Plastic spraying rotating shaft cover processing tooling and application method thereof

A shaft and plastic technology, which is applied in the field of plastic spraying shaft cover processing tooling and processing tooling, can solve the problems of inability to store tools and processed parts, adjust the height of the shaft cover, and the fixing mechanism is not very firm, etc., to prevent shaking or falling off , firm fixation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

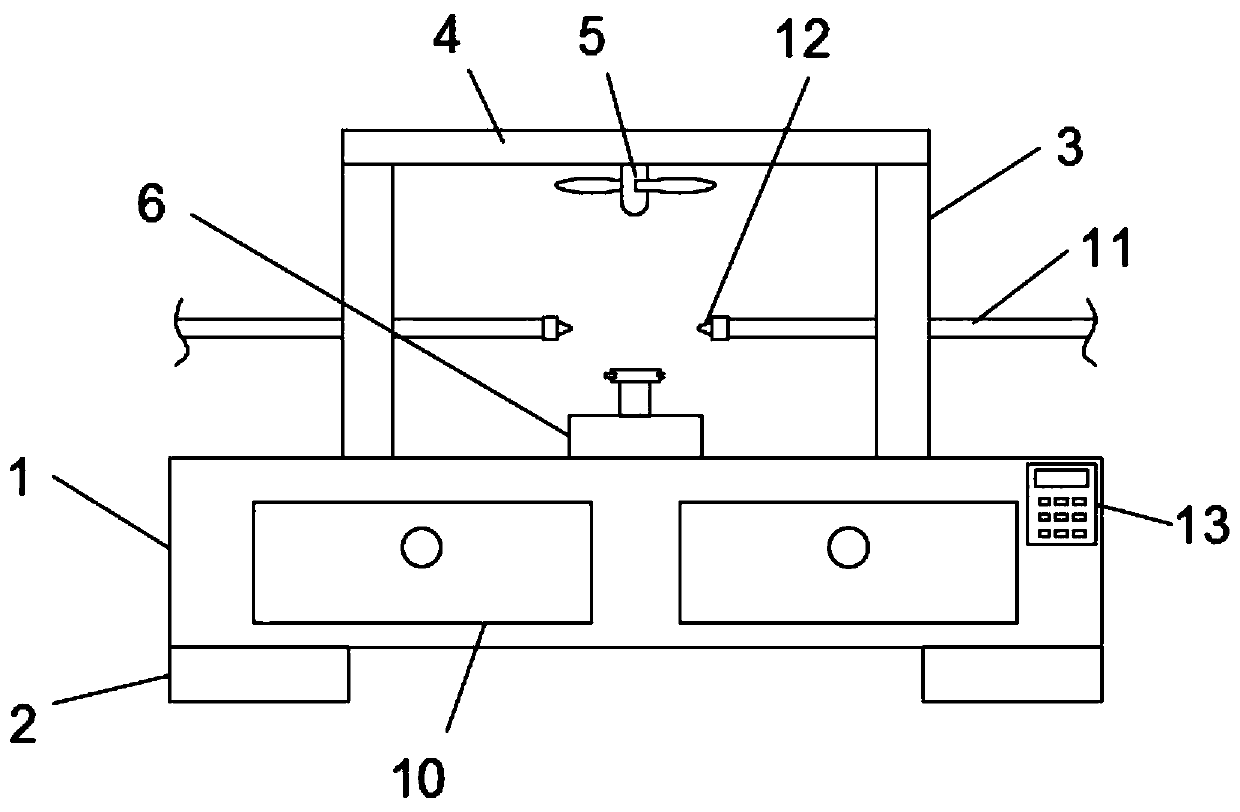

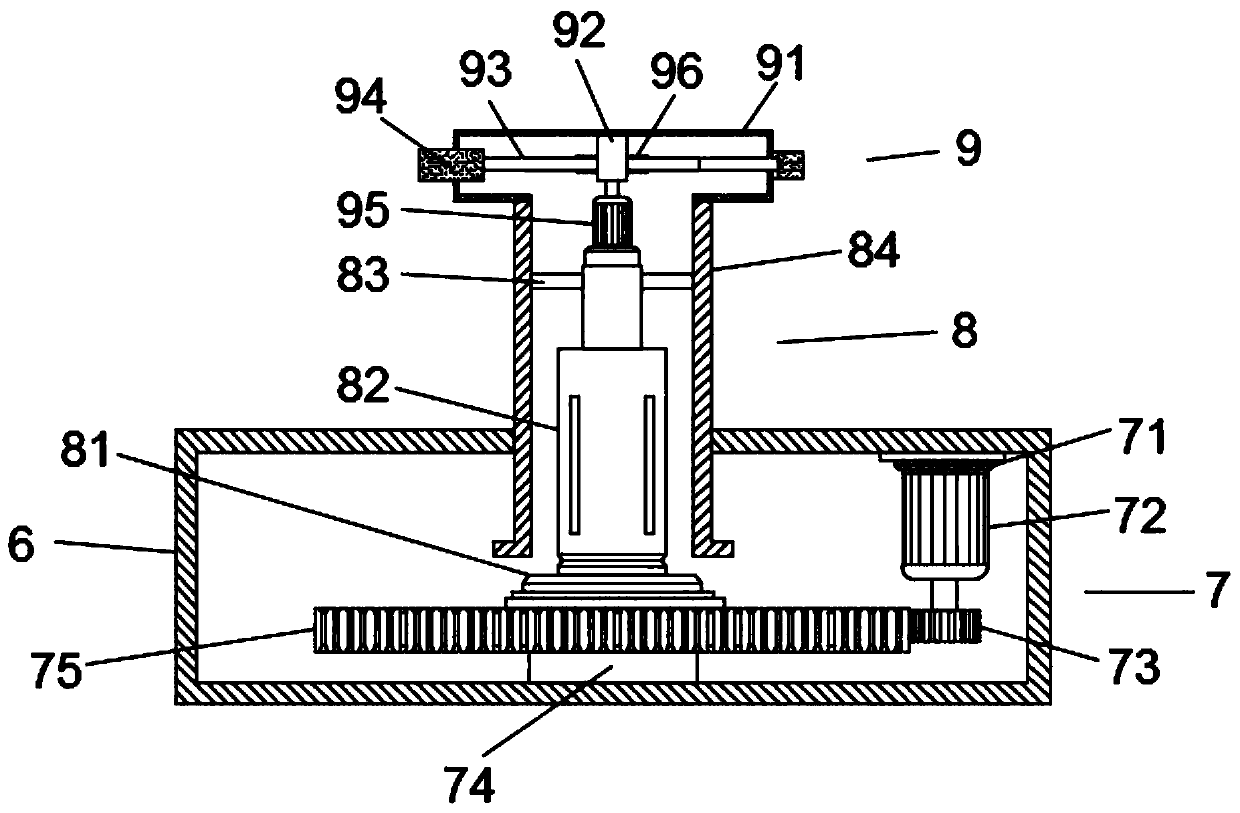

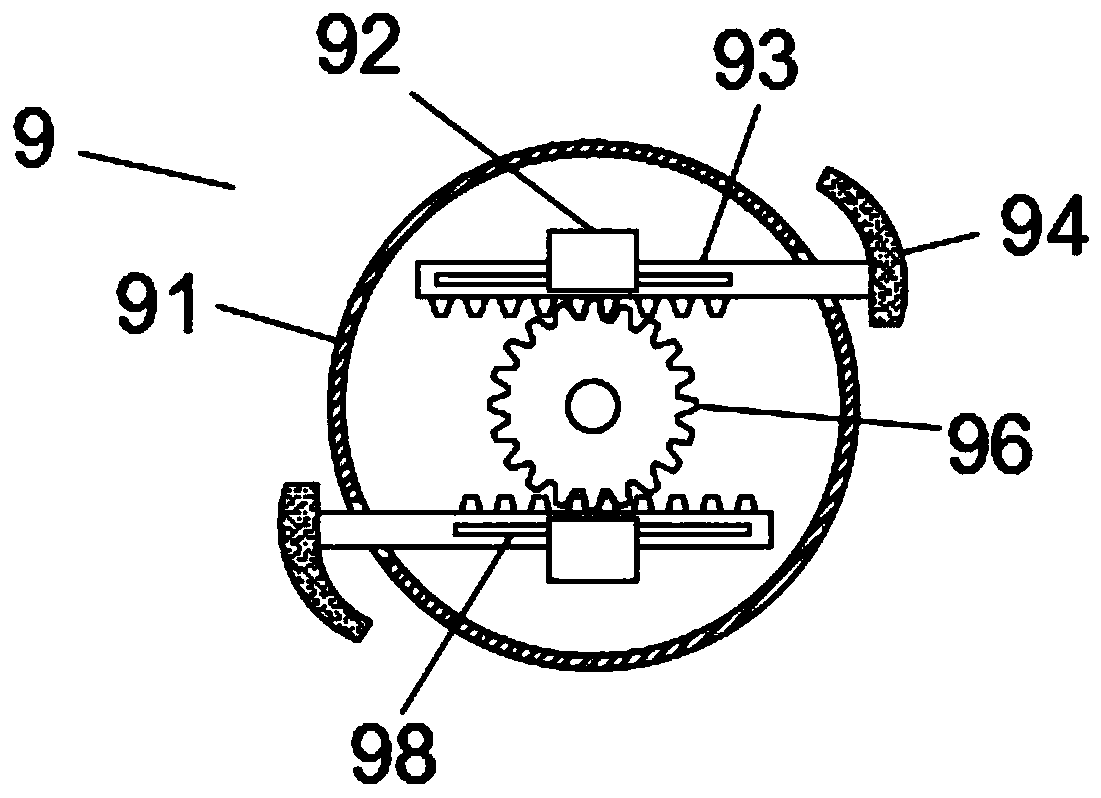

[0030] Such as Figure 1-5 As shown, the present invention provides a plastic spraying shaft cover processing tool, including a workbench 1, a foot 2, a bracket 3, a top plate 4, an electric fan 5, a base 6, a rotating mechanism 7, a lifting mechanism 8, a supporting mechanism 9, and a connecting pipe 11 , nozzle 12, control panel 13, the four corners of the bottom of the workbench 1 are fixedly connected with support feet 2, both ends of the top of the workbench 1 are fixedly connected with brackets 3, the tops of the two brackets 3 are fixedly connected with a top plate 4, and the top of the top plate 4 An electric fan 5 is fixedly installed, and the top of the workbench 1 is fixedly connected with a base 6 directly below the electric fan 5. The inside of the base 6 is provided with a rotating mechanism 7, and the top of the rotating mechanism 7 is provided with a lifting mechanism 8. The top of the lifting mechanism 8 A support mechanism 9 is provided, and the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com