Semiconductor refrigeration ice cream machine with fast heat dissipation and large refrigerating capacity

An ice cream machine and semiconductor technology, which is applied in the field of semiconductor refrigeration, can solve the problems of refrigeration performance at the cold end of the refrigerator, such as the effect of cooling capacity, conversion efficiency, high heat flux density at the hot end of the semiconductor refrigerator, and small thermal conductivity, etc. The effect of improving the cooling capacity, cooling coefficient and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

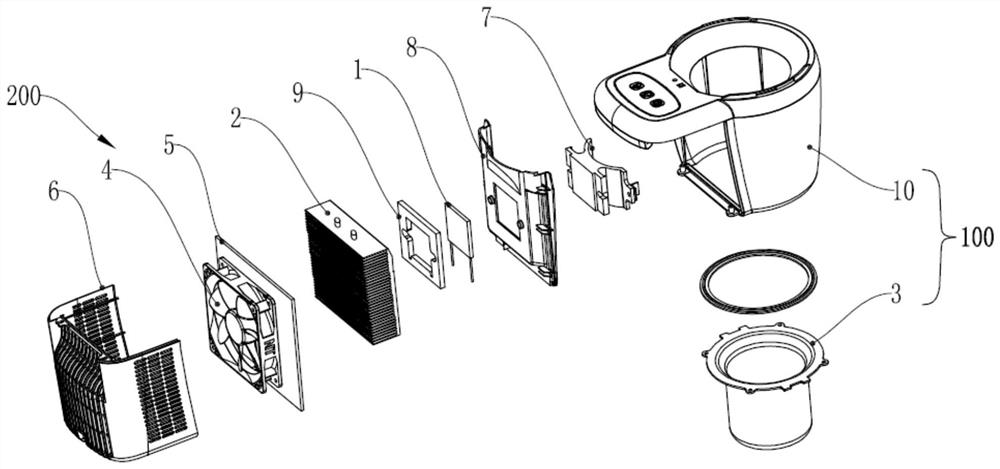

[0058] The semiconductor refrigerating ice cream machine with fast heat dissipation and large refrigerating capacity of the present embodiment, such as figure 1 As shown, it includes a main body 100 and a refrigeration mechanism 200. The refrigeration mechanism 200 is arranged inside the main body 100. It is characterized in that: the refrigeration mechanism 200 includes a semiconductor refrigerator 1 and a heat sink 2. The semiconductor refrigerator The cold end of the semiconductor refrigerator 1 is used to cool the refrigeration barrel 3 of the main body 100, and the hot end of the semiconductor refrigerator 1 is in contact with the heat dissipation substrate 21 of the heat dissipation device 2;

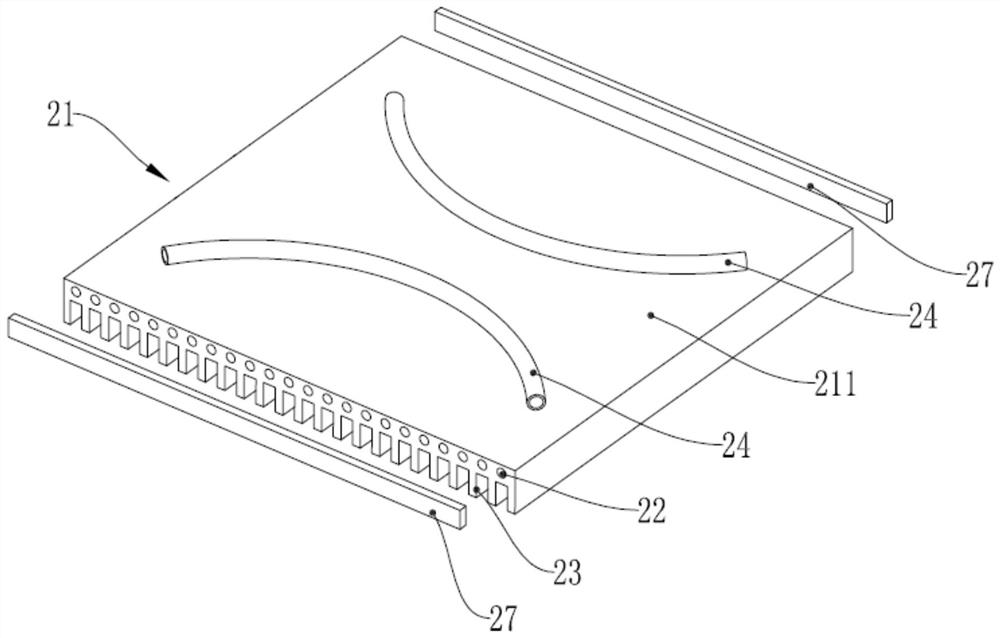

[0059] The first plate surface 211 of the heat dissipation substrate 21 that is in contact with the semiconductor refrigerator 1 is provided with a heat pipe group, and the heat pipe group passes through the joint area of the first plate surface 211 that is in contact with the se...

Embodiment 2

[0095] This embodiment carries out the following improvements on the basis of embodiment 1:

[0096] The openings of the two first heat pipes 24 of each group of first heat pipe groups respectively face the two opposite peripheries or two corners of the heat dissipation substrate 21, so as to quickly transfer the heat of the hot end of the semiconductor refrigerator 1 to the around the heat dissipation substrate 21 .

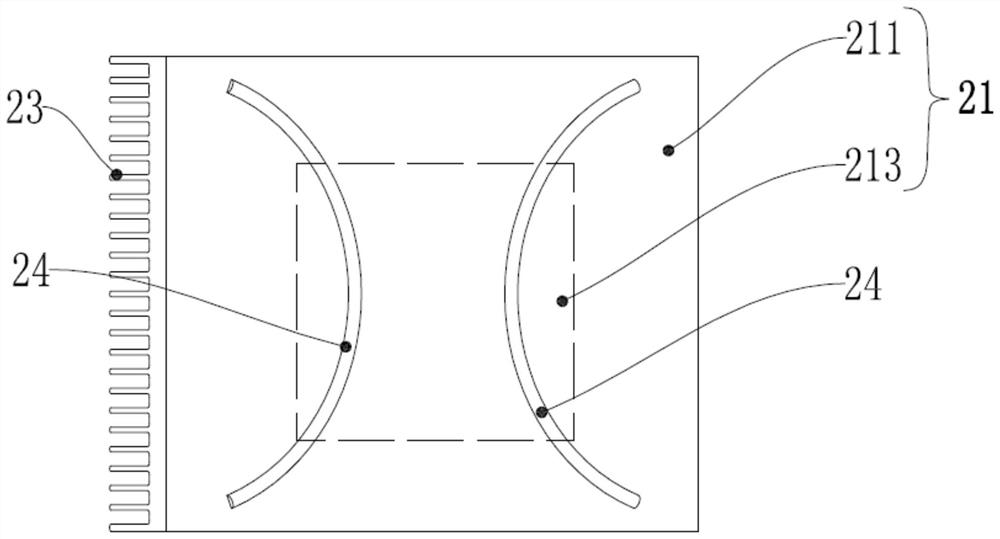

[0097] For example, if image 3 As shown, a set of first heat pipes 24 is provided, and the openings of the two first heat pipes 24 face two opposite peripheries of the heat dissipation substrate 21 respectively. Such as Figure 4 As shown, two groups of first heat pipes 24 are provided, and the openings of the two first heat pipes 24 in each group are respectively directed to two opposite peripheries of the heat dissipation substrate 21 . Such as Figure 5 As shown, a set of first heat pipes 24 is provided, and the openings of the two first heat pipes 24 ar...

Embodiment 3

[0099] This embodiment carries out the following improvements on the basis of embodiment 1:

[0100] The openings of the two first heat pipes 24 of at least one group of the first heat pipe group respectively face two opposite peripheries or two corners of the heat dissipation substrate 21, and the two first heat pipes 24 of the remaining group The openings are respectively directed towards the remaining two peripheral edges or two corners of the heat dissipation substrate 21, so that the heat of the hot end of the semiconductor refrigerator 1 can be transferred to more directions at the same time, and the heat dissipation is faster. The time is shorter.

[0101] For example, if Figure 6 As shown, there are two groups of first heat pipes 24, the openings of the two first heat pipes 24 in one group are respectively facing two opposite peripheries of the heat dissipation substrate 21, and the two first heat pipes in the other group are The openings of 24 respectively face the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com