Light-weight low-voltage power supply X-ray generating device

A low-voltage power supply and generating device technology, which is applied in the field of X-ray detection, can solve the problems of increasing the volume of the fuel tank, difficulty in miniaturizing the equipment, and increasing the volume and weight of the X-ray generating device, and achieves the effect of reducing weight and improving symmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

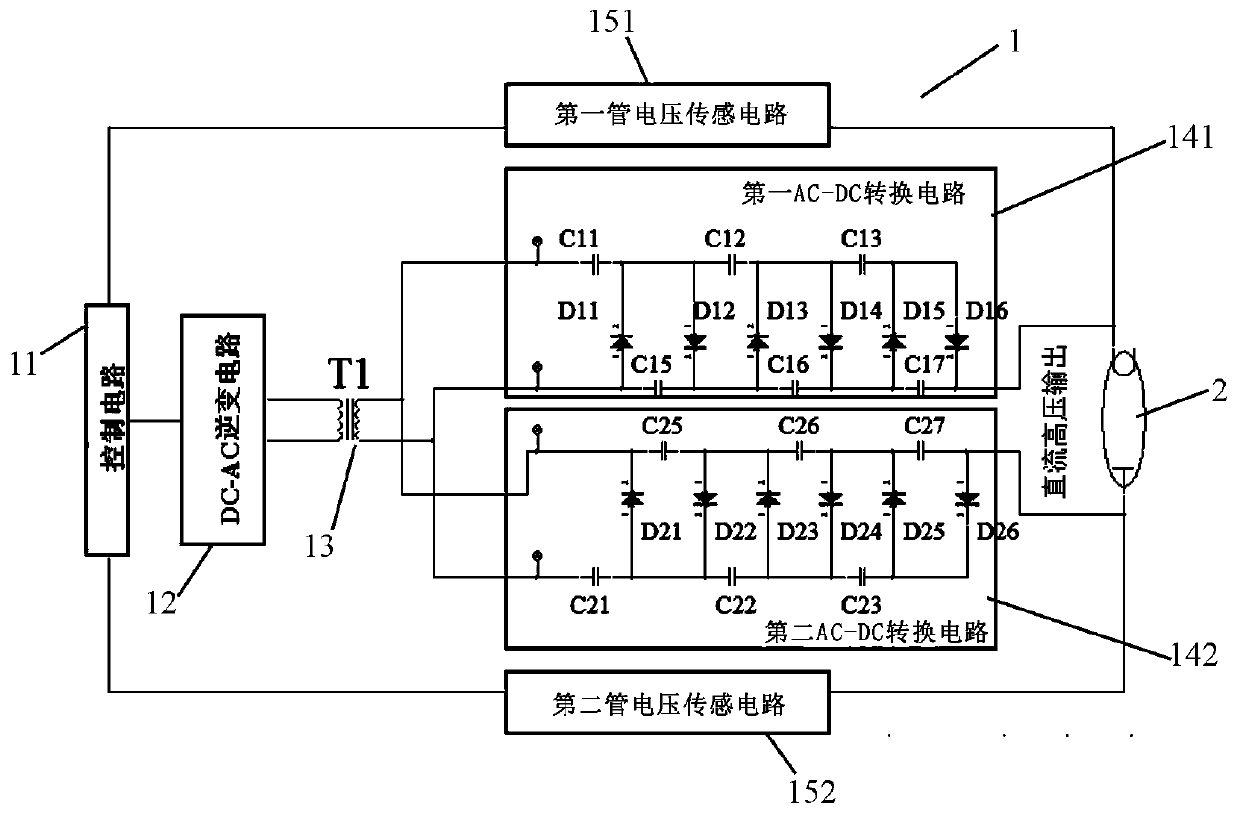

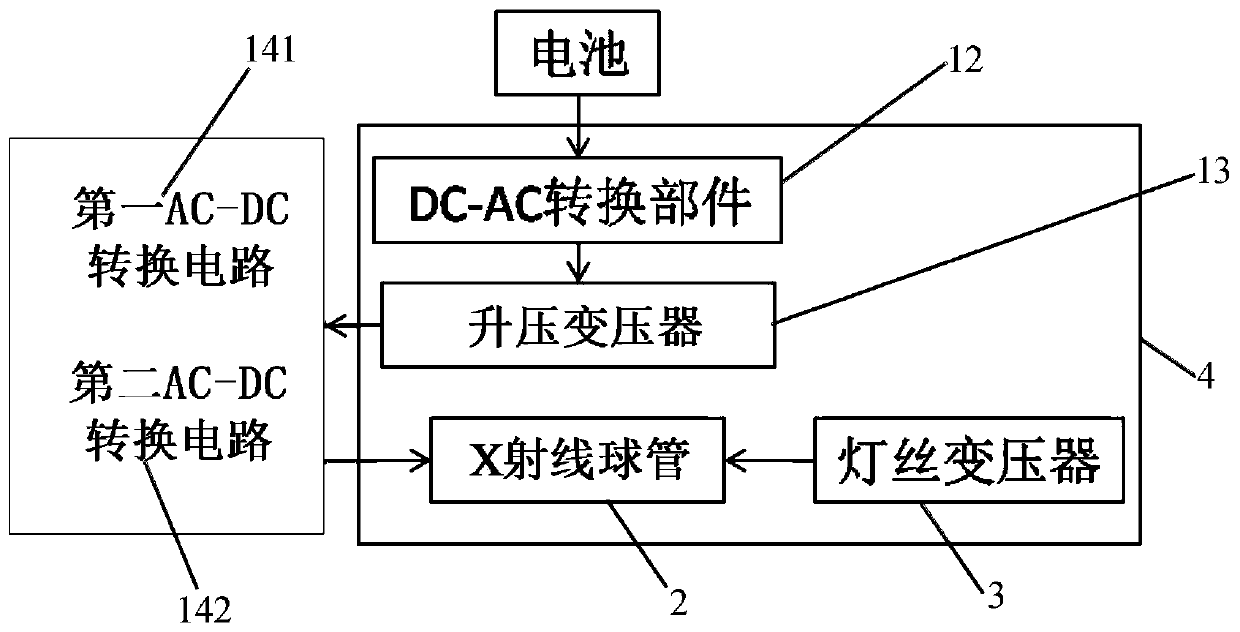

[0025] Embodiment 1: refer to figure 1 , a light-weight low-voltage power supply X-ray generating device, including a power supply circuit 1, an X-ray tube 2, a filament transformer 3 and an oil tank 4, and the power supply circuit 1 includes a control circuit 11, a DC-AC inverter circuit 12, and a step-up transformer 13. The first AC-DC conversion circuit 141 and the second AC-DC conversion circuit 142, the control circuit 11 is driven and connected to the DC-AC inverter circuit 12, and the DC-AC inverter circuit 12 is connected to an external power supply and the output is connected to a step-up transformer 13. The first AC-DC conversion circuit 141 and the second AC-DC conversion circuit 142 are circuits with mutually symmetrical functions and are connected in parallel to the output end of the step-up transformer 13; the X-ray tube 2 is connected to the first AC-DC conversion circuit. between the output terminal of the circuit 141 and the output terminal of the second AC-DC...

Embodiment 2

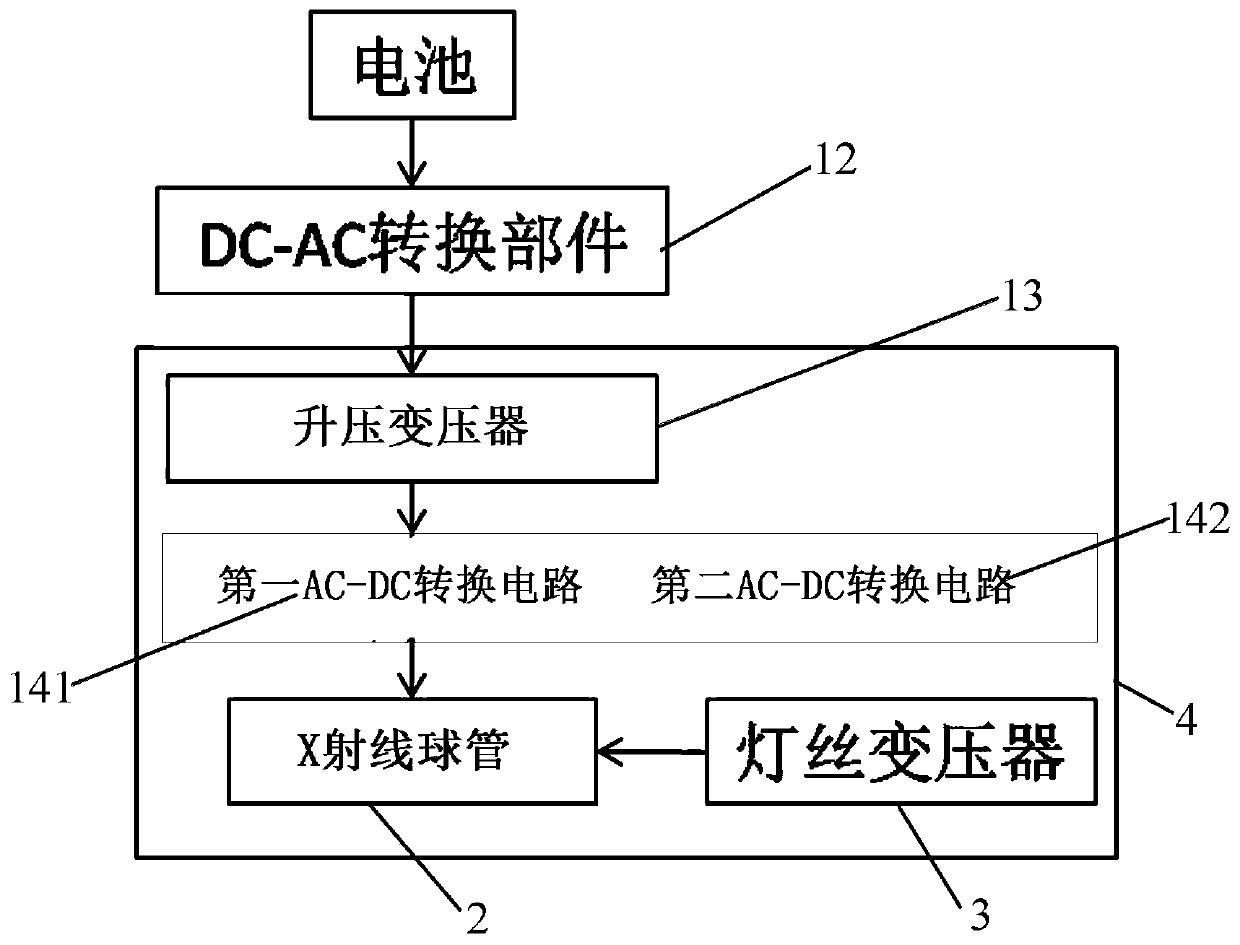

[0031] Embodiment 2, with reference to Figure 3-4 , In this embodiment, the difference from the embodiment is that: the first AC-DC conversion circuit 141 and the second AC-DC conversion circuit 142 are arranged in the fuel tank 4 . The first AC-DC conversion circuit 141 and the second AC-DC conversion circuit 142 are arranged in the oil tank 4 and are insulated and radiated by the oil in the oil tank 4. Specifically, the first AC-DC conversion circuit 141 and the second AC - The DC conversion circuit 142 is arranged separately and symmetrically in the oil tank 4, preferably, the first AC-DC conversion circuit 141 and the second AC-DC conversion circuit 142 can be respectively arranged on both sides of the step-up transformer 13 located in the middle of the oil tank 4 , so that the arrangement of components in the fuel tank 4 is more compact, the overall volume of the device is reduced, and the distance between the first AC-DC conversion circuit 141 and the second AC-DC conve...

Embodiment 3

[0032] Embodiment 3, with reference to Figure 5 , this embodiment is based on Embodiment 2, and the DC-AC inverter circuit 12 is connected to the oil in the oil tank 4 through the heat conduction mechanism 7 . Specifically, the heat conduction mechanism 7 includes a heat conduction seat 71 and a plurality of cooling fins 72 integrally connected with the heat conduction seat 71, the plurality of heat dissipation fins 72 are arranged in the fuel tank 4, the heat conduction seat 72 is arranged outside the fuel tank 4, and the DC-AC inverter circuit 12 is fixed Set on the heat conduction seat 72 . The DC-AC inverter circuit 12 is connected to the oil in the oil tank 4 through the heat conduction mechanism 7, and the oil in the oil tank 4 can be used to dissipate heat from the DC-AC inverter circuit 12, thereby eliminating the need for the DC-AC inverter circuit 12 The unique heat dissipation mechanism further reduces the volume and weight of the device, achieving a lightweight e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com