A recycled aggregate dryer with dust removal function

A technology for regenerating aggregates and dryers, applied in drying, drying cargo handling, drying solid materials, etc., can solve the problems of heat loss, low drying efficiency of dryers, etc., and achieve high drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

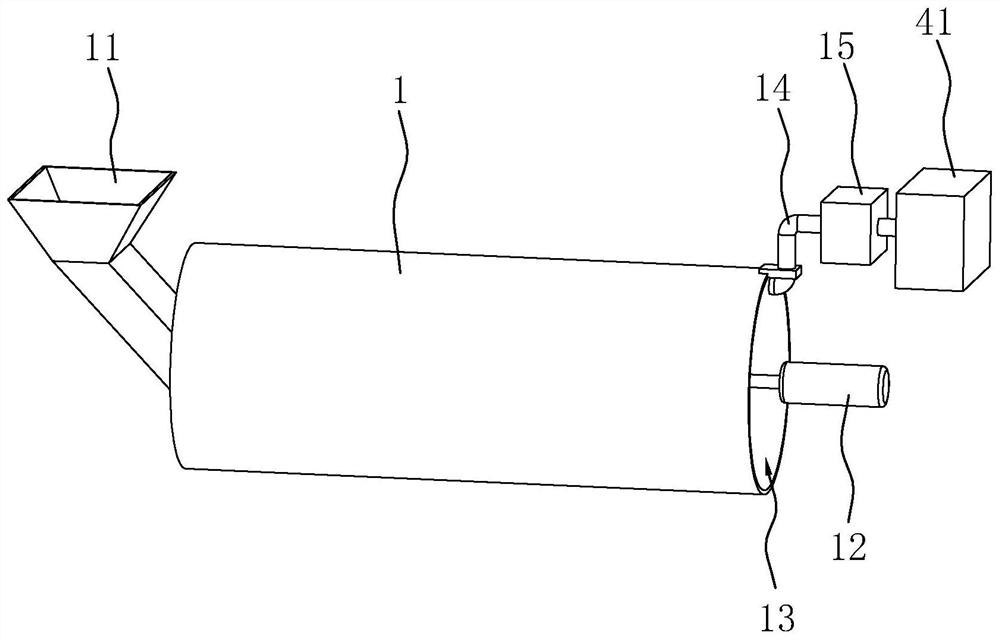

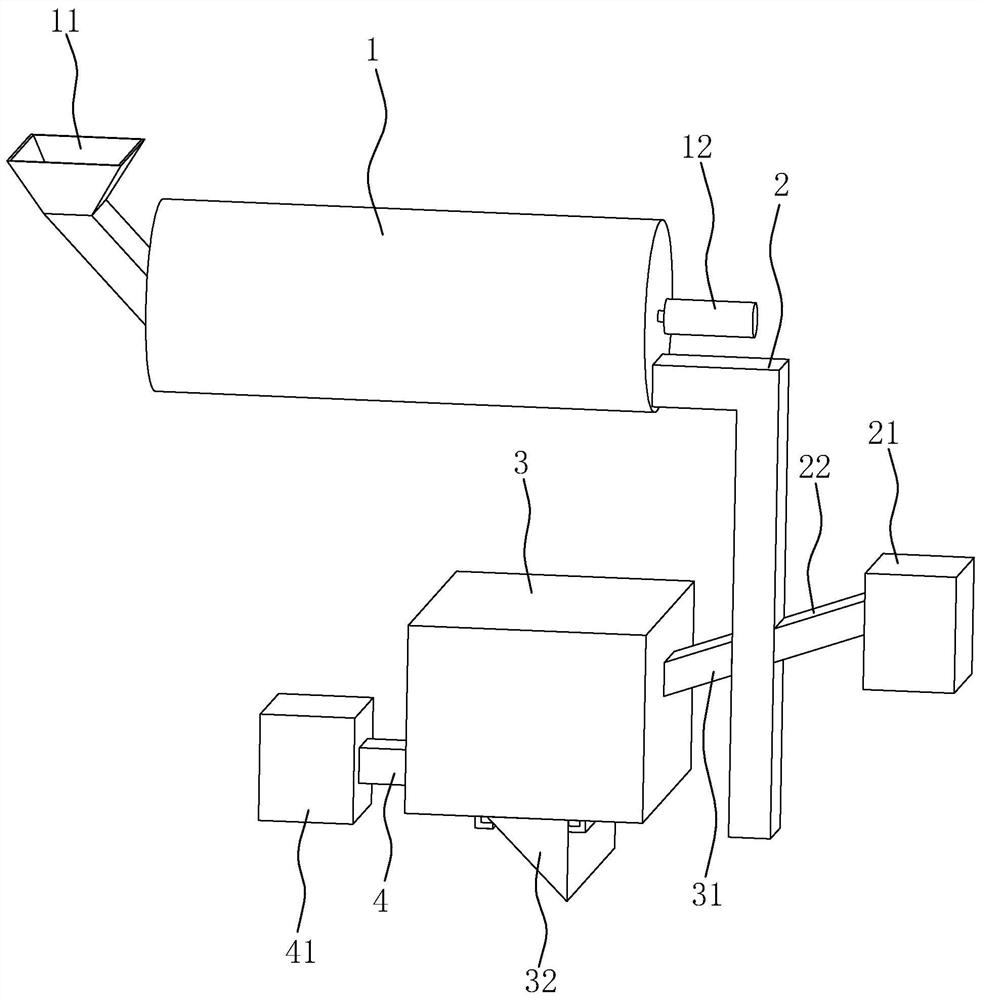

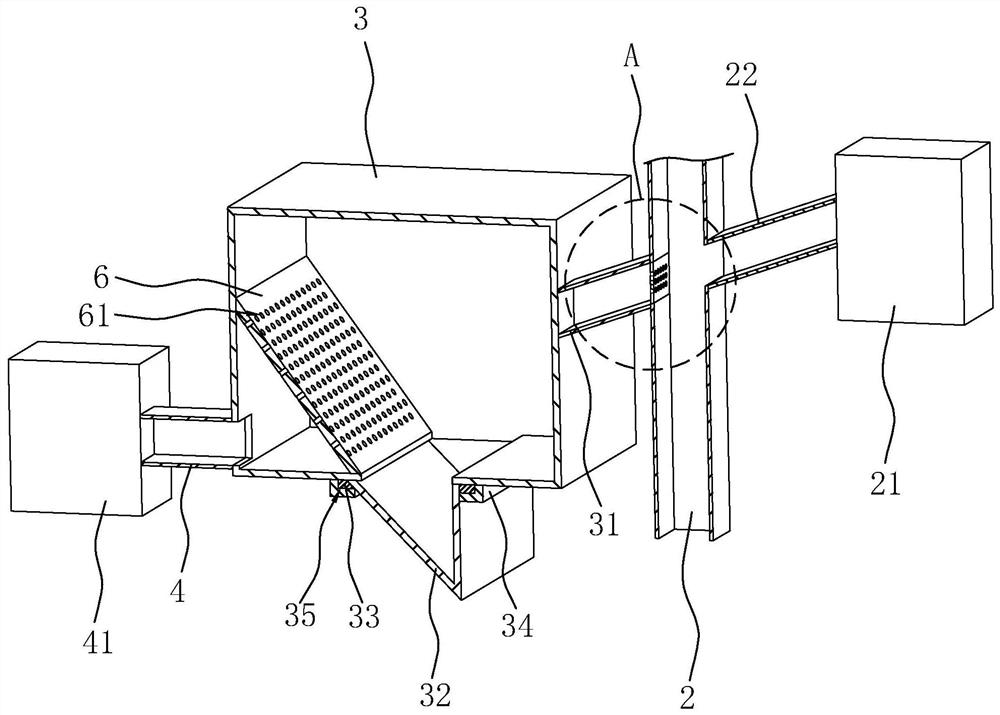

[0039] like figure 2 , is a recycled aggregate dryer with dust removal function disclosed in the present invention, comprising a drying cylinder 1, one end of the drying cylinder 1 is fixedly connected with a feeding hopper 11, and one end of the drying cylinder 1 is far away from the feeding hopper 11 A burner 12 is provided, and the burner 12 extends into the interior of the drying cylinder 1 through the end surface of the drying cylinder 1 and sprays fire toward the interior of the drying cylinder 1, so as to heat and dry the recycled aggregate inside the drying cylinder 1. One end of the drying cylinder 1 provided with a burner 12 is fixedly connected with a square discharge pipe 2 . The end of the discharge pipe 2 away from the drying cylinder 1 is bent vertically downward, and since the hot gas floats upward, the occurrence of the heat generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com