Moving blade design method, moving blade and steam turbine for driving air separation compressor

A design method and technology of moving blades, which are applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of low design efficiency, high design cost of moving blades, and high equipment costs of moving blades, and reduce procurement costs. Simplify the design difficulty and process, the effect of small dynamic stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

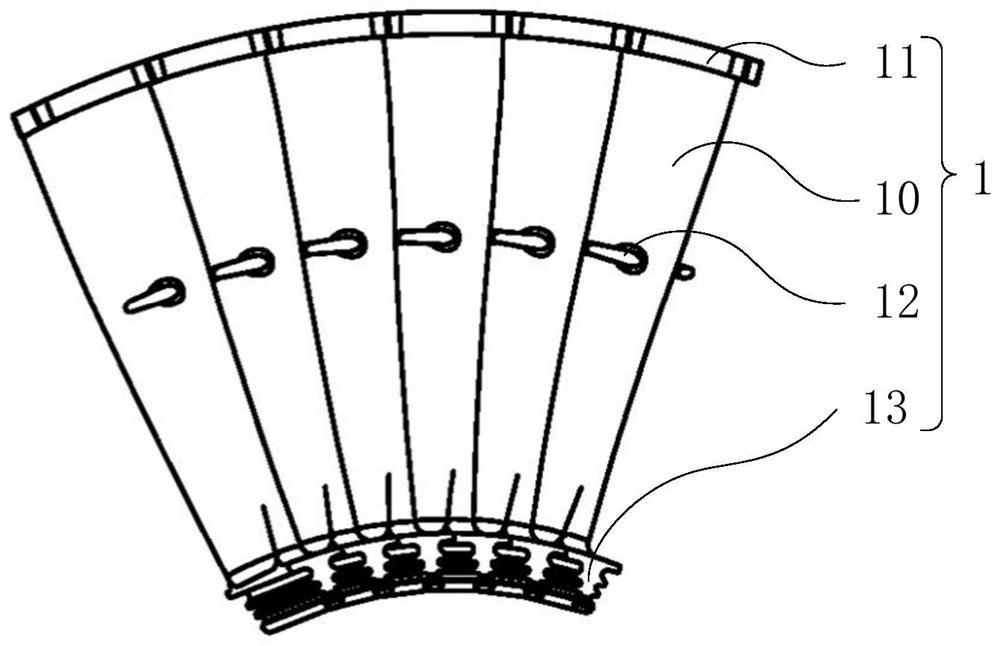

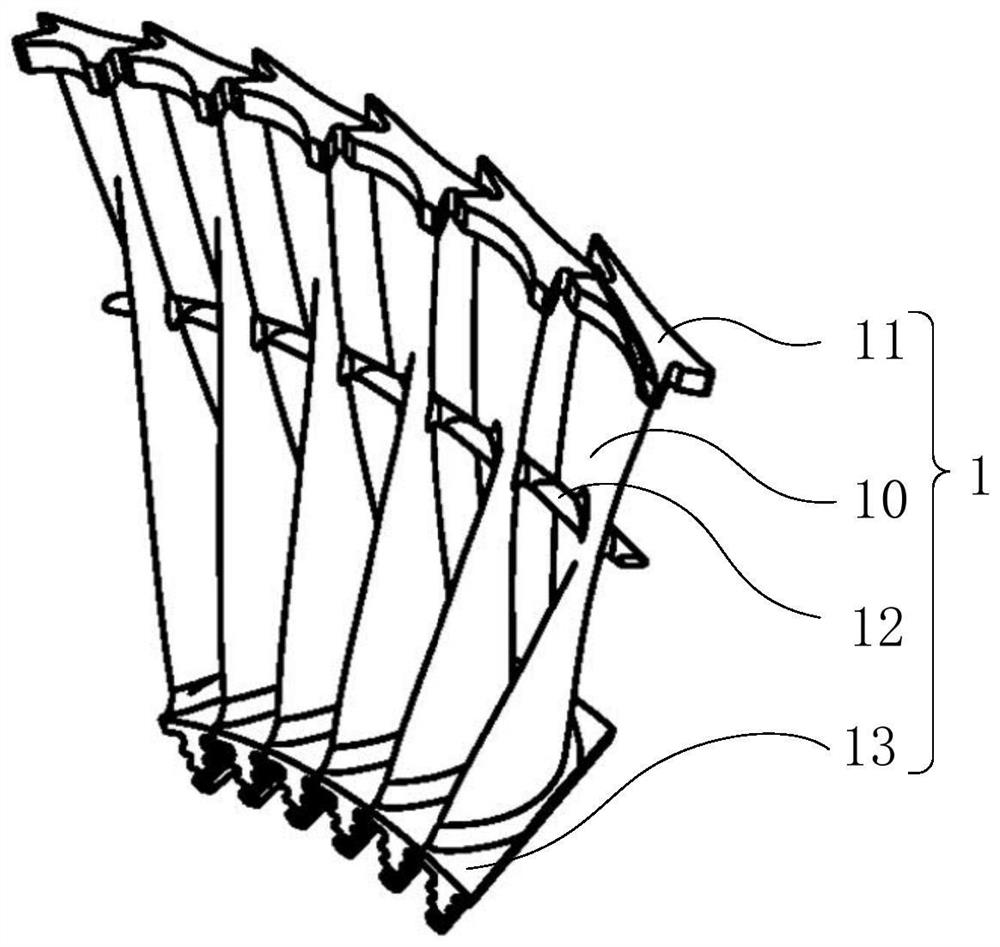

[0046] see Figure 1 to Figure 3 As shown, the embodiment of the present application provides a method for designing a moving blade including the following steps:

[0047] Step S100, the moving blade 1 is designed to include the blade root 13, the blade body 10 and the shroud 11, the blade root 13 and the shroud 11 are respectively connected to the bottom and the top of the blade body 10, and the blade body 10 and the blade root 13 are used as Basic Department;

[0048] In step S200, the disk assembly is designed to include the disk of the rotor and a plurality of moving blades 1 arranged around the disk of the rotor, the blade root 13 of each moving blade 1 is connected to the disk of the rotor, and every two adjacent The shrouds 11 of each moving blade 1 abut against each other;

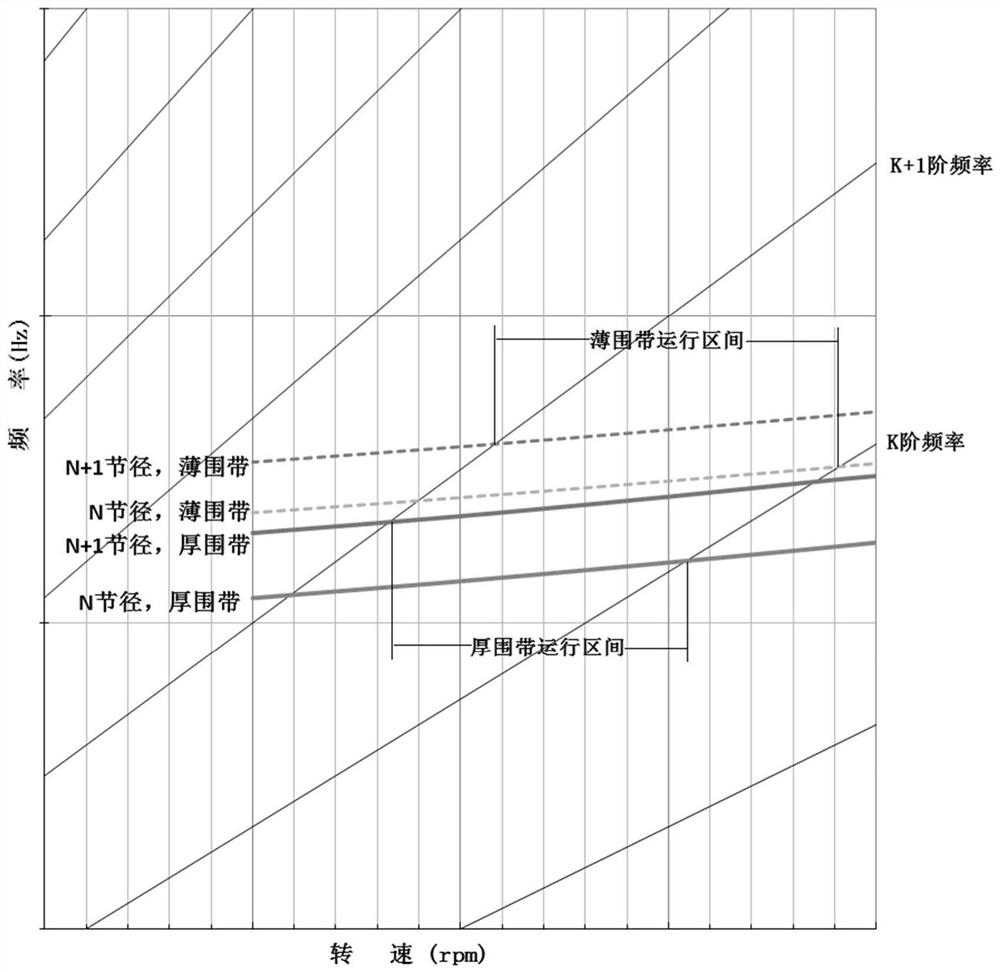

[0049] Step S300, determining the target operating interval;

[0050]Step S400, keep the basic part of the roulette assembly unchanged, adjust the parameters of the shroud 11 of the roulette ass...

Embodiment 2

[0080] see Figure 1 to Figure 3 As shown, the second embodiment provides a moving blade 1, which is designed by the design method of the moving blade in the first embodiment, and the technical features of the design method of the moving blade disclosed in the first embodiment are also applicable to this embodiment , the technical features of the disclosed rotor blade design method in Embodiment 1 will not be described repeatedly.

[0081] The moving blade 1 in this embodiment has the advantages of the design method of the moving blade in the first embodiment, and the advantages of the design method of the moving blade disclosed in the first embodiment will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com