Knife sharpener

A knife sharpener and knife sharpening bar technology, which is applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problem of time-consuming processing and assembly processes, affecting the use effect of blades and production efficiency Difficult to improve and other problems, to achieve the effect of simple and fast assembly, simplify processing and assembly procedures, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

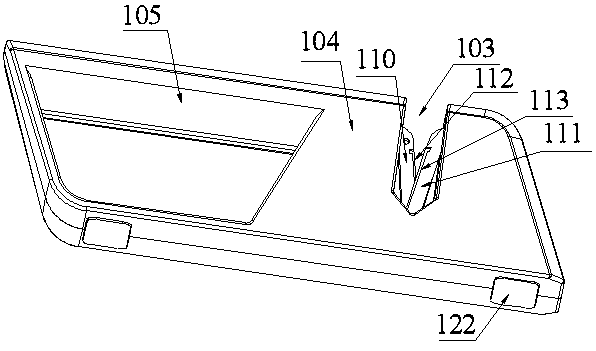

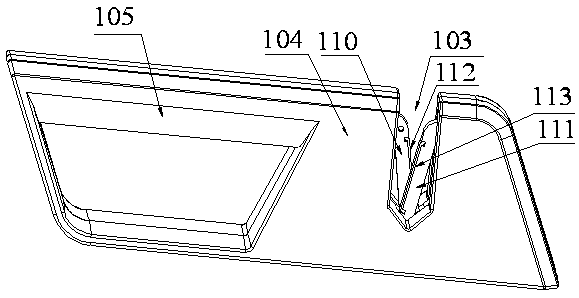

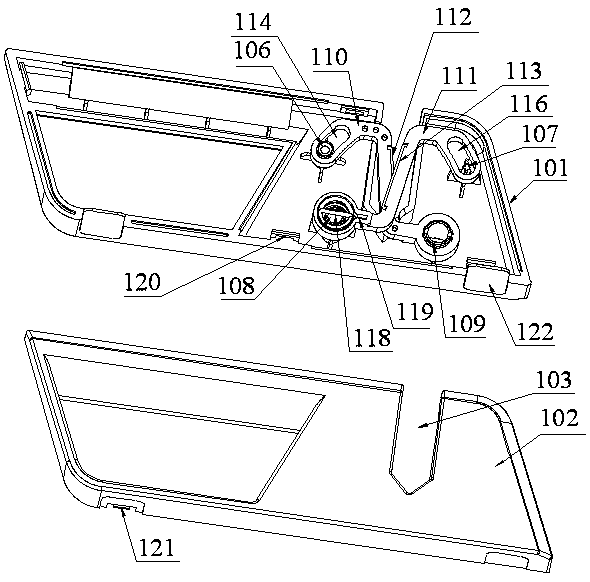

[0017] refer to Figure 1 to Figure 4 , an embodiment of a knife sharpener of the present invention is proposed, which includes a shell assembled by the first half shell 101 and the second half shell 102, and the shell includes a sharpening part 104 with a sharpening port 103, which is convenient The handle part 105 held by the human hand, the first half shell 101 and the second half shell 102 are positioned and fixed through the positioning column structure. The positioning column structure includes the first positioning column 106 located at the upper left side of the sharpening port 103, and the positioning post 106 located at the left upper end of the sharpening port. The second positioning post 107 at the upper right side of 103, the third positioning post 108 at the lower left side of the sharpening port 103, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com