Intelligent operation panel

An operation panel, intelligent technology, applied in the direction of supervision desk/panel, electrical components, etc., can solve the problems of easy misoperation and high professional requirements, achieve low production cost, reduce professional requirements, and the operation process is simple and easy to understand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

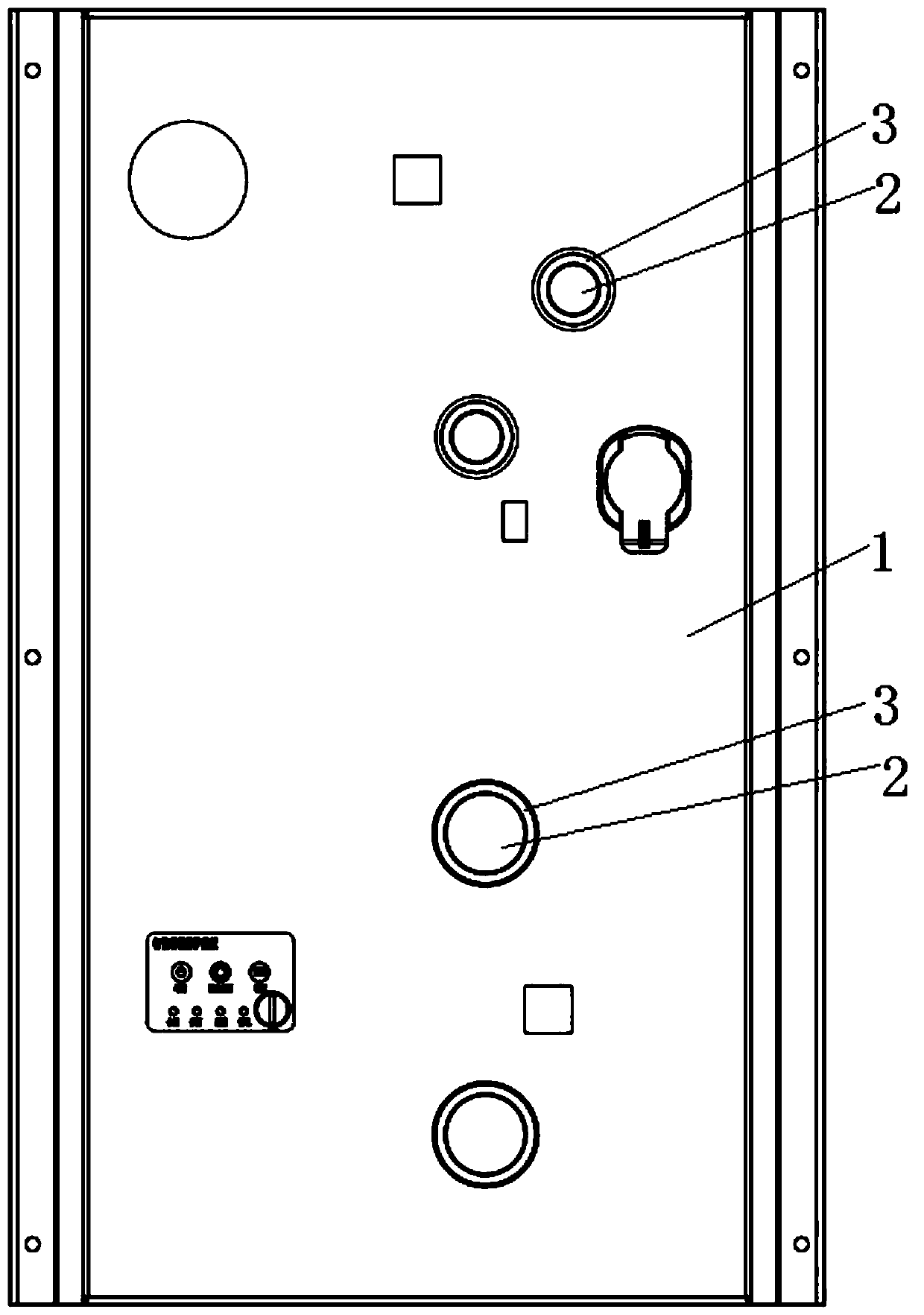

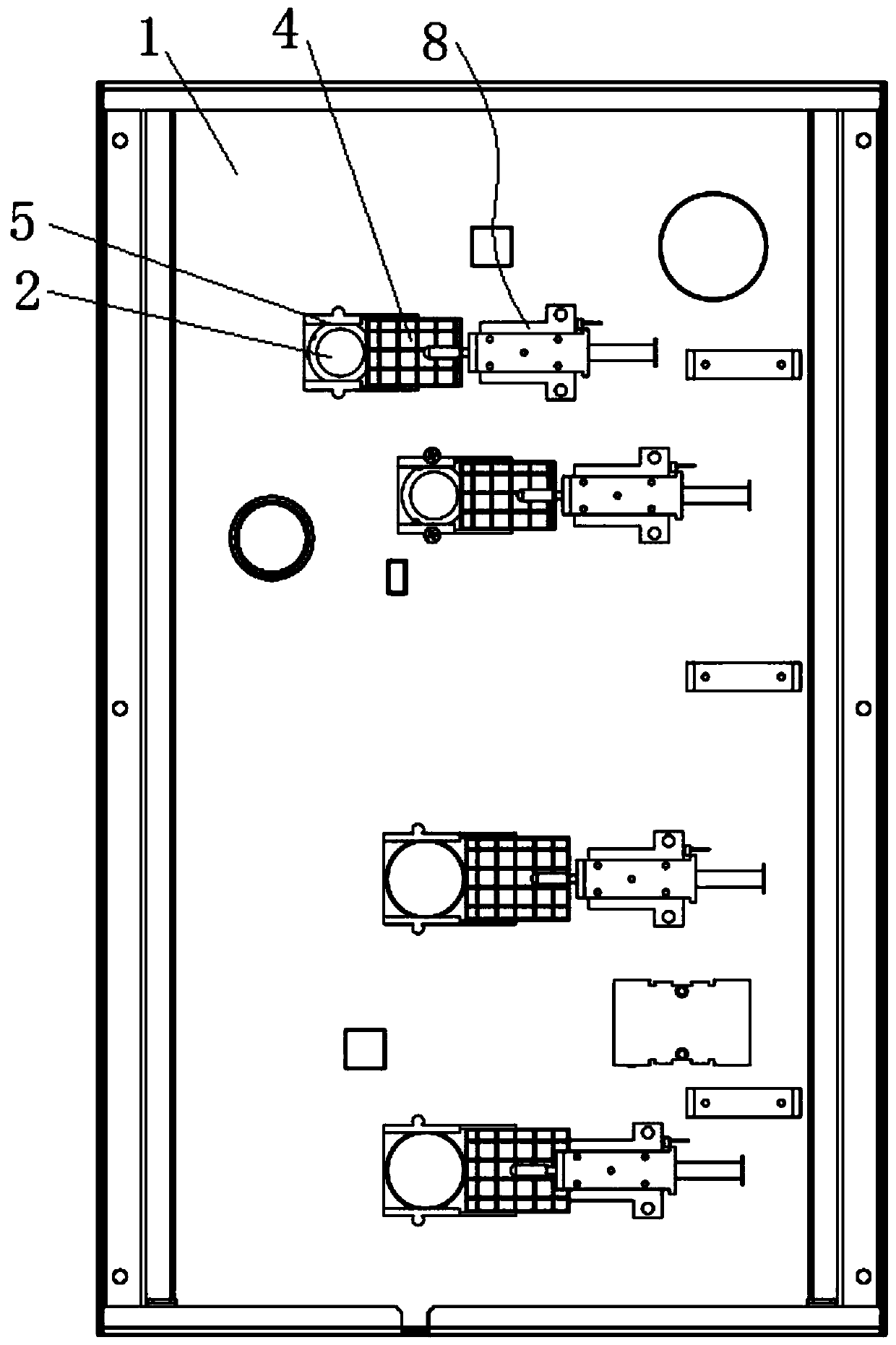

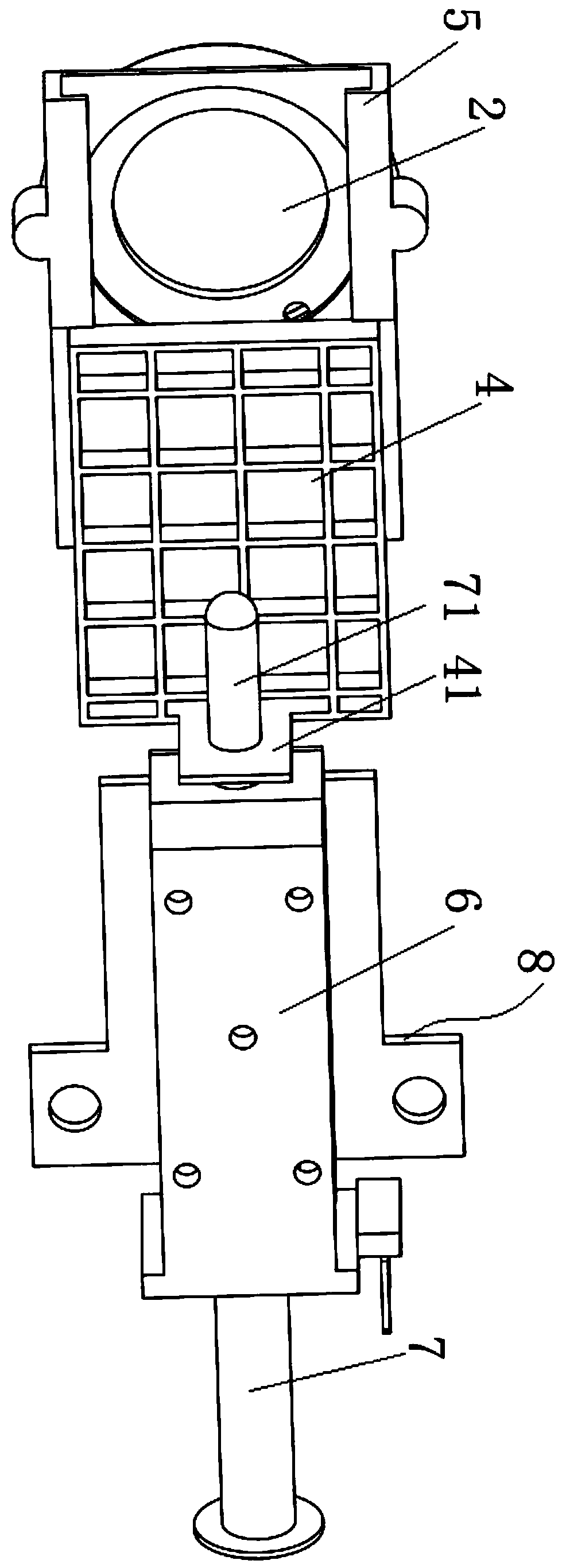

[0032] This embodiment provides an intelligent operation panel, such as figure 1 and 2 As shown, it includes an operation hole 2, an indicator light 3, a blocking mechanism and a control system.

[0033] There are four operation holes 2, which are located on the operation panel 1.

[0034] There are four indicator lights 3, which are set corresponding to the operation hole 2. The indicator lights 3 are connected with the control system, and the control system can control a plurality of the indicator lights 3 to correspond to the light-emitting instructions according to the set operation sequence. The indicator lights 3 can also be Indicate the operation direction corresponding to the operation hole 2. In this embodiment, the indicator light 3 includes an opening indication arrow for indicating the opening operation direction, and a closing indication arrow for indicating the closing operation direction (Fig. not shown in). It should be noted that the number of operating hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com