Rotary mechanical equipment, supercritical working medium recompression cycle power generation system and process

A technology of rotating mechanical equipment and working medium, which is applied in the direction of mechanical equipment, machines/engines, steam engine devices, etc. It can solve problems such as unreasonable speed matching, large energy density inlet and outlet pressure differences, and instability, so as to improve operational reliability and safety, compact working power, and small axial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

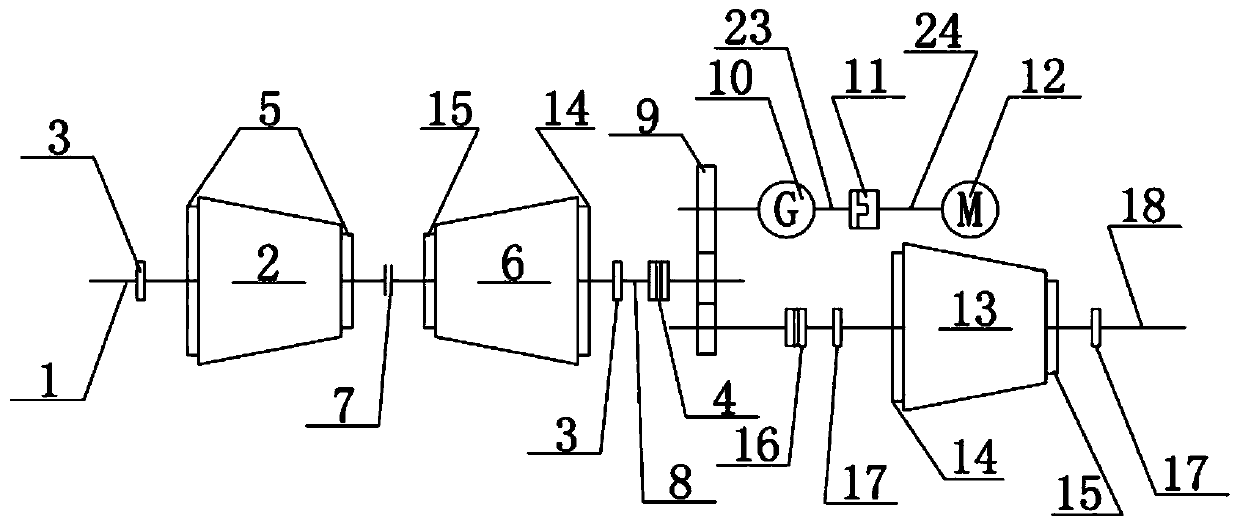

[0054] The rotating mechanical equipment provided in this embodiment is used in a supercritical working fluid recompression cycle power generation system, especially a supercritical carbon dioxide recompression cycle power generation system.

[0055] See figure 1 with figure 2 As shown, the rotating mechanical equipment provided in this embodiment includes a turbine 2 and a first compressor 6.

[0056] The drive shaft 1 of the turbine and the drive shaft 8 of the first compressor are coaxially connected to form a first rotating shaft 7, that is, the rotor of the turbine 2 and the rotor of the first compressor 6 are both connected by the first rotating shaft 7. Specifically, the high-temperature and high-pressure working medium expands in the turbine 2 to perform work, and drives the first rotating shaft 7 to rotate at a first speed, so that the drive shaft 1 of the turbine and the drive shaft 8 of the first compressor are the first compressor 6's work provides motivation. In add...

Embodiment 2

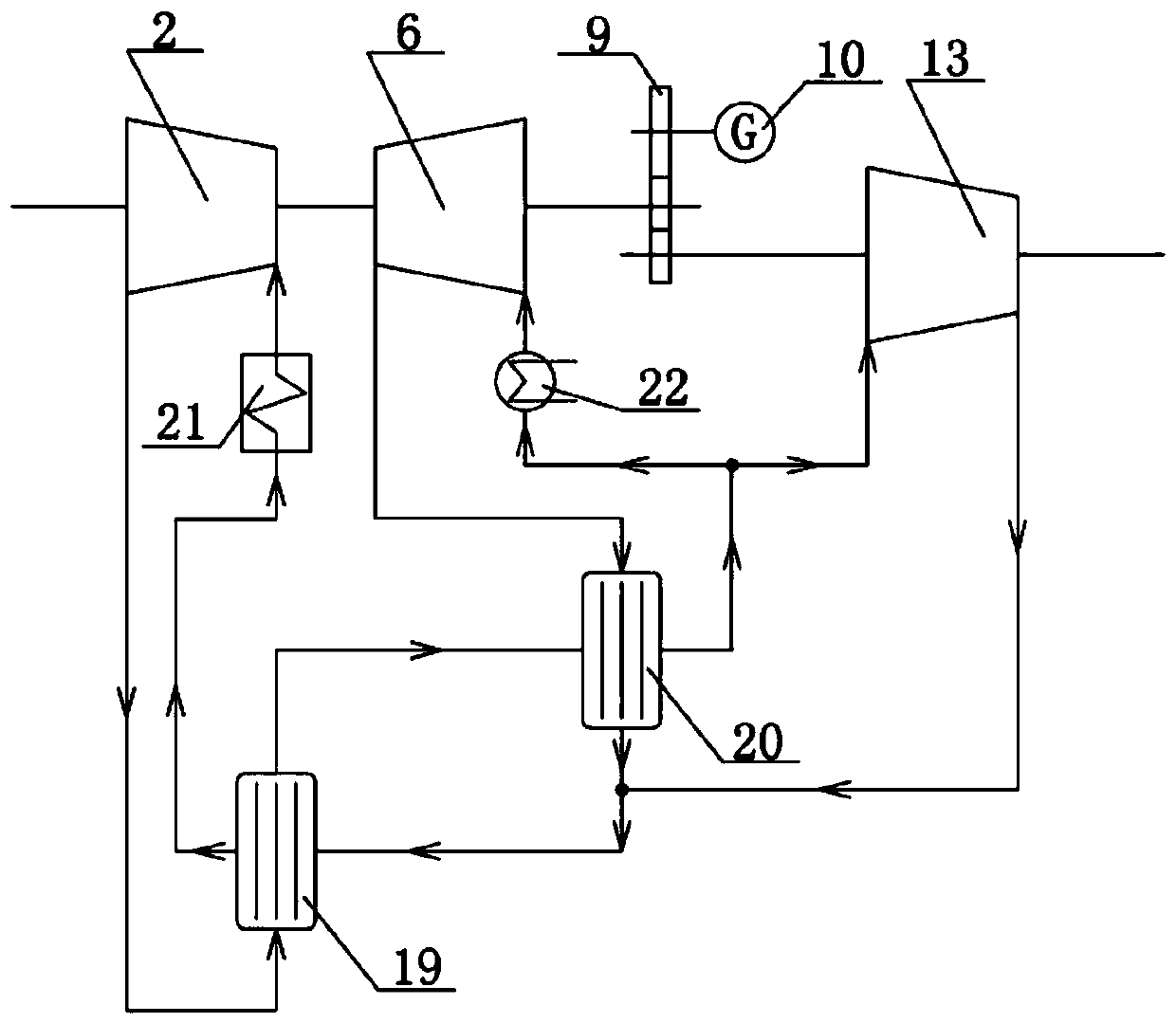

[0087] The second embodiment provides a supercritical working fluid recompression cycle power generation system. This embodiment includes the rotating mechanical equipment in the first embodiment. The technical features of the rotating mechanical equipment disclosed in the first embodiment are also applicable to this embodiment. Example 1 The technical features of the disclosed rotating machinery will not be described again.

[0088] Combine figure 1 with figure 2 As shown, the supercritical working fluid recompression cycle power generation system provided by this embodiment includes a power generation device 10, a first heat recovery device 19, a second heat recovery device 20, a heating device 21, a cooling device 22, and rotating mechanical equipment.

[0089] The first rotating shaft 7 of the rotating mechanical equipment is drivingly connected to the power generating device 10. Specifically, the first rotating shaft 7 is directly and coaxially connected to the power generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com