Manufacturing process of synthetic leather shoes

A production process and technology of synthetic leather, applied in the field of production technology of synthetic leather shoes, can solve the problems of insufficient moisture absorption and air permeability, low tensile strength of synthetic leather, users sweating and smelly feet, etc. The effect of whitening feet, improving smoothness, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

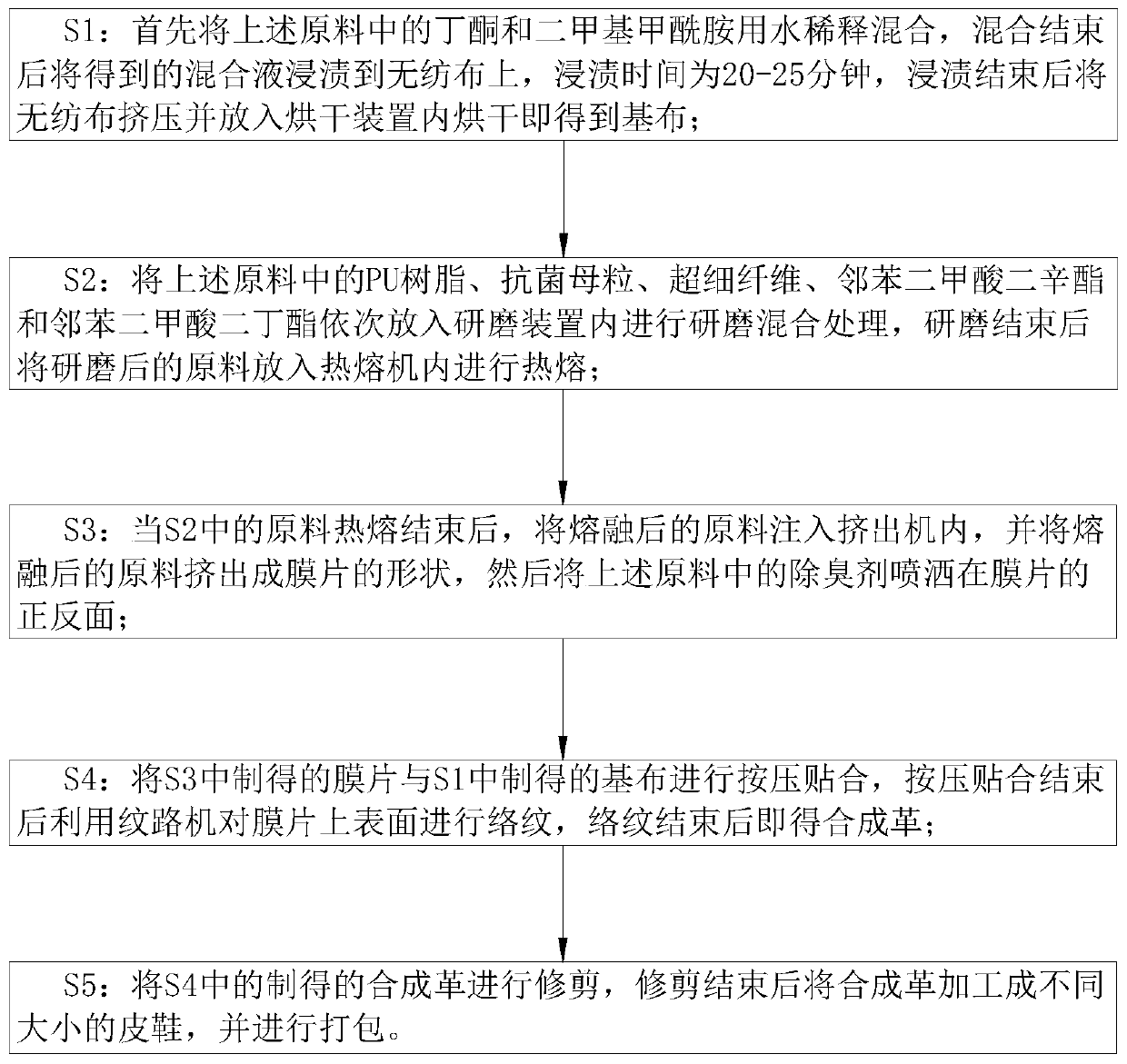

Method used

Image

Examples

Embodiment approach

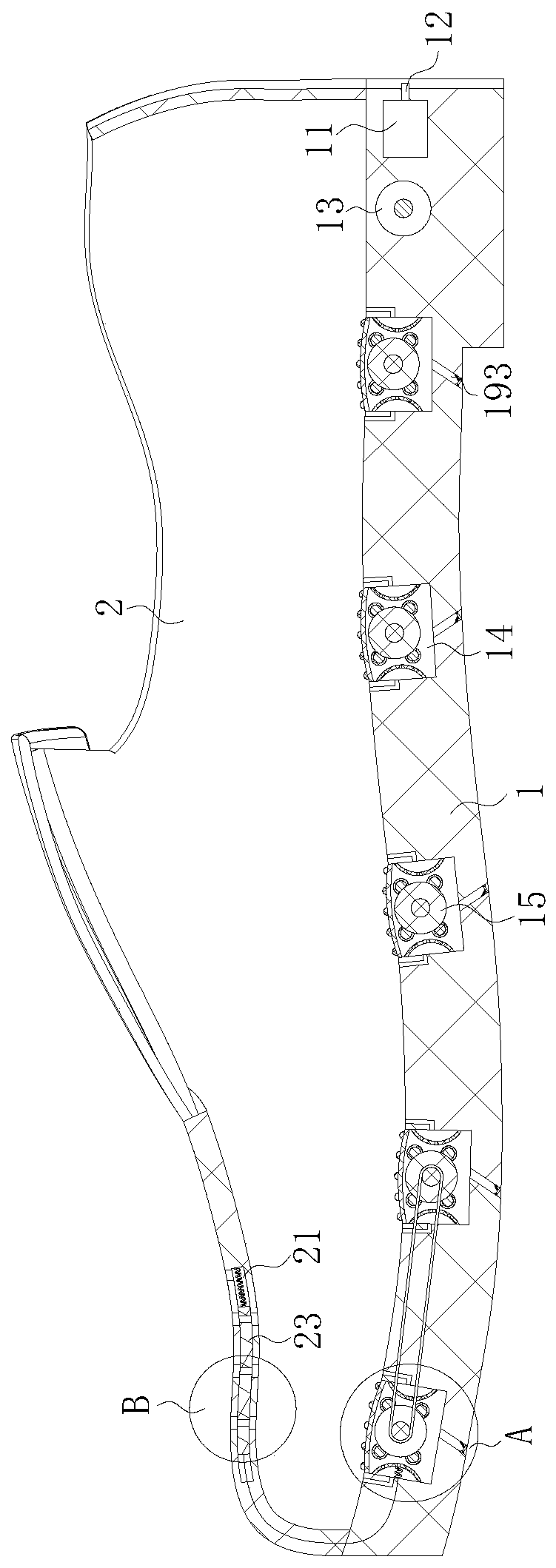

[0050] As an embodiment of the present invention, a chute 21 is provided at the top corner of the upper 2 in the inner wall of the upper 2; first air holes 22 evenly arranged are opened in the inner wall of the chute 21, and the first air holes 22 are uniformly arranged. Through the design of the upper 2; the slide groove 21 is slidably connected with a slider 23 through a spring, and the slider 23 is made of memory rubber material; the inner wall of the slider 23 is provided with second air holes 24 evenly arranged, and the second The two air holes 24 correspond to the first air holes 22 in the initial state; the left side of the slider 23 is fixedly connected with a stay cord 25, and the stay cord 25 extends into the inner wall of the sole 1 and is fixed to the leftmost bag layer 19. Connect; the capsule layer 19 on the left side is fixedly connected with a spring;

[0051] When working, the toes of the leather shoes in the prior art will bend due to long-term walking, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com