Bidirectional output gear box

A two-way output, gear box technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem of the large size of the reducer and the inability to use intelligent four-way vehicles, etc., to achieve a small space, overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

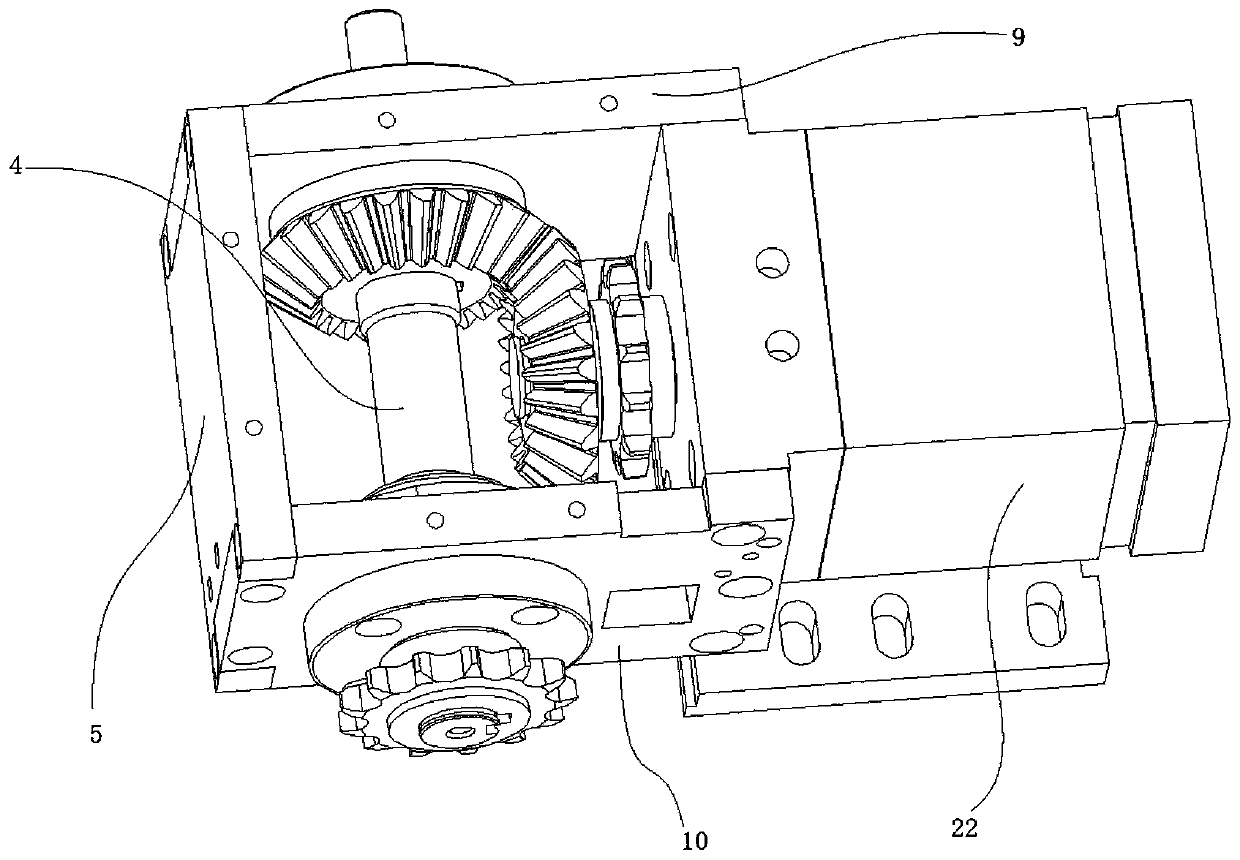

[0028] Such as figure 1 As shown, the bidirectional output gearbox in this embodiment includes a power source 22, a power output shaft 4, an assembled gearbox, a sub-roadway driving sprocket 2, a driving spiral bevel gear 3, a direction-changing spiral bevel gear 3A and a main roadway Drive sprocket 1.

[0029] In this embodiment, the driving sprocket 1 of the main roadway and the driving sprocket 2 of the sub-roadway respectively send power to the traveling wheels of the four-way vehicle through chains.

[0030] Such as figure 1 and 2 As shown, the assembled gearbox is located at the output end of the power source 22 and is connected to the casing of the power source 22 . The power source 22 is composed of a motor and a speed reducer.

[0031] The output shaft of the power source 22 is located inside the assembled gearbox, the sub-roadway driving sprocket 2 and the driving spiral bevel gear 3 are coaxially arranged on the output shaft of the power source 22, and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com