A side entry type booster mud cutting mechanism

A side-entry, mud-cutting technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problems of high labor intensity, low mud-cutting efficiency, low degree of automation and work efficiency, and achieve low use and maintenance costs. Conducive to the effect of control and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

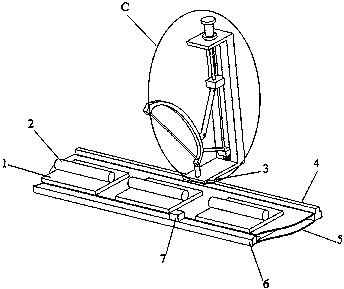

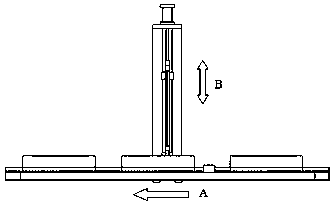

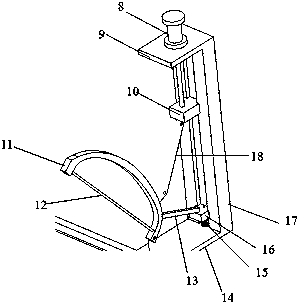

[0016] Such as figure 1 —3. Before using the device for cutting, the conveyor belt 5 is at a standstill. Place the combination of the pallet 1 and the mud column 2 on the conveyor belt 5, adjust the position of the suspension 14 on the guide rail 4 and fix it with the fixing screw 3. The mud cutting cylinder 8 moves its piston rod back into the cylinder chamber, and the slider 10 rises and drives one end of the pull rod 18, so that the knife rest 11 connected to the other end of the pull rod 18 rotates upward, and the booster rod 13 compresses the booster spring 15 to store Yes, complete the preparations.

[0017] When it is necessary to use this device to cut mud, the staff puts the mud column 2 to be cut on the supporting plate 1, and then the conveyor belt 5 is started, and the conveyor belt 5 transports the combination of the supporting plate 1 and the mud column 2 forward. When the position sensor 7. When the mud column 2 is detected, the conveyor belt 5 stops, the mud c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com