A method for measuring the lateral distribution of surface temperature of hot-rolled intermediate slab

A technology of lateral distribution and surface temperature, applied in metal rolling, length measuring device, metal rolling, etc., can solve the problem of uneven surface temperature distribution of intermediate billet and strip steel, inability to measure lateral distribution of intermediate billet temperature at the exit of roughing mill, Unable to reflect temperature distribution characteristics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

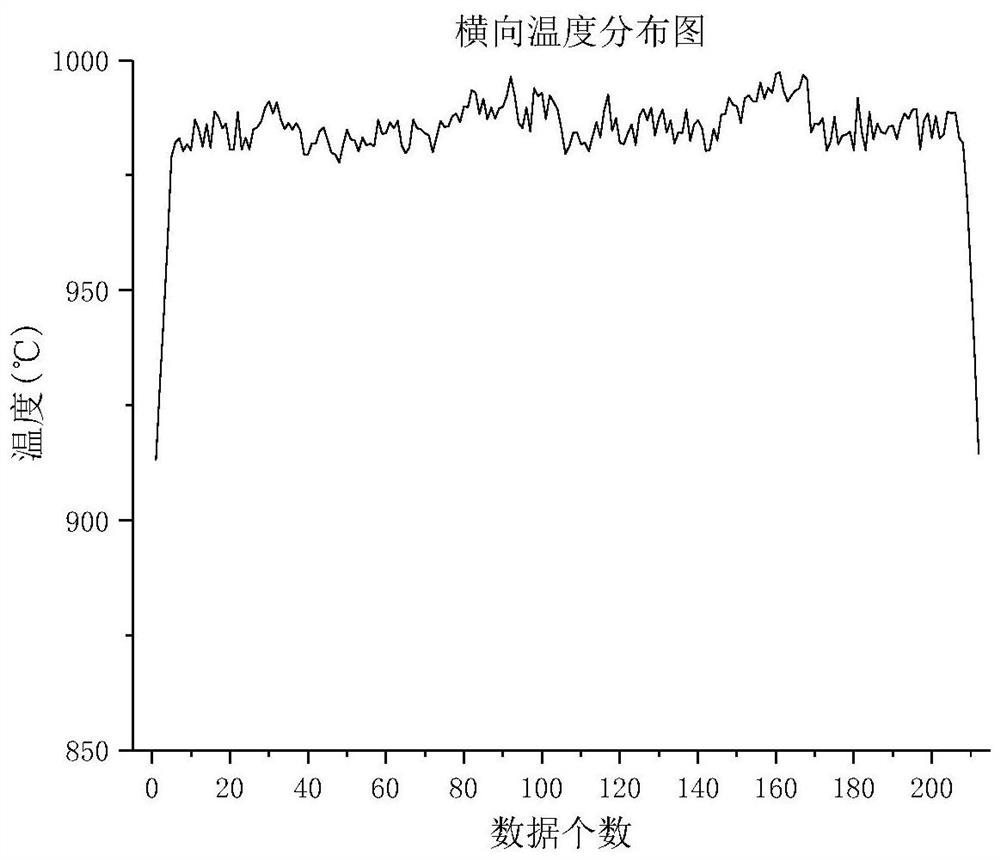

[0027] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

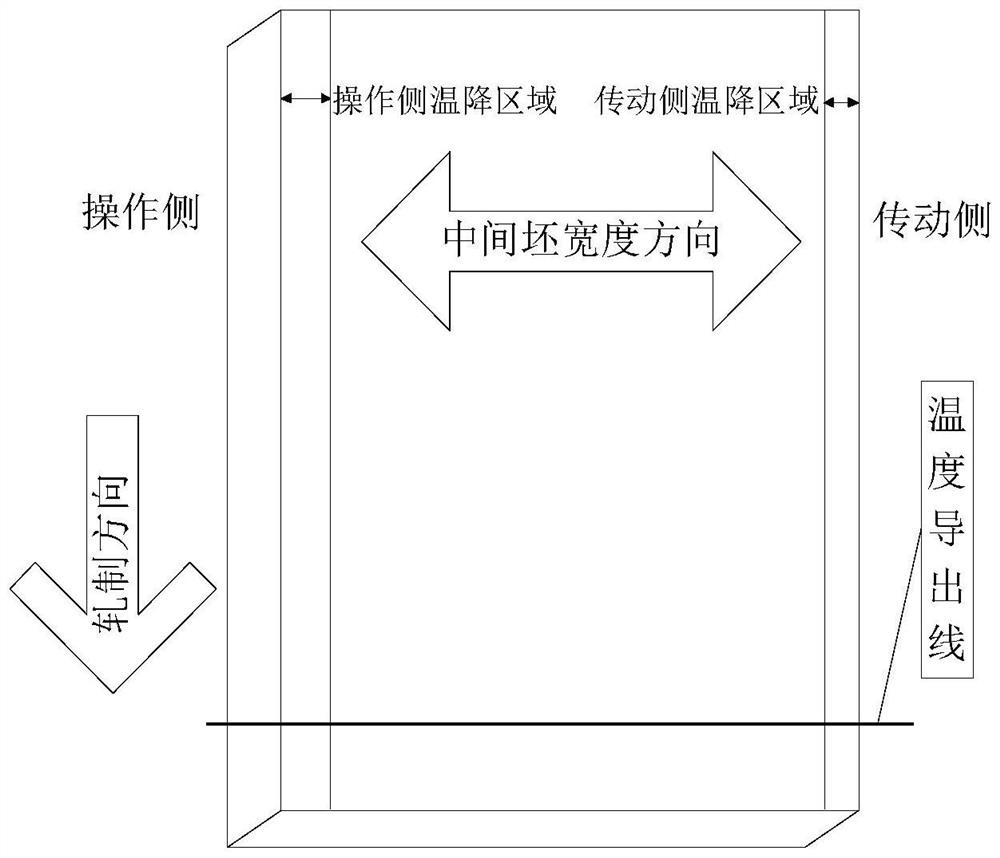

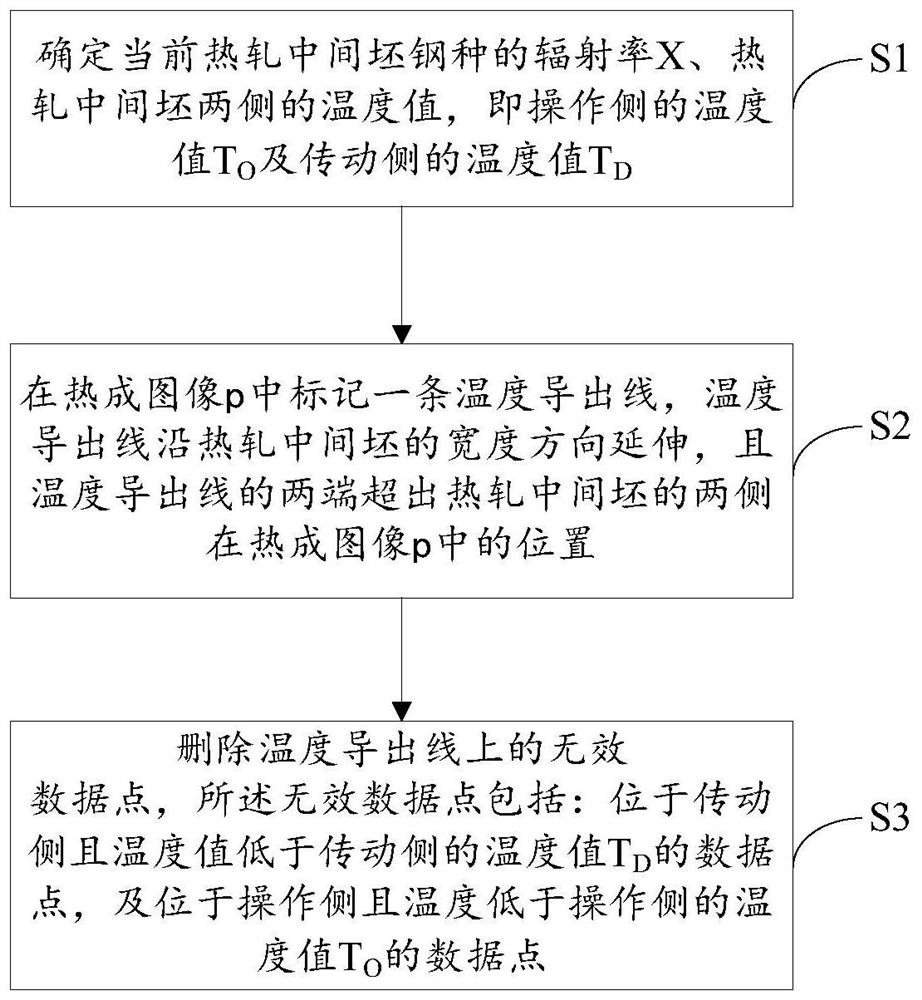

[0028] figure 2 The flow chart of the method for accurately measuring the lateral distribution of the surface temperature of the hot-rolled intermediate slab provided by the embodiment of the present invention, the method specifically includes the following steps:

[0029] a. Obtain the actual temperature value T of the surface center of the hot-rolled intermediate billet at present, and obtain it through the effective thermometer configured on the production site, which is the actual temperature value of the upper surface center of the hot-rolled intermediate billet or the actual temperature of the lower surface center of the hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com