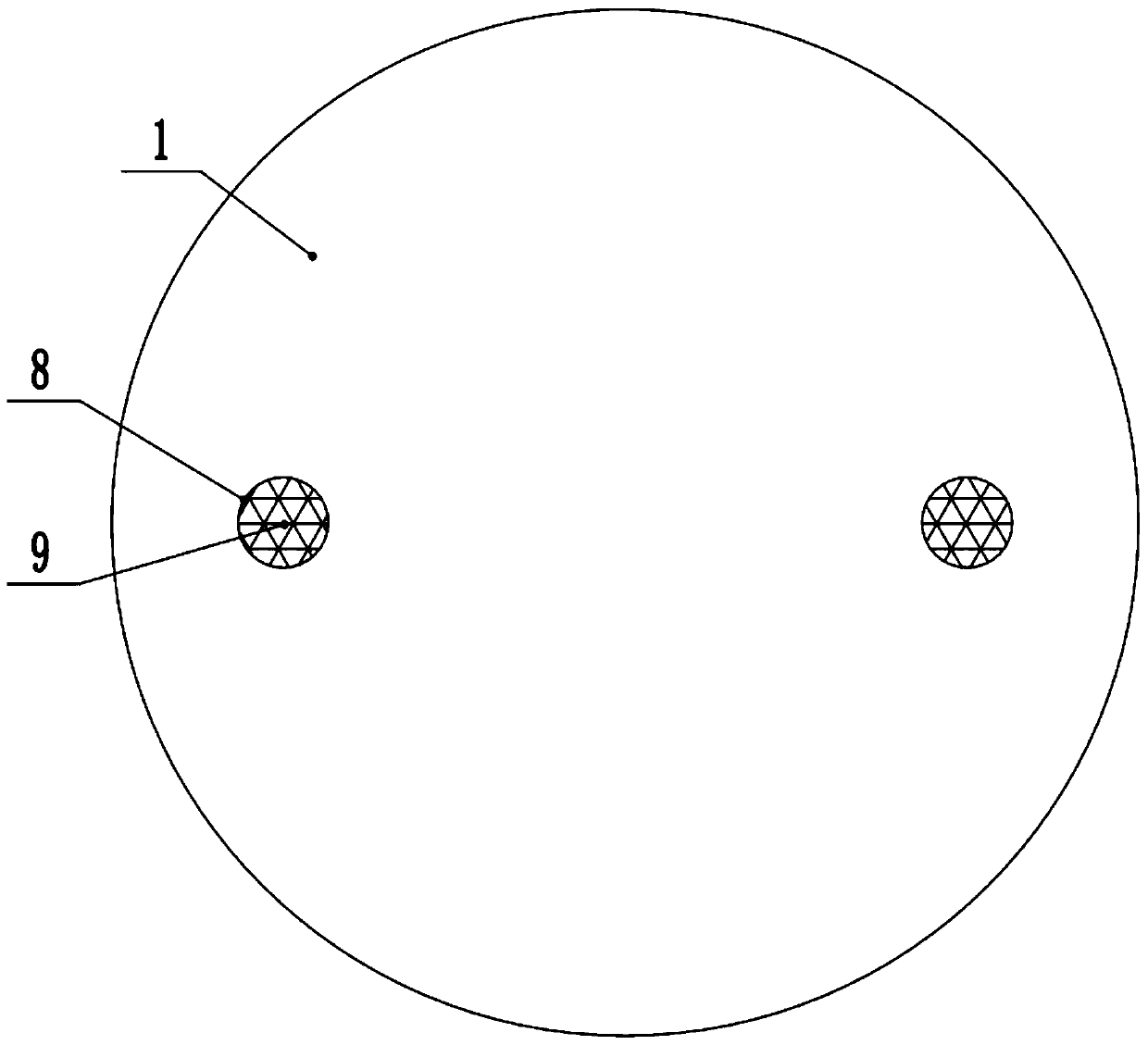

[0028] See Figure 1-5 , A safety and overflow-proof manhole cover, comprising a top cover 1, a support device is provided under the top cover 1, two drain holes 8 penetrate through the top cover 1, and the top of the drain hole 8 is fixed with The first block 9. The bottom end of the top cover 1 is located at the drain hole 8 and is fixedly connected to the drain pipe 2, the bottom end of the drain pipe 2 is fixedly connected to the water collecting cover 5, and the bottom end of the water collecting cover 5 is fixedly connected to the bottom cover 6, one of the two water collecting covers 5 The connecting seat 7 is fixedly connected between, and an overflow prevention mechanism is provided in the downpipe 2.

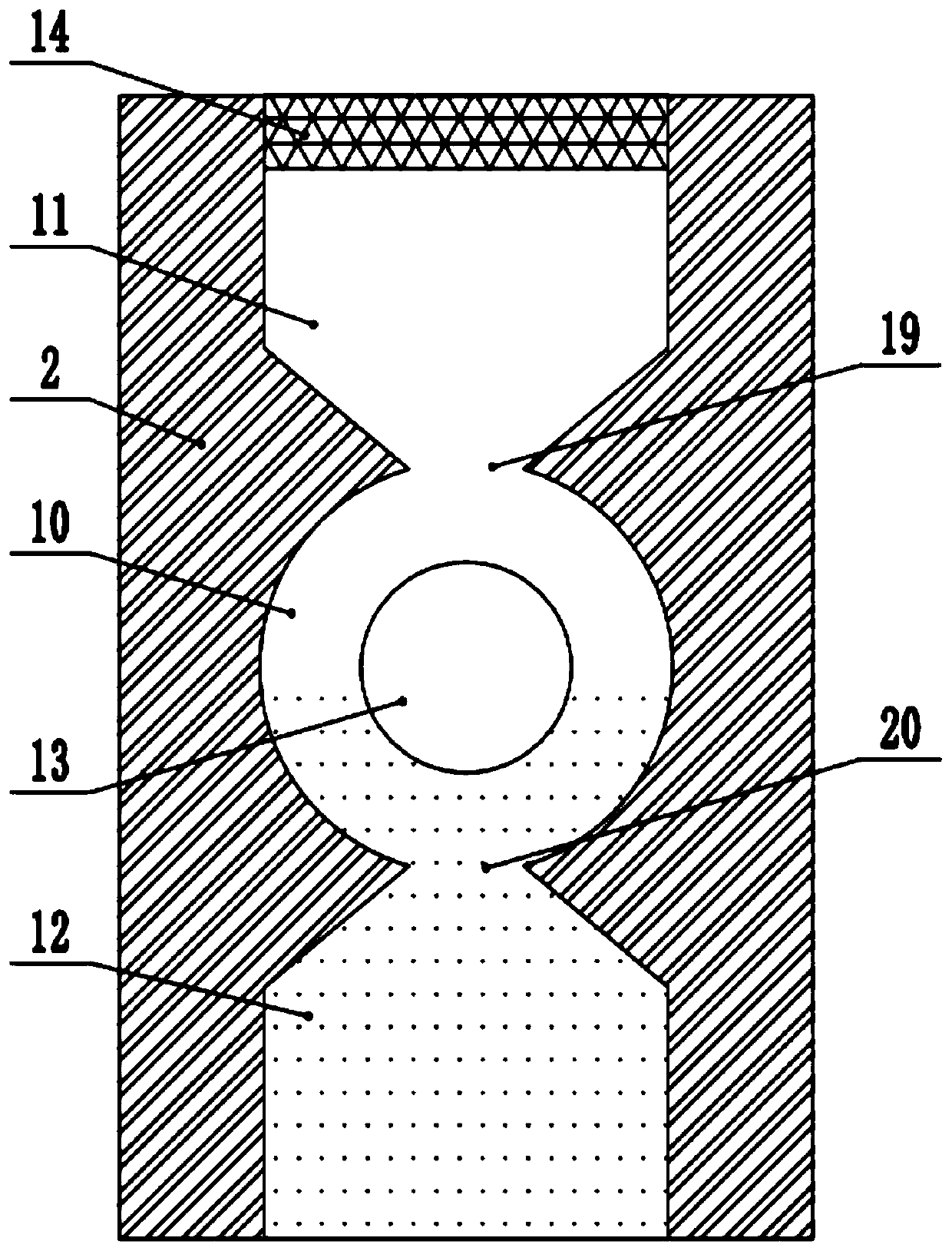

[0029] The overflow prevention mechanism includes a water inlet cavity 11, an intermediate cavity 10, and a water outlet cavity 12 opened in the bottom cover 6. The water inlet cavity 11, the intermediate cavity 10, and the water outlet cavity 12 are arranged in order fr...

Embodiment 2

[0032] See Figure 1-5 , A safety and overflow-proof manhole cover, comprising a top cover 1, a support device is provided under the top cover 1, two drain holes 8 penetrate through the top cover 1, and the top of the drain hole 8 is fixed with The first block 9. The bottom end of the top cover 1 is located at the drain hole 8 and is fixedly connected to the drain pipe 2, the bottom end of the drain pipe 2 is fixedly connected to the water collecting cover 5, and the bottom end of the water collecting cover 5 is fixedly connected to the bottom cover 6, one of the two water collecting covers 5 The connecting seat 7 is fixedly connected between, and an overflow prevention mechanism is provided in the downpipe 2.

[0033] The supporting device includes a base 4, the base 4 is circular, the top of the base 4 is fixedly connected with a plurality of supporting columns 3, the top of each supporting column 3 is fixedly connected with a fixing sleeve 15, and the fixing sleeve 15 is rota...

Embodiment 3

[0037] See Figure 1-5 , A safety and overflow-proof manhole cover, comprising a top cover 1, a support device is provided under the top cover 1, two drain holes 8 penetrate through the top cover 1, and the top of the drain hole 8 is fixed with The first block 9. The bottom end of the top cover 1 is located at the drain hole 8 and is fixedly connected to the drain pipe 2, the bottom end of the drain pipe 2 is fixedly connected to the water collecting cover 5, and the bottom end of the water collecting cover 5 is fixedly connected to the bottom cover 6, one of the two water collecting covers 5 The connecting seat 7 is fixedly connected between, and an overflow prevention mechanism is provided in the downpipe 2.

[0038] The supporting device includes a base 4, the base 4 is circular, the top of the base 4 is fixedly connected with a plurality of supporting columns 3, the top of each supporting column 3 is fixedly connected with a fixing sleeve 15, and the fixing sleeve 15 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com