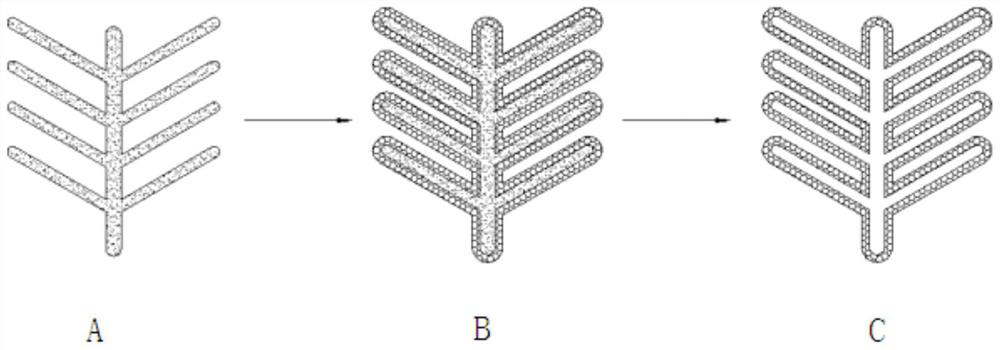

A kind of dendritic graphene and preparation method thereof

A dendritic and graphene technology, applied in graphene, chemical instruments and methods, nano-carbon and other directions, can solve problems such as graphene agglomeration, and achieve the effects of reducing other properties, fewer defects, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of dendritic graphene, comprising the steps:

[0046] 1) Under stirring, slowly add ammonia water to the copper sulfate solution (60mL, 0.03mol / L), until the pH of the solution=12, stir for 10min, and then transfer it to a stainless steel reactor lined with polytetrafluoroethylene In addition, 0.29g of red phosphorus was added, and the hydrothermal reaction was carried out under the condition of 160 °C for 4 h. After the reaction was completed, it was cooled to room temperature. The obtained red product was washed three times with deionized water and absolute ethanol, and dried at 60 °C. , that is, to obtain dendritic copper nanocrystals;

[0047] 2) Put the dendritic copper gained in step 1 into the CVD tube furnace, under the mixed atmosphere of hydrogen (flow rate is 20sccm) and argon (flow rate is 800sccm), the tube furnace is heated to 1000 at a rate of 5°C / min After ℃, the hydrogen flow rate was adjusted to 100sccm, and methane gas was introd...

Embodiment 2

[0050] A preparation method of dendritic graphene, comprising the steps:

[0051] 1) Under stirring, slowly add ammonia water to the copper nitrate solution (60mL, 0.01mol / L), until the pH of the solution=10, stir for 5min, and then transfer it to a stainless steel reactor lined with polytetrafluoroethylene In addition, 0.22g of red phosphorus was added, and the hydrothermal reaction was carried out at 140 °C for 8 hours. After the reaction was completed, it was cooled to room temperature. The obtained red product was washed three times with deionized water and absolute ethanol, and dried at 60 °C. , that is, to obtain dendritic copper nanocrystals;

[0052] 2) Put the dendritic copper obtained in step 1 into the CVD tube furnace, under the mixed atmosphere of hydrogen (flow rate is 10sccm) and argon (flow rate is 600sccm), the tube furnace is heated to 800 at a rate of 5°C / min After ℃, the hydrogen flow rate was adjusted to 80sccm, and ethylene gas was introduced at a flow r...

Embodiment 3

[0055] A preparation method of dendritic graphene, comprising the steps:

[0056] 1) Under stirring, slowly add ammonia water to the cupric chloride solution (60mL, 0.05mol / L) until the pH of the solution=11, stir for 30min, and then transfer it to the stainless steel reaction lined with polytetrafluoroethylene In the kettle, 0.20g of red phosphorus was added, and the water was kept at 180°C for 2 hours to carry out a hydrothermal reaction. After the reaction was completed, it was cooled to room temperature. The obtained red product was washed three times with deionized water and absolute ethanol, respectively. drying to obtain dendritic copper nanocrystals;

[0057] 2) Put the dendritic copper gained in step 1 into the CVD tube furnace, under the mixed atmosphere of hydrogen (flow rate is 30sccm) and argon (flow rate is 1000sccm), the tube furnace is heated to 900 at a rate of 5°C / min After ℃, the hydrogen flow rate was adjusted to 120 sccm, and acetylene gas was introduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com