A mine dust removal device

A technology for dust removal devices and mines, which is used in safety devices, dustproofing, mining equipment, etc., can solve the problems of difficult cleaning and one-time use, and achieve the effect of extending the replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 7 Shown:

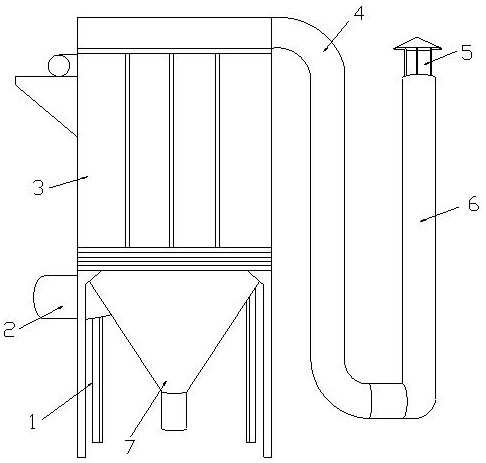

[0031] The present invention provides a mine dust removal device, the structure of which includes a support frame 1, an output pipe 2, a dust removal cabinet 3, a dredging pipe 4, a waterproof cover 5, an input bobbin 6, and a cleaning and dispersing device 7. The support frame 1 and The dust removal cabinets 3 are welded together, the cleaning and dispersing device 7 is located inside the bottom of the dust removal cabinet 3, the output pipe 2 is arranged on the left side of the dust removal cabinet 3, and the upper left end of the dredging pipe 4 is welded to the upper right end of the dust removal cabinet 3 , the waterproof cover 5 is located directly above the input tube 6, and the input tube 6 and the dredging tube 4 are socketed together.

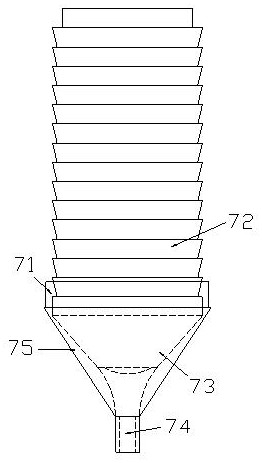

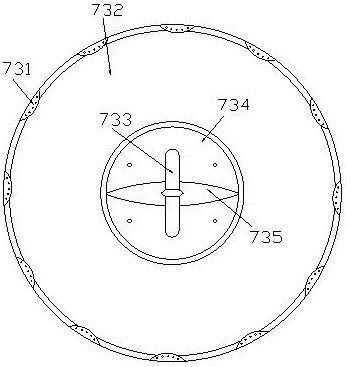

[0032] Said cleaning and filtering device 7 comprises a protruding ring 71, a dust removal filter sleeve 72, a vibration-dividing suction mechanism 73, a suction outer dischar...

Embodiment 2

[0041] as attached Figure 8 Shown:

[0042] The present invention provides a mine dust removal device. The dust removal filter sleeve 72 includes an outer filter ring 721, an inner filter screen 722, a vertical strip 723, a pressing piece 724, a ring bar 725, and a fastener 726. The outer filter ring 721 There is an inner filter 722 inside, the vertical strip 723 is fixedly connected with the fastener 726, the pressing piece 724 is arranged under the fastener 726 and is an integral structure with it, and the ring strip 725 is installed by embedding Inside the outer filter ring 721, the fastener 726 is fastened on the ring bar 725, and its downward pulling force can directly act on the ring bar 725, and the deep fitting connection between the ring bar 725 and the outer filter ring 721 can make It achieves the greatest magnitude of jitter.

[0043] Wherein, the cross-sectional diameter of the ring bar 725 is one-fifteenth of the thickness of the outer filter ring 721, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com