Fuel filter and mechanical equipment

A fuel filter and oil filtering technology, which is applied to mechanical equipment, machines/engines, liquid fuel feeders, etc., can solve the problems of untimely drainage, automatic water discharge of oil-water separators, and waste of maintenance time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

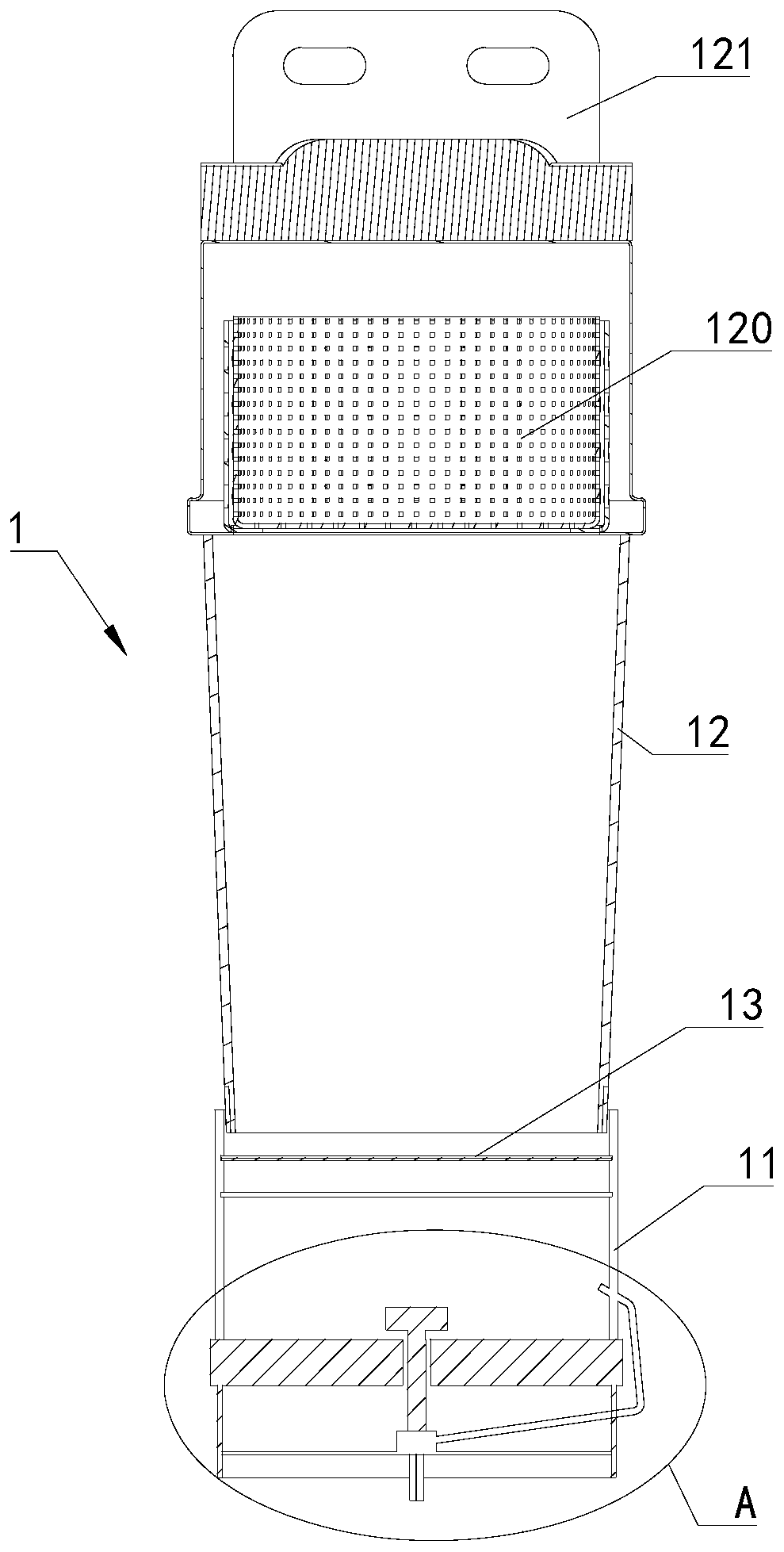

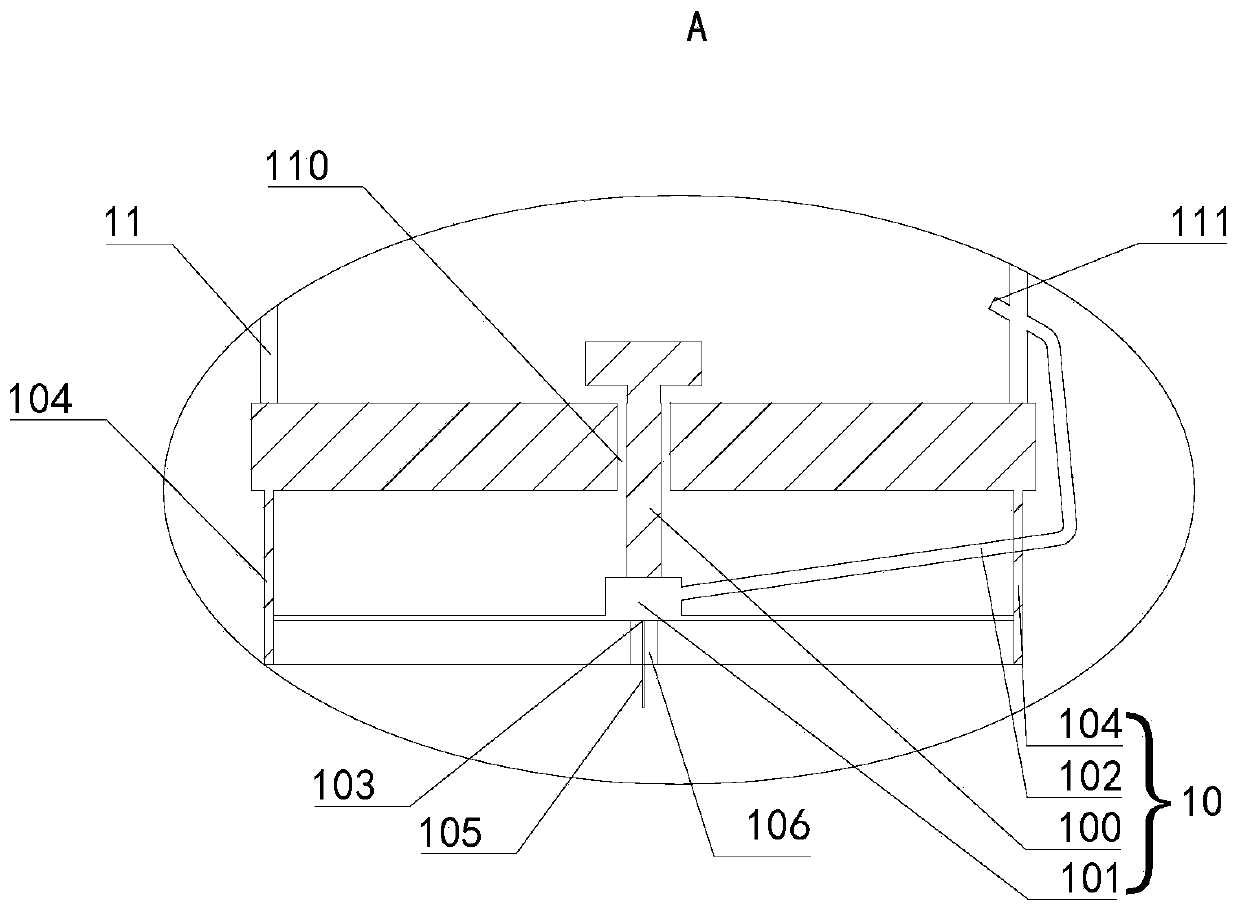

[0038] see figure 1 and figure 2 As shown, the present embodiment provides a fuel filter; figure 1 Schematic diagram of the structure of the fuel filter provided for this embodiment; figure 2 for figure 1 A partial enlarged view at A. Among them, in order to express the structure more clearly, figure 1 and figure 2 Sectional views are used.

[0039] The fuel filter provided in this embodiment is used in mechanical equipment to filter particles, water and impurities in the fuel used by mechanical equipment, and to achieve the purpose of automatically discharging the filtered water, so as to improve the fuel quality and prolong the life of the fuel. The service life of key components of mechanical equipment.

[0040] see figure 1 and figure 2 As shown, the present application provides a fuel filter 1 including a drainage mechanism 10 and a water storage body 11 .

[0041] A drainage hole 110 is provided at the bottom of the water storage body 11 , and a pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com