A prefabricated green building splicing panel

A green building and splicing panel technology, which is applied to buildings, building components, building structures, etc., can solve the problems of cumbersome operation, reduce the production efficiency of prefabricated building splicing panels, and take a long time to make side panels and roof panels, so as to improve production. Efficiency, faster production and forming speed, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

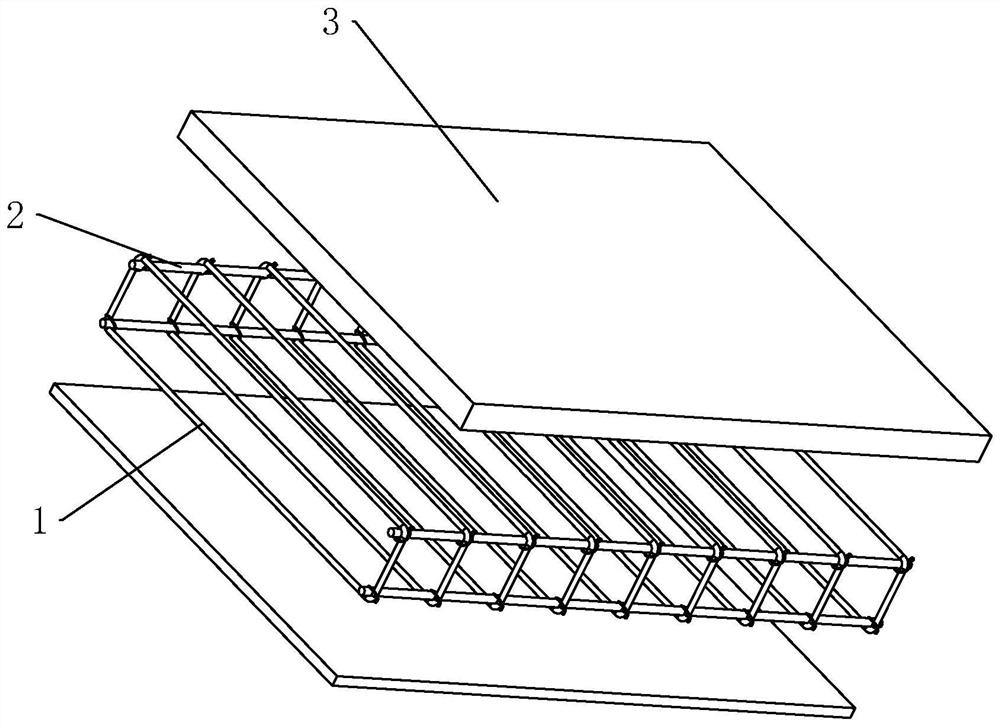

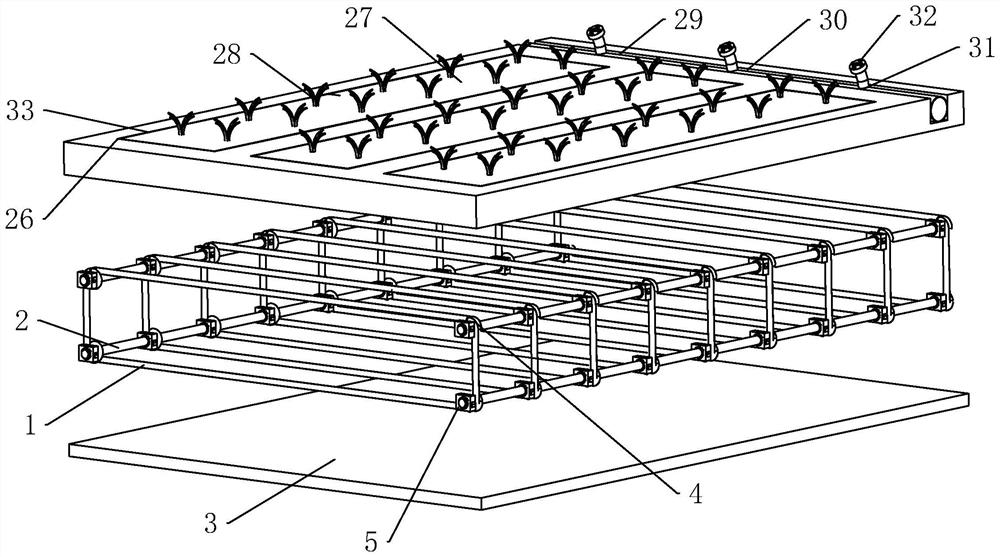

[0034] Assembly green building splicing board, reference figure 2 , Including a plurality of square steel bars, supporting the steel bars 2 and the coating plate 3. Among them, square steel bars 1 are arranged in a rectangular, and four of the square steel bars are integrated with four through holes 4 for supporting the reinforced bib 2, and the through hole 4 is arranged in a circular arrangement and is located in the four angles of square steel bars 1. Place.

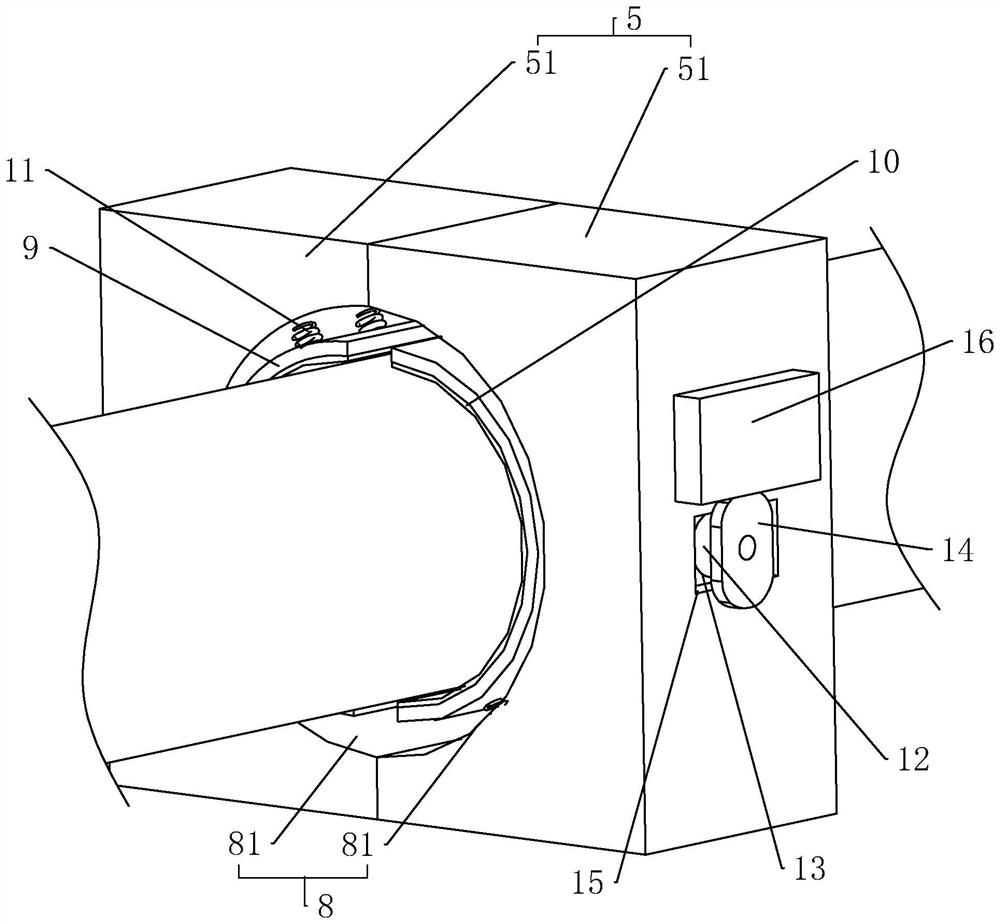

[0035] Referring to FIG. The mounting block 5 includes two identical splicing blocks 51, and the splicing block 51 is provided with a rectangular square, and the two splicing blocks 51 are fixed by the adhesive manner. The mounting block 5 is located on the side of the through hole.

[0036] Refer image 3 Both the sidewalls provided by the splicing block 51 each other have an arcuate groove 81, and when the two splicing block 51 are fixed, the two curved grooves 81 may form a cylindrical penetrating groove 8, the widewalk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com