Environmental-friendly picking device for tea leaves

An environmental protection, tea technology, applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of unsuitable height, tea picking, large equipment, etc., to achieve easy operation, reduce the use of diesel oil, etc., and reduce pollutants. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

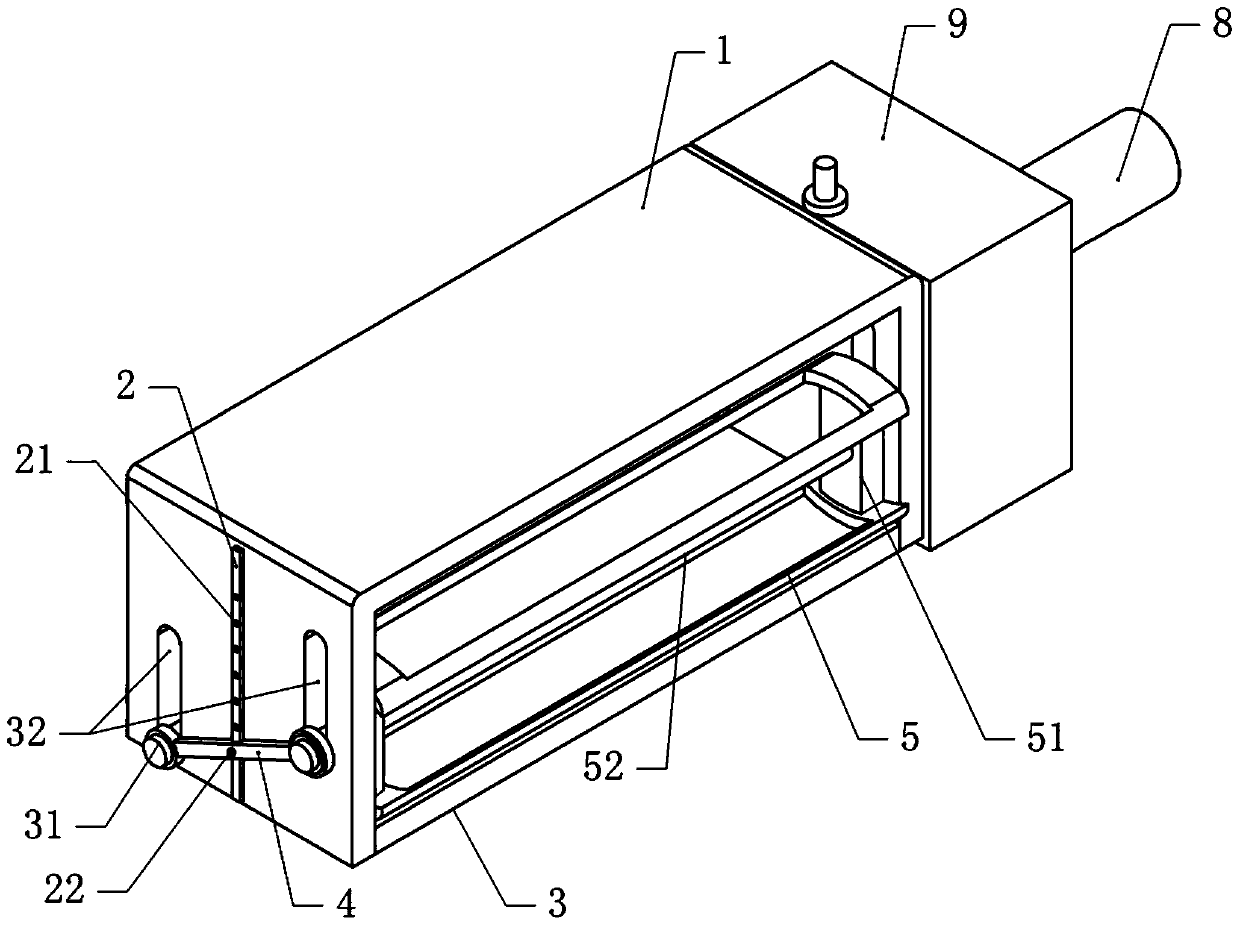

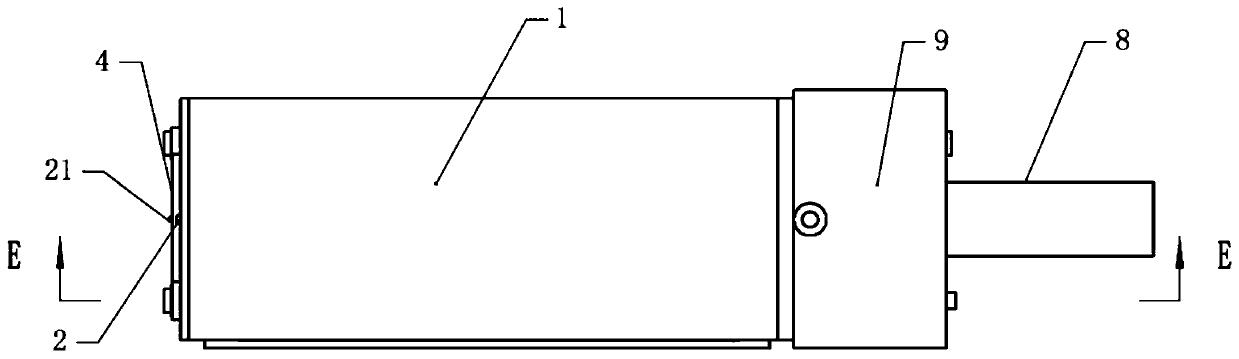

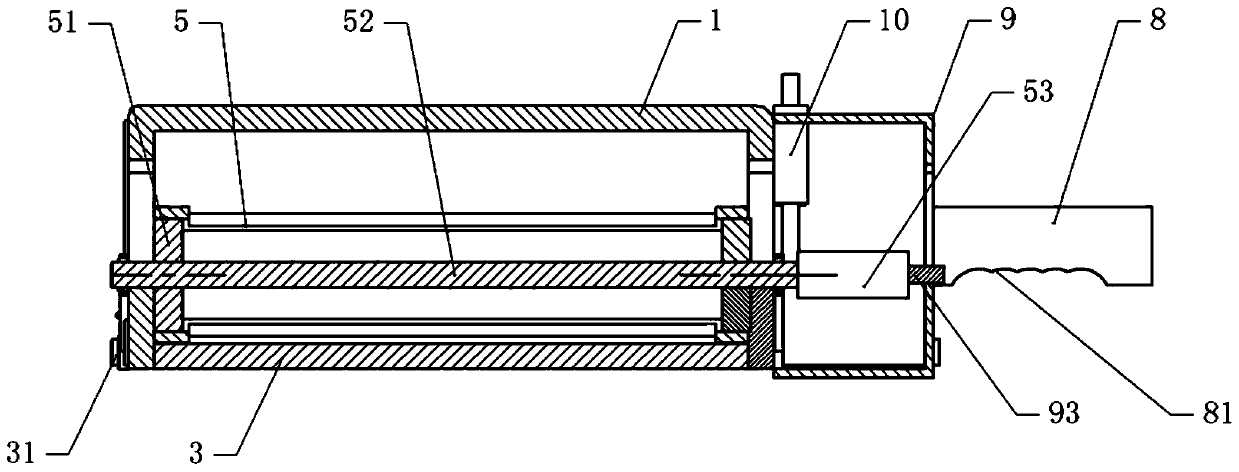

[0039] Basic as attached figure 1 As shown, a tea environmental protection picking device includes a main frame 1 and a sub-frame 9 bolted on the right side of the main frame 1, and the bottom and front and back of the main frame 1 have openings. One side of the main frame 1 has two sliding holes 32, combined with the attached Figure 4 As shown, the other side of the main frame 1 is provided with two auxiliary sliding holes 92, and the lower part of the main frame 1 is vertically slidably connected with a baffle plate 3, and the rear side of the baffle plate 3 is welded with a sliding shaft 31, and the sliding shaft 31 The two ends of the cylinder are respectively located in the sliding hole 32 and the auxiliary sliding hole 92. The right side bolt in front of the main frame 1 is fixed with a cylinder, and the output shaft of the cylinder is fixedly connected with the baffle plate 3 bolts (not shown in the figure). The shaft 31 is supported so that the baffle 3 is horizontal...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is that, as attached Figure 5 , attached Image 6 , attached Figure 7 And attached Figure 8 As shown, the coaxial bolt on the main shaft 52 is fixed with the main gear 54, the main gear 54 meshes with the secondary gear 55 which is rotationally connected with the second connecting plate 42, and the gear ratio of the main gear 54 and the secondary gear 55 is 3:1~5:1 , The gear ratio of the main gear 54 and the slave gear 55 in this embodiment is 3:1. There is an air channel 6 in the main shaft 52, and some air holes 61 communicating with the air channel 6 are arranged on the main shaft 52. The main shaft 52 is rotatably connected with a mounting block 7 that is vertically slidably connected with the main frame 1, and there is a space in the mounting block 7. A cavity 73 , and a through hole 62 communicating with the cavity 73 is opened on the main shaft 52 .

[0050] The first wedge 56 is welded on the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com