A linkage exhaust gas sampling structure for combustion exhaust gas detection

A combustion exhaust gas, linkage technology, applied in sampling, sampling device, measuring device and other directions, can solve the problems of affecting exhaust gas concentration, unfavorable accurate detection of exhaust gas, inaccurate exhaust gas concentration, etc., and achieve the effect of accurate concentration collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

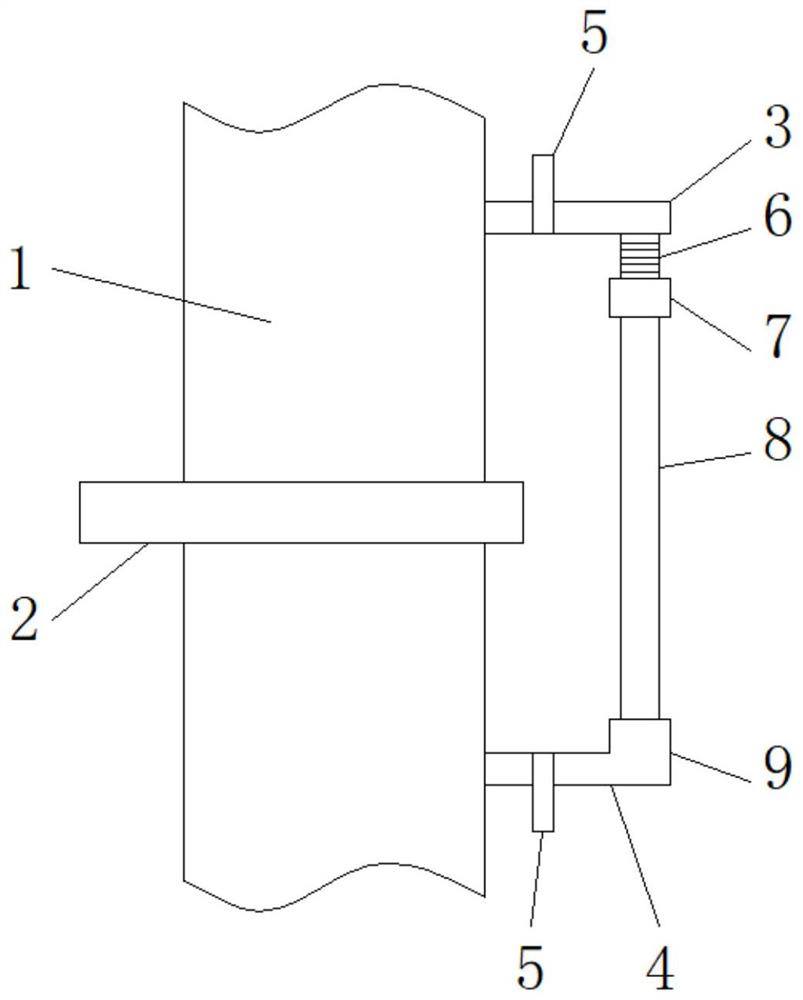

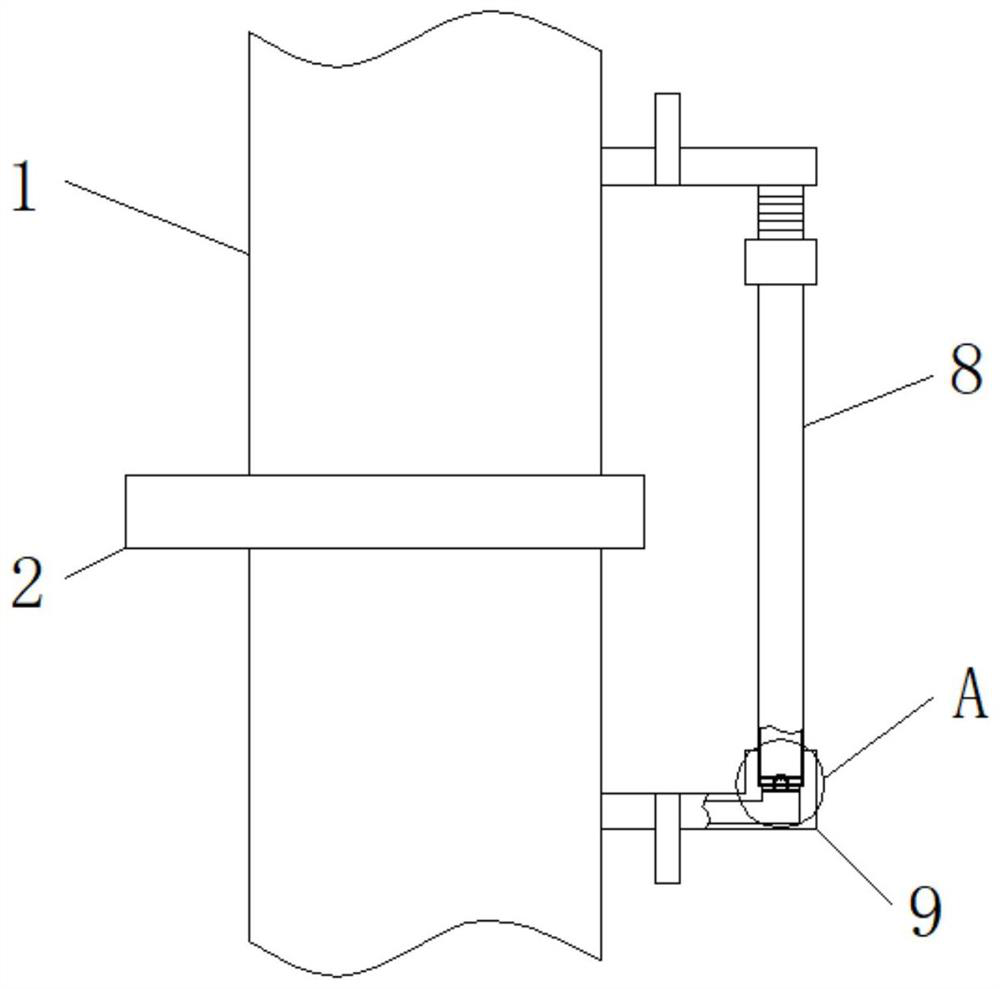

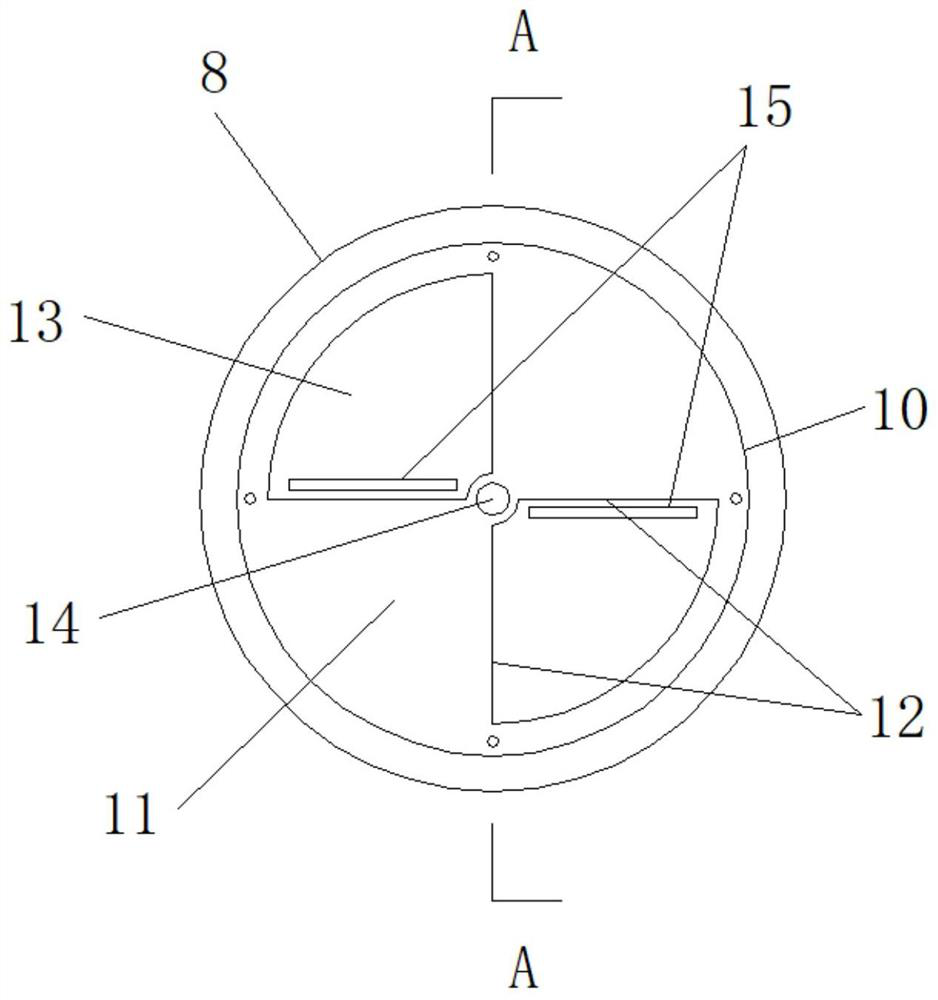

[0033] see Figure 1-11 , the present invention provides a technical solution: a linkage exhaust gas sampling structure for combustion exhaust gas detection, including an exhaust gas pipe 1, a main control valve 2, an upper shunt pipe 3, a lower shunt pipe 4, a sub-control valve 5, and a corrugated hose 6 , upper connecting sleeve 7, exhaust gas sampling pipe 8, lower connecting sleeve 9, fixing groove 10, fixing plate 11, air vent 12, sealing plate 13, connecting shaft 14, adjusting plate 15, connecting head 16, tension spring 17, sealing Cap 18, sealing ring 19, limit groove 20, support frame 21, push rod 22 and sealing gasket 23, the main control valve 2 is arranged on the waste gas pipe 1, and the waste gas pipe 1 above the main control valve 2 side is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com