Mashing device of raw material extraction equipment for cosmetic production

A technology for extracting equipment and cosmetics, which is applied in the field of crushing devices of raw material extraction equipment for cosmetics production, which can solve the problems of low crushing efficiency and difficult plant extrusion, and achieve the effect of increasing crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

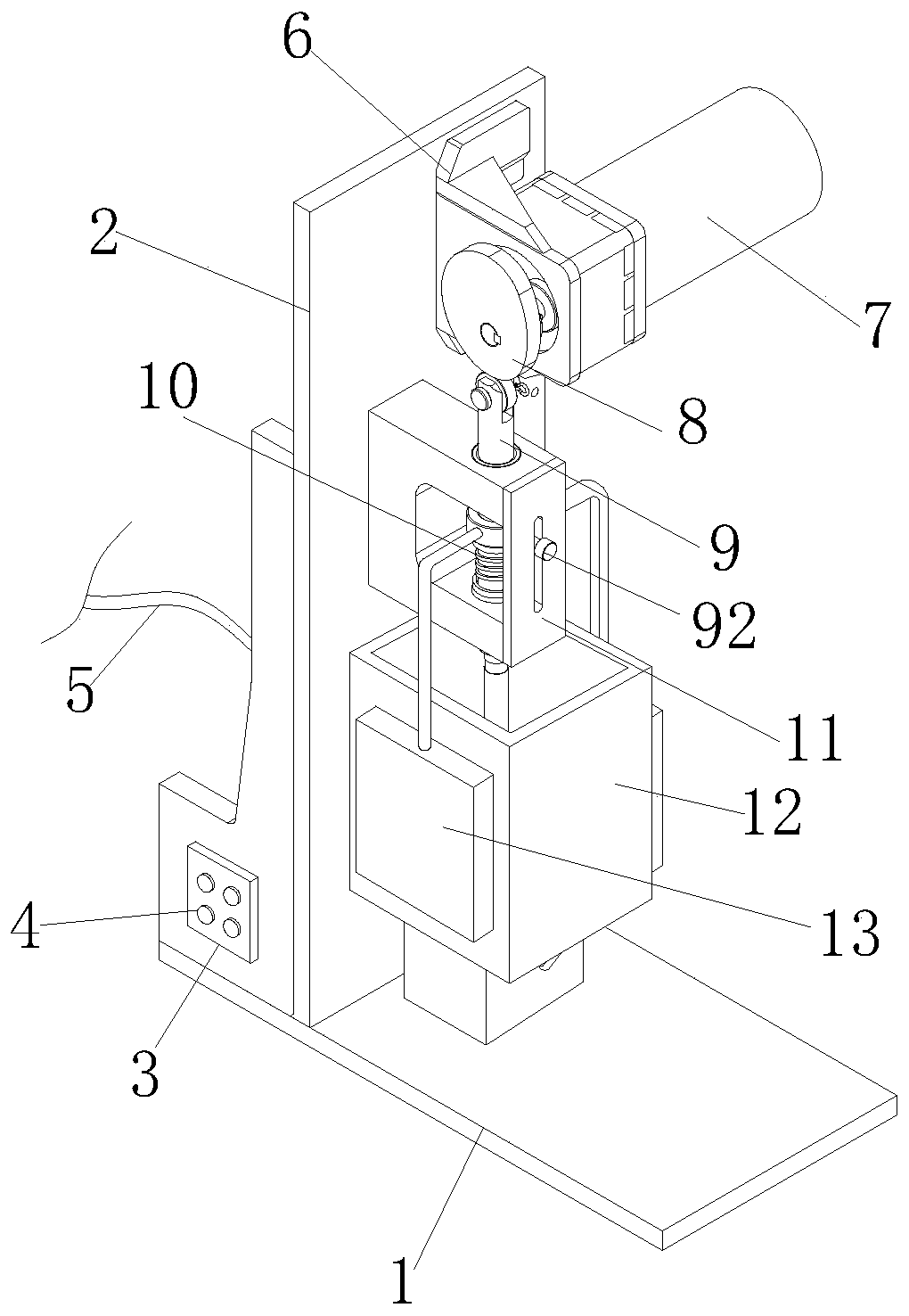

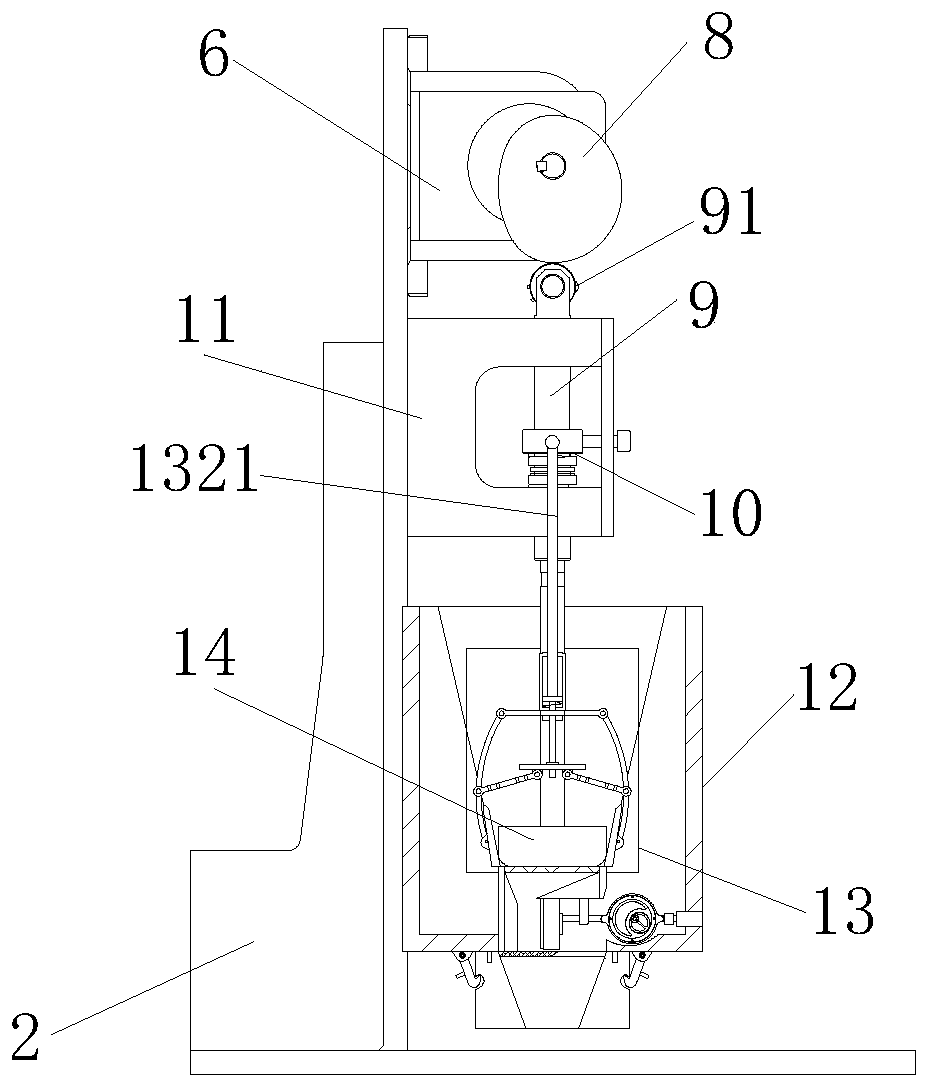

[0034] see figure 1 with figure 2, the present invention provides a mashing device for raw material extraction equipment for cosmetic production through improvement, including a bottom plate 1, a vertical plate 2, a cam 8, a beating frame 12, a hammer head 14 and a centralized extrusion mechanism 13, the bottom plate 1 and the vertical The bottom of the plate 2 is fixed as a whole, the lower left end of the front end of the vertical plate 2 is provided with a control panel 3, the front end of the control panel 3 is equipped with a button 4, the left end of the vertical plate 2 is fixed with a power wire 5, the vertical plate 2 is connected with the left end of the fixing ring 6 by bolts, fixed The ring 6 is locked and fixed with the front end of the first motor 7 by screws, the output end of the first motor 7 is connected to the cam 8 in rotation, the centralized extrusion mechanism 13 is installed and fixed inside the beating frame 12 and at the front and rear ends, the cam ...

Embodiment 2

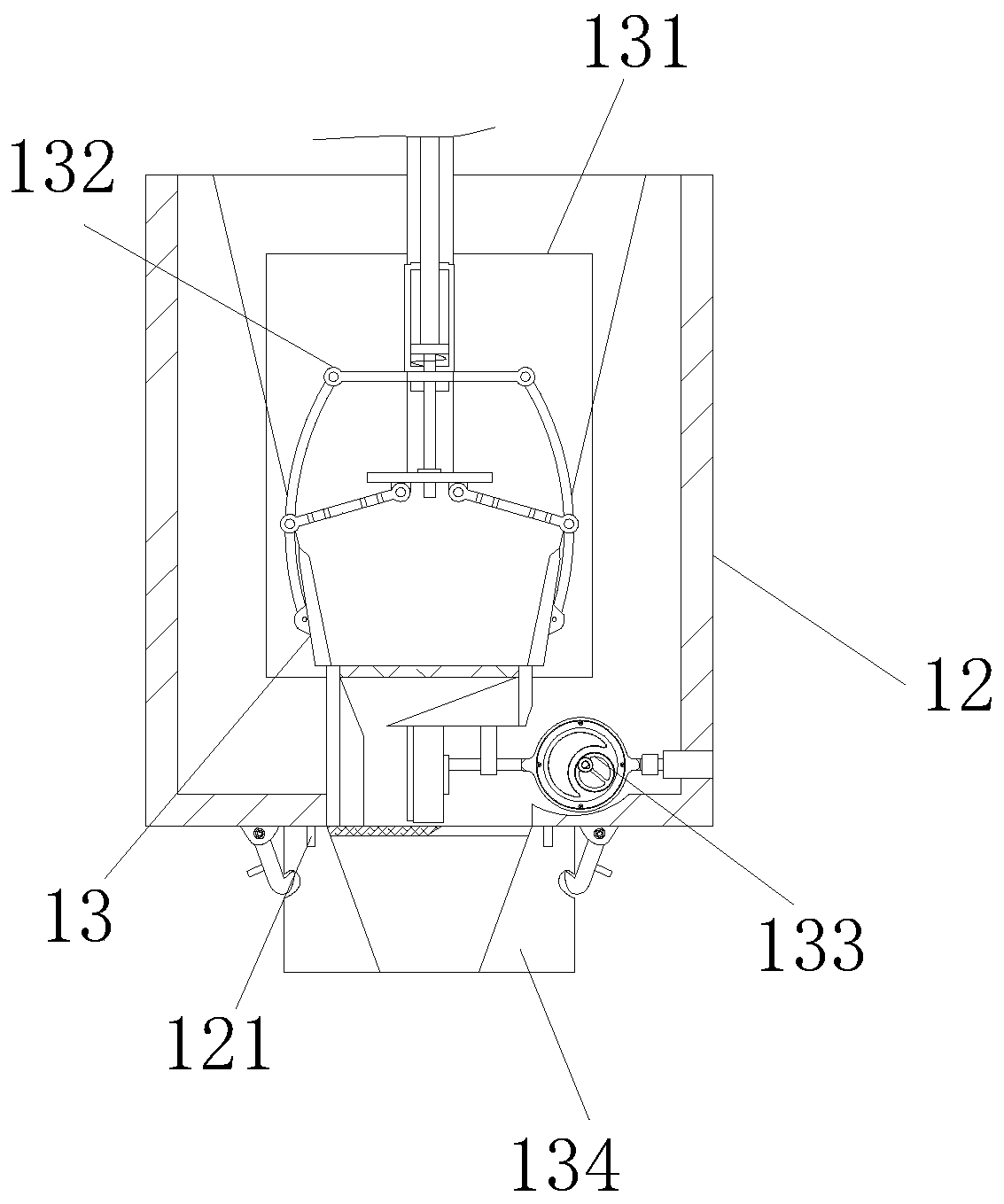

[0041] The present invention provides a crushing device for raw material extraction equipment for cosmetics production through improvement. There are two protective frames 131, and the protective frames 131 are symmetrically distributed along the front and rear ends of the beating frame 12. The two protective frames 131 insides are all equipped with a concentration mechanism 132, which is beneficial to play the role of concentrating the plants. The lower end of the beating frame 12 is provided with an insertion rod 121, and the insertion rod 121 is plugged and fixed with the inner side wall of the slot 1342, and the inside of the beating frame 12 is gradually reduced. The cavity shape is conducive to the discharge and compression of plants. The upper end of the hammer rod 9 is provided with a pressure wheel 91, and the pressure wheel 91 is closely attached to the lower end of the cam 8. The right end of the hammer rod 9 is provided with a guide rod 92, and guides The rod 92 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com