A method for preparing large-scale single-crystal two-dimensional materials based on chemical vapor deposition

A technology of chemical vapor deposition and two-dimensional materials, which is applied in the field of preparing large-size single-crystal two-dimensional materials based on chemical vapor deposition, can solve the problems of difficult formation of single-crystal structures and low quality of large-size single-crystal two-dimensional materials, and reduce the The effect of preparation cost, simplification of material types, and promotion of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The Si / SiO 2 The preparation method of the substrate is: evaporating SiO from a commercial Si wafer 2 layer, and for evaporation of SiO 2 One side of the layer is polished to serve as a substrate.

[0074] Further, SiO 2 The thickness of the layer is 200-300 nm;

[0075] Further, the distance between the different temperature zones is 15-20cm;

[0076] (2) Vacuum flush the furnace cavity with inert gas;

[0077] Further, the furnace cavity is evacuated, and inert gas is introduced to the furnace cavity pressure of 0.5-1 atm, then the furnace cavity is evacuated, and the operation is repeated to perform vacuum treatment on the furnace cavity;

[0078] Further, during the vacuum flushing process of the furnace cavity, the number of repetitions is 3 to 5 times to fully ensure that there is no oxygen, water vapor and other gases unrelated to the reaction in the furnace cavity.

[0079] (3) The temperature in different temperature zones is heated up respectively, and t...

Embodiment 1

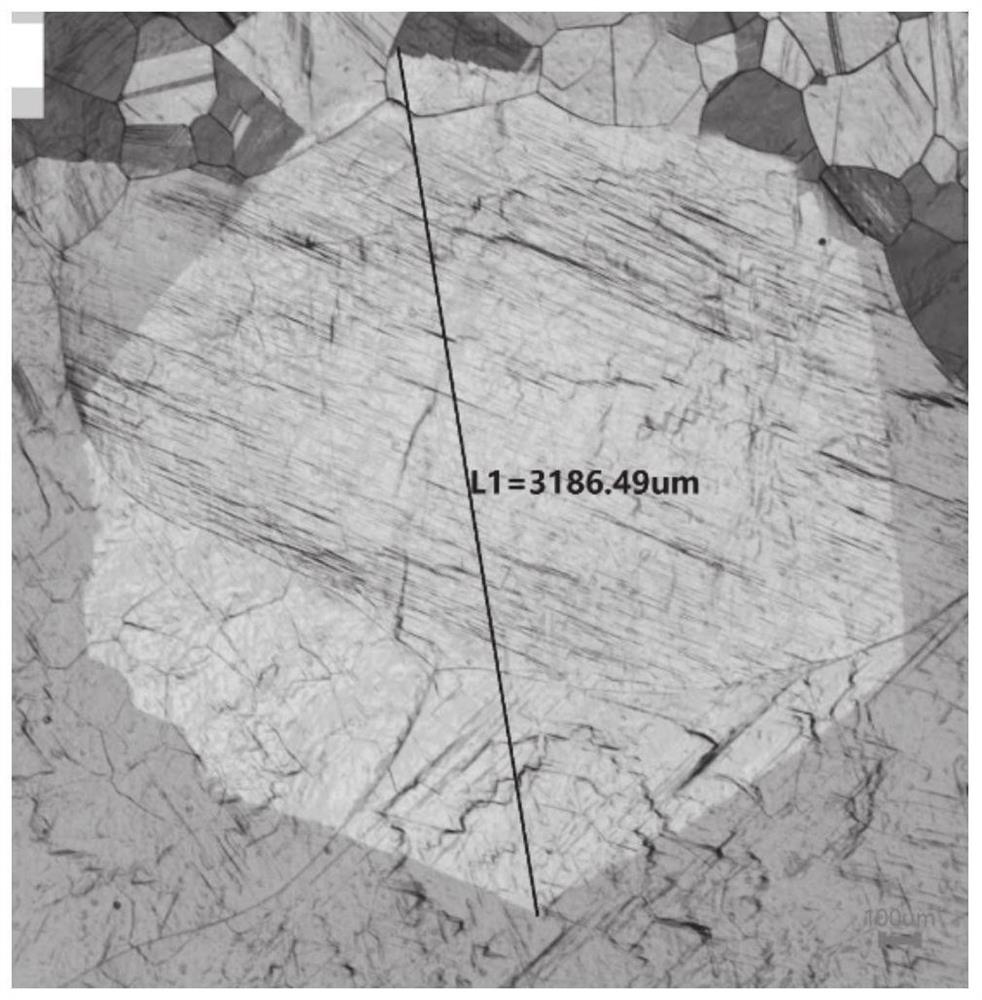

[0089] A method for preparing a large-sized single crystal two-dimensional graphene material, comprising the following steps:

[0090] (1) Select metal copper Cu as the substrate, and carry out pretreatment such as cleaning, electrochemical polishing, and oxidation;

[0091] (2) Place the pretreated Cu substrate in the reaction furnace chamber, and then evacuate the furnace chamber to 5×10 -5 Pa; close the vacuum pump unit, introduce inert gas Ar to the furnace chamber pressure of 1 atm, then turn on the vacuum pump unit, pump and charge the furnace chamber, repeat 3 times, and vacuum the furnace chamber;

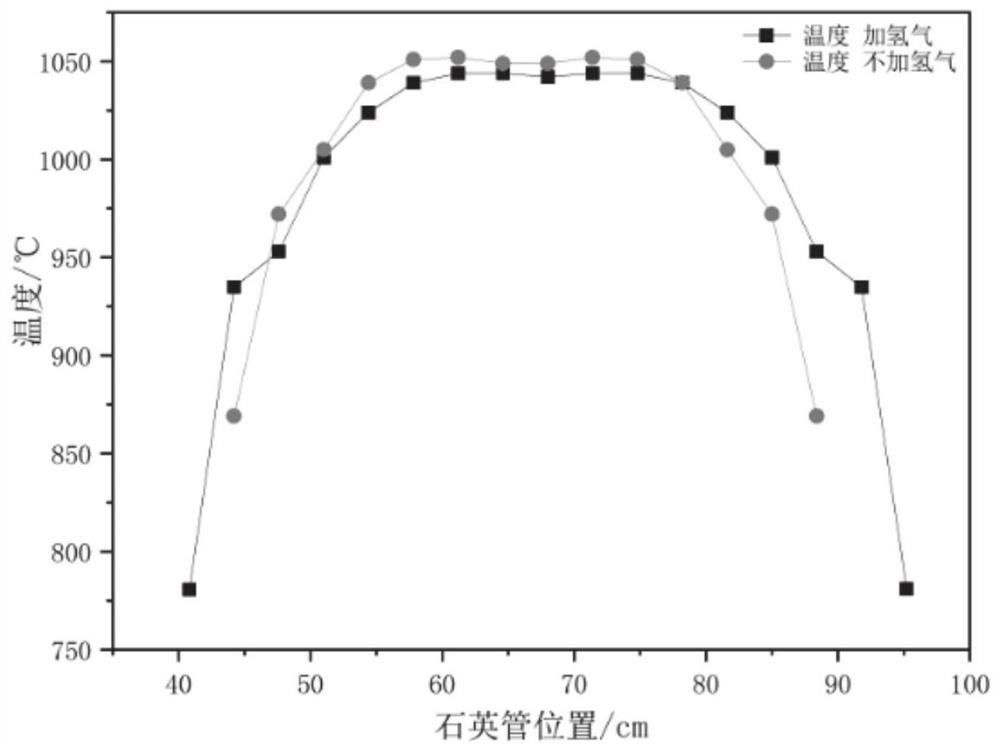

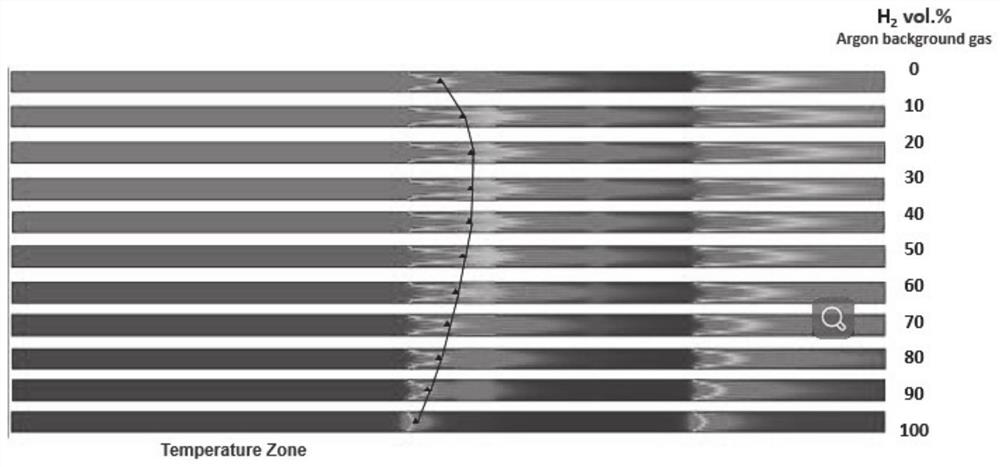

[0092](3) Raise the temperature of the equipment to 1050°C, compare with H 2 Add changes to the temperature field. Into the furnace cavity and Ar 2 (500sccm) and H 2 (10sccm) mixed gas was used as the carrier gas, the furnace chamber was adjusted to the target pressure of 0.75 atm, and the substrate was annealed for 60 min. Under this condition, the temperature field i...

Embodiment 2

[0104] A kind of preparation of large-size single crystal two-dimensional MoSe 2 The method of the material includes the following steps:

[0105] (1) Evaporate 300nm thick SiO on a commercial Si wafer 2 layer, and for evaporation of SiO 2 One side of the layer is polished as a substrate;

[0106] (2) Treated Si / SiO 2 The substrate is placed in the furnace chamber, and the polished surface is aligned with the MoO 3 Precursor; Se powder precursor is placed before the substrate with a distance of 20cm;

[0107] (3) Then the furnace cavity is evacuated, and the vacuum degree is not higher than 5×10 -5 Pa; turn off the vacuum pump unit, introduce inert background gas to the furnace chamber pressure of 1 atm, then turn on the vacuum pump unit, pump and charge the furnace chamber, repeat 3 times, and vacuum the furnace chamber;

[0108] (4) Set the programmed heating respectively, the temperature of the Se region is raised to 250°C, and the heating rate is 10°C / min; Si / SiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com