Glass processing table

A technology for processing tables and glass, which is applied in metal processing equipment, manufacturing tools, and machine tools suitable for grinding the edge of workpieces, etc. It can solve problems such as uneven force on edging, broken glass, glass vibration, etc., to avoid impact force Too large to reduce the degree of splashing and avoid the effect of uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

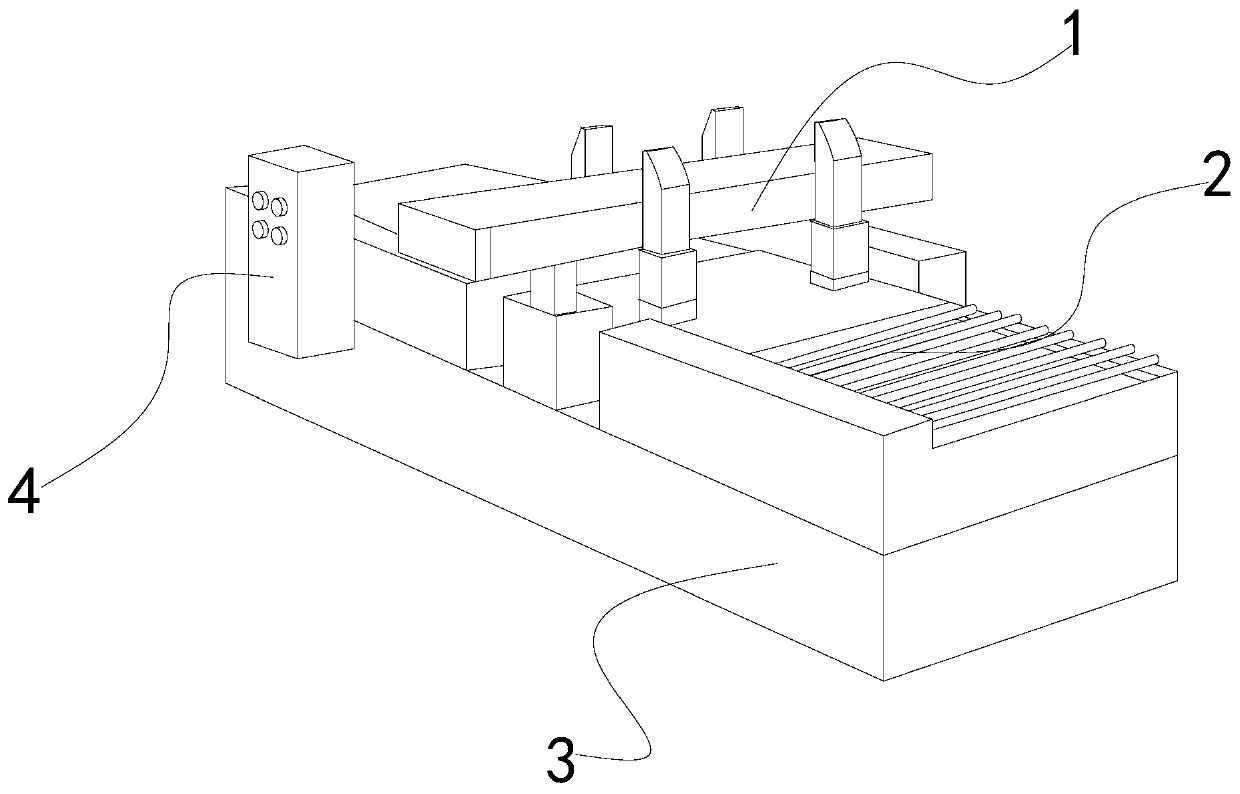

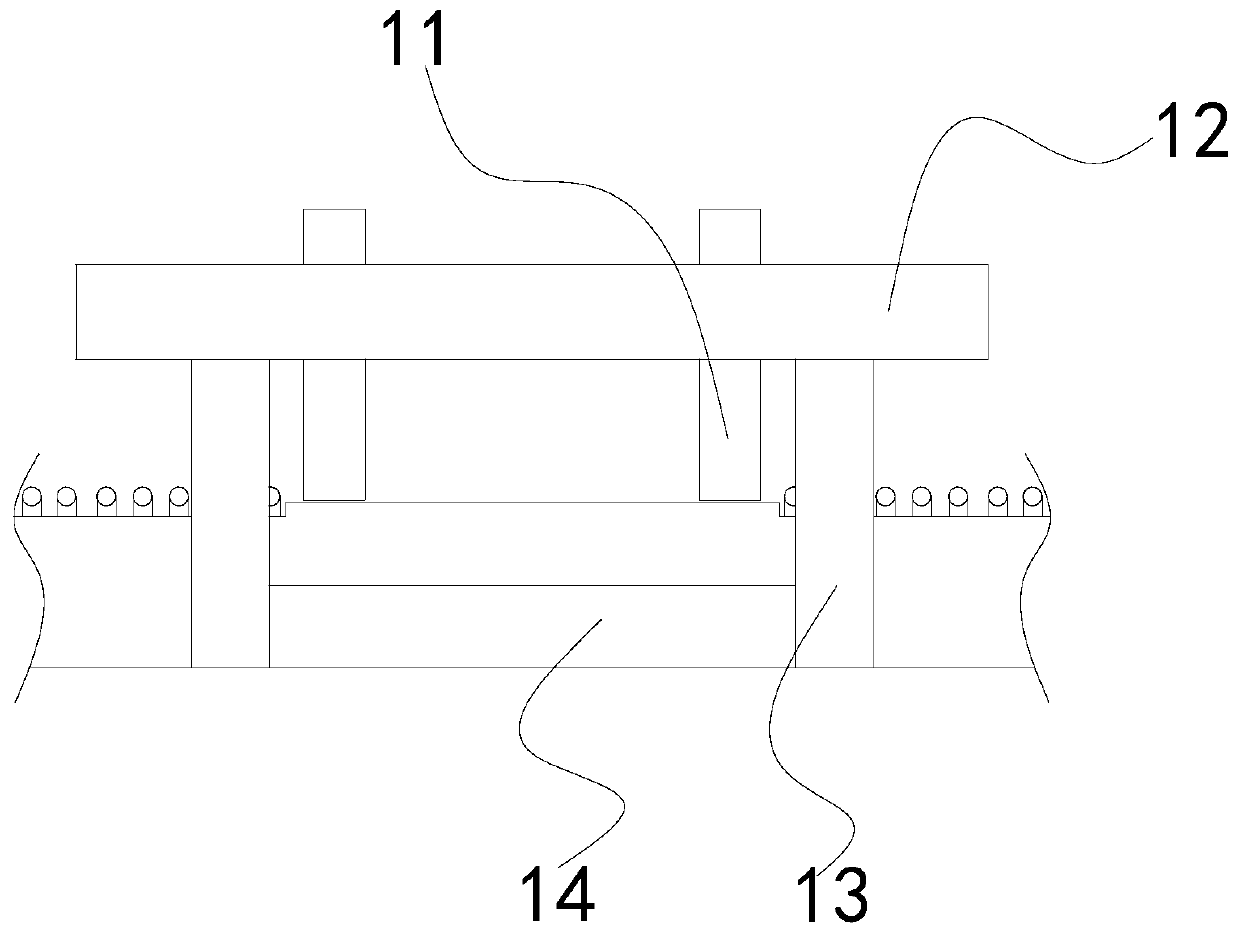

[0025] like Figure 1-Figure 6 Shown:

[0026] The present invention is a kind of glass processing table, its structure comprises processing device 1, slide shaft 2, processing table 3, control box 4, the lower end of described processing device 1 is embedded in the upper end of processing table 3, and described control box 4 is installed on The side of the processing table 3, the sliding shaft 2 is installed on the upper surface of the processing table 3, the processing device 1 is provided with a processing device 11, a fixed plate 12, a fixed rod 13, and a sliding plate 14, and the processing device 11 is embedded On the side of the fixed plate 12, the fixed rod 13 is embedded in the side of the sliding plate 14, the fixed plate 12 and the sliding plate 14 are parallel to each other, and the two ends of the sliding plate 14 are connected with the sliding shaft 2, the The sliding plate 14 is located at the lower end of the processor 11, and the sliding plate 14 and the slid...

Embodiment 2

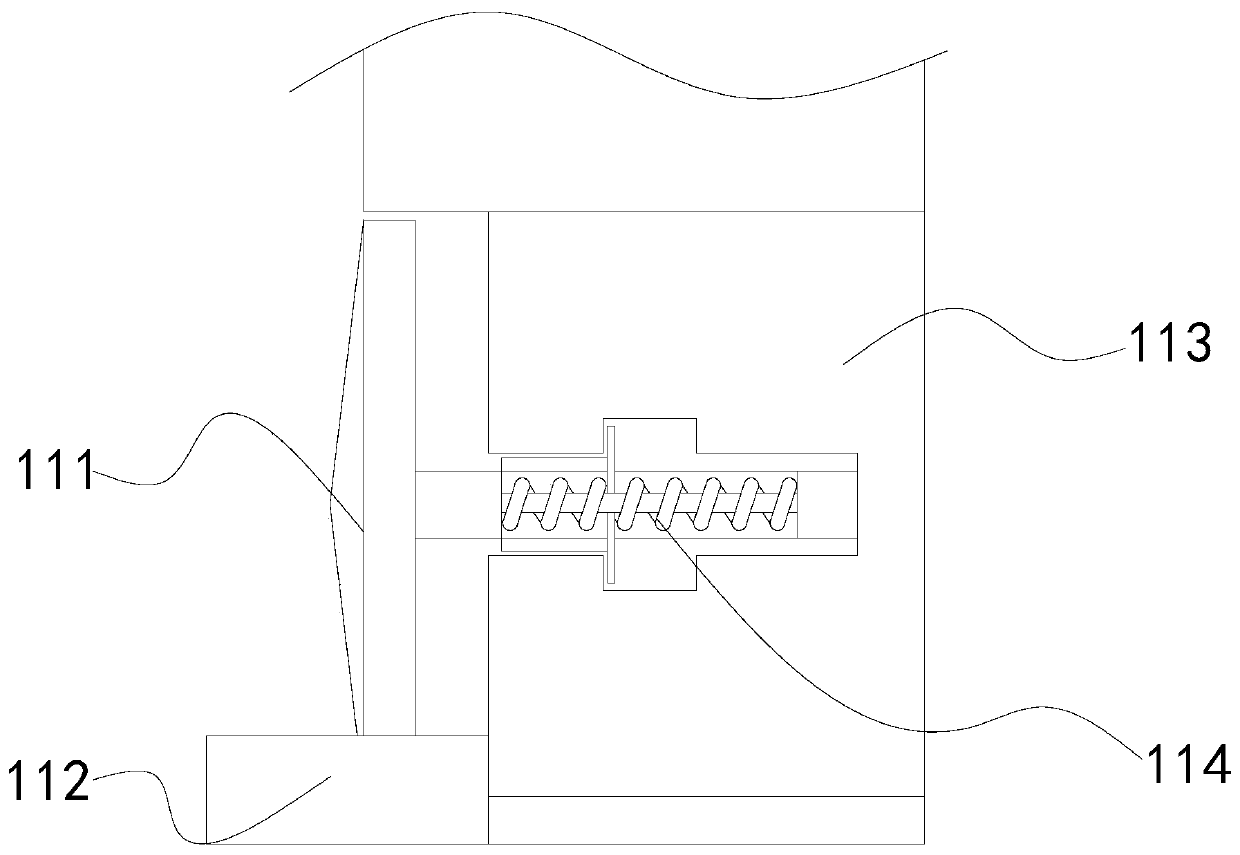

[0034] like Figure 7-Figure 8 Shown:

[0035] Wherein, the collecting device 112 is provided with an inclined plate w1, a blocking plate w2, and a filter plate w3, the outer side of the inclined plate w1 is attached to the inner side of the filtering plate w3, and the rear end of the blocking plate w2 is attached to The front end, the two sides of the blocking plate w2 are embedded and fixed on the inside of the filter plate w3, the front end of the blocking plate w2 is embedded and fixed on the left end of the fixed block 113, and there are two blocking plates w2, which are located at the two ends of the lower end of the rotating device 111. side, has the function of blocking the wear debris, prevents the wear debris falling from the rotating device 111 from splashing around, and has the effect of collecting the wear debris.

[0036] Wherein, the blocking plate w2 is provided with a blocking block w21, a flow pipe w22, a supporting block w23, and a sponge block w24, the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com