Rubber raw material transportation device

A technology for transportation device and rubber raw material, which is applied in the field of rubber raw material transportation device, which can solve the problems of rubber raw material deviation, device imbalance, rubber material slipping and damage to the floor, etc., to avoid deviation, good protection, and avoid slipping Effect on floor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

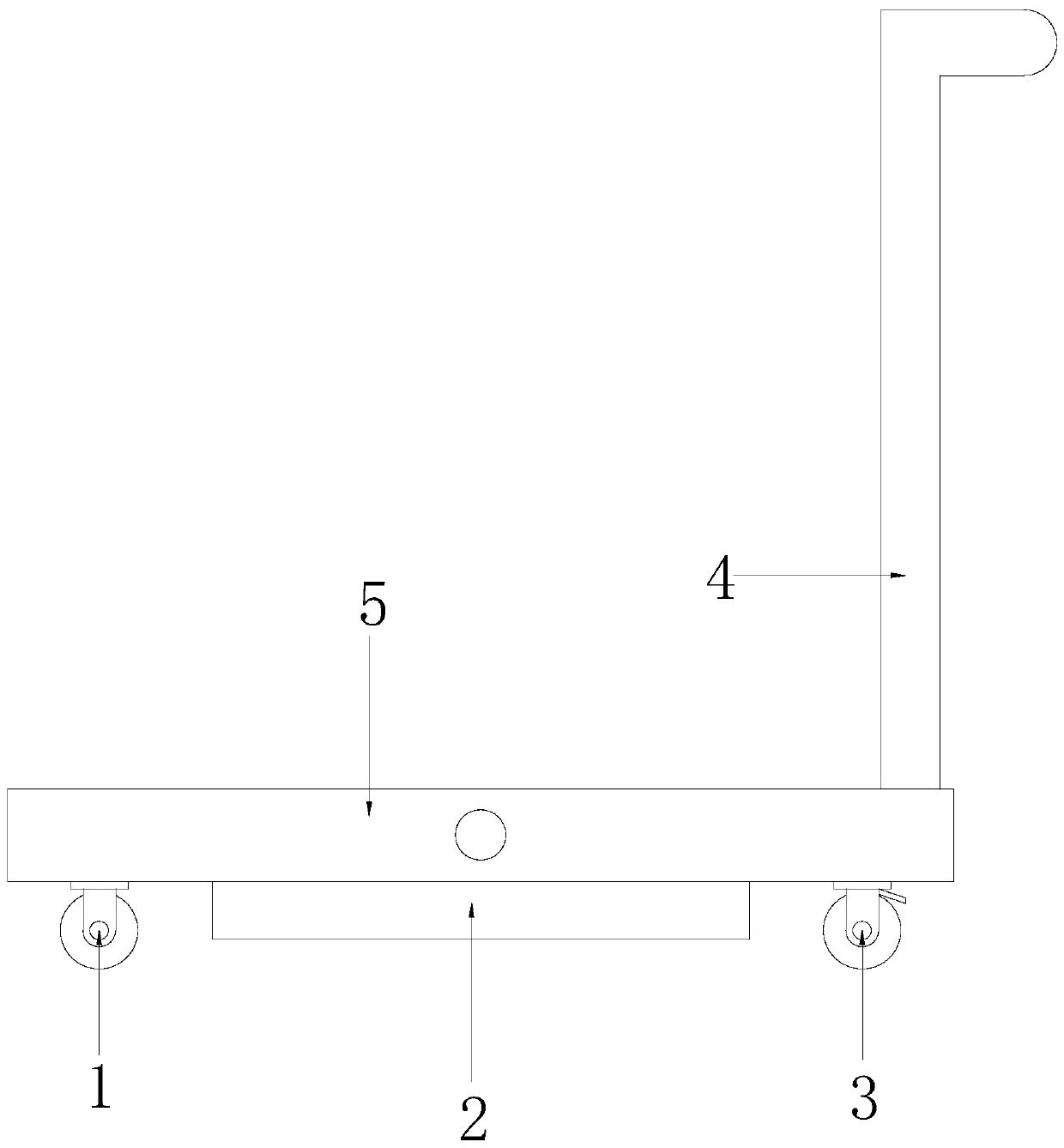

[0037] see figure 1, the present invention provides a technical solution of a rubber raw material transportation device: its structure includes a directional wheel 1, a gripping fixing device 2, a universal wheel 3, an armrest frame 4, and a transportation base 5, and one side of the transportation base 5 has two sides. Both ends are fixed with directional wheels 1, and the two ends of the other side are equipped with universal wheels 3, between the universal wheels 3 and the directional wheels 1, a gripping fixing device 2 is arranged, and the gripping fixing device 2 and the transport base 5 are connected to the bottom surface, and the transport base 5 is also provided with a handrail frame 4;

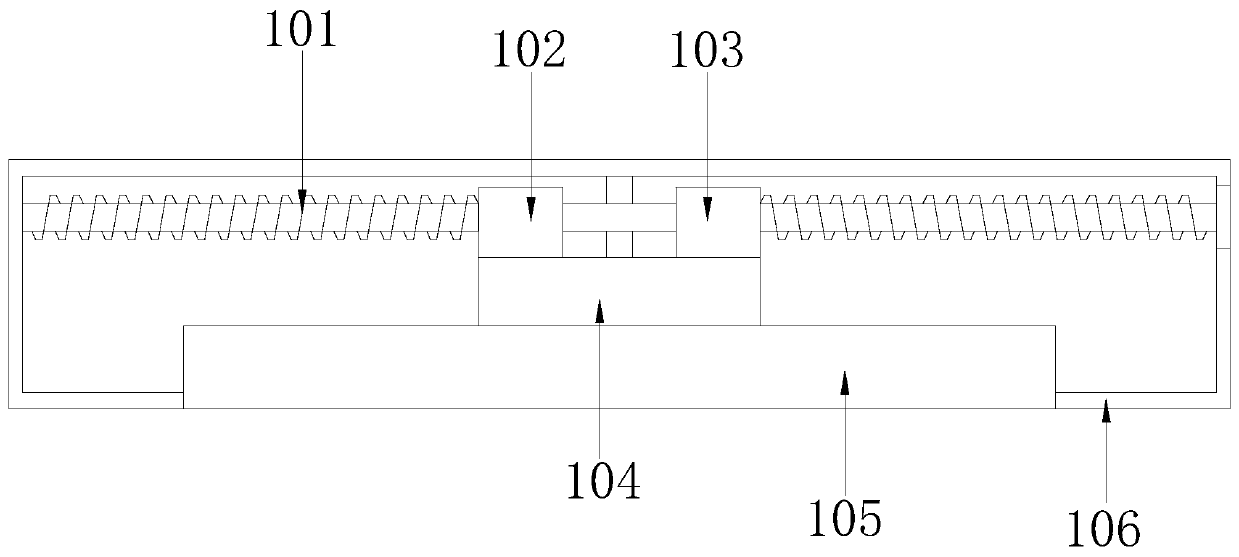

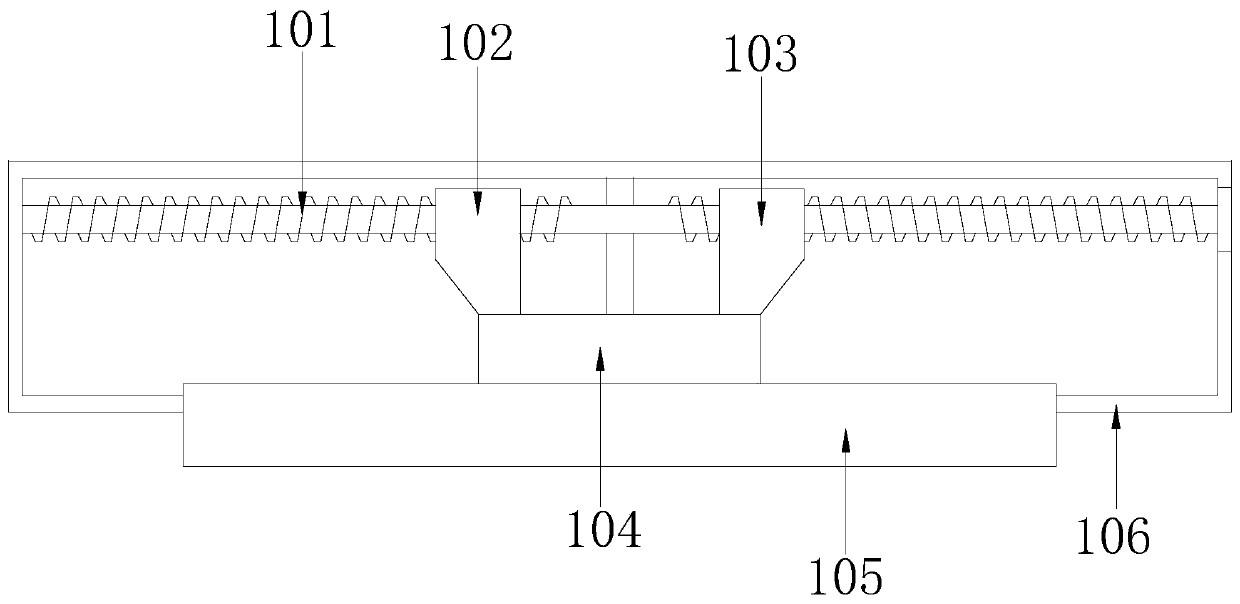

[0038] see Figure 1-3 , the gripping and fixing device 2 includes a two-way threaded screw rod 101, No. 1 moving block 102, No. 2 moving block 103, a lifting and lowering component 104, a suction cup gripping mechanism 105, and a chassis 106. The chassis 106 has a built-in lifting...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution of a rubber raw material transportation device: its structure includes a directional wheel 1, a gripping fixing device 2, a universal wheel 3, an armrest frame 4, and a transportation base 5, and one side of the transportation base 5 has two sides. Both ends are fixed with directional wheels 1, and the two ends of the other side are equipped with universal wheels 3, between the universal wheels 3 and the directional wheels 1, a gripping fixing device 2 is arranged, and the gripping fixing device 2 and the transport base 5 are connected to the bottom surface, and the transport base 5 is also provided with a handrail frame 4;

[0044] see Figure 1-3 , the gripping and fixing device 2 includes a two-way threaded screw rod 101, No. 1 moving block 102, No. 2 moving block 103, a lifting and lowering component 104, a suction cup gripping mechanism 105, and a chassis 106. The chassis 106 has a built-in liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com