Automatic opening device and process for emulsion explosive package

An emulsion explosive and automatic technology, applied in packaging and other directions, can solve problems such as bag jamming, small contact surface, and affect work efficiency, and achieve the effect of simple structure, small contact surface, and stable opening of the bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

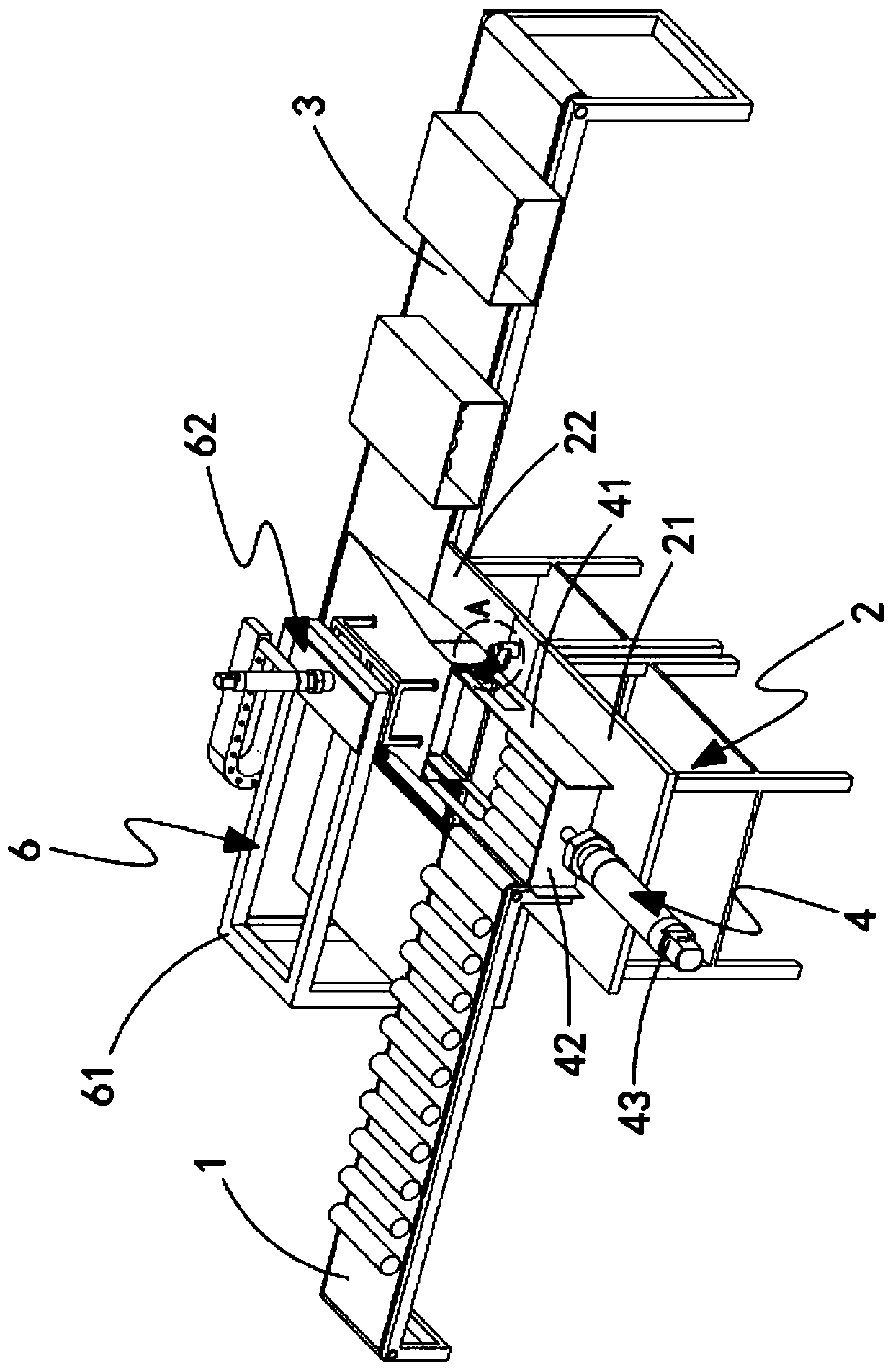

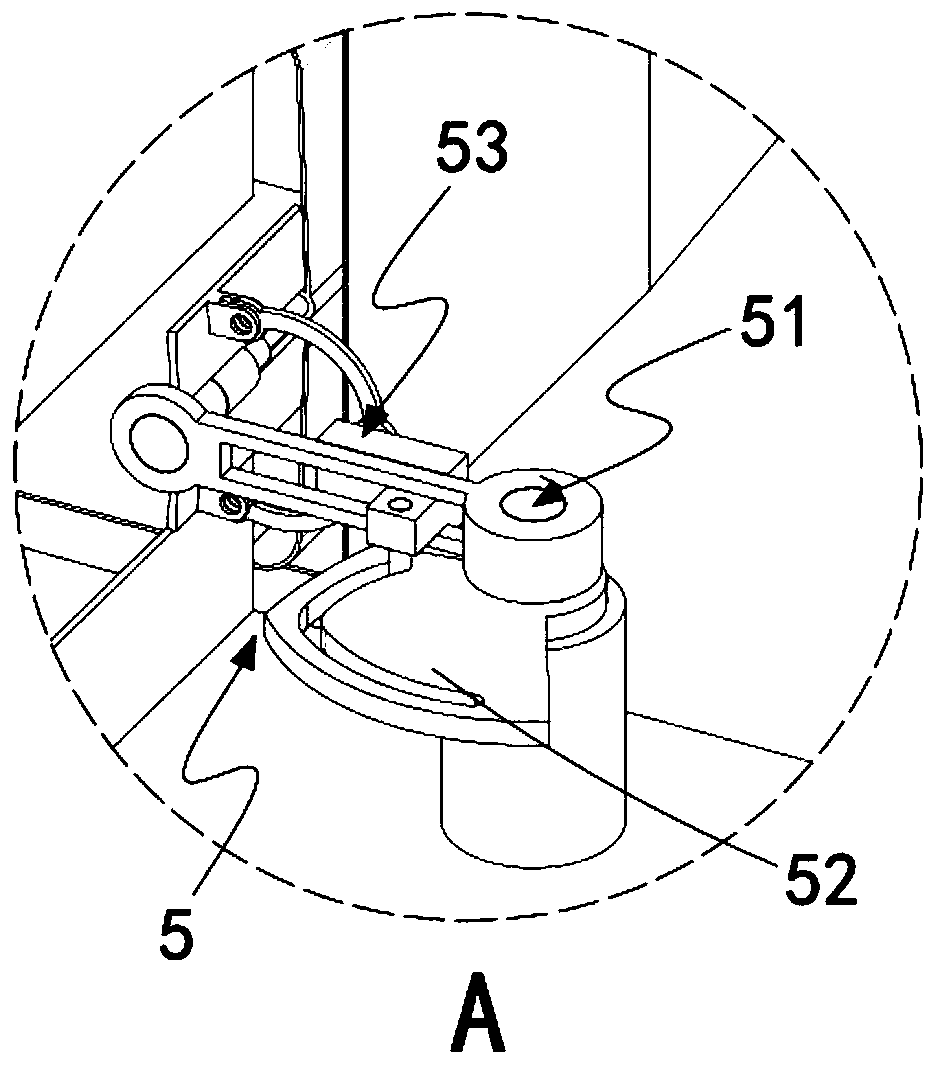

[0064] Refer to the attached Figure 1 to Figure 3 An automatic expansion device for emulsion explosive packaging according to Embodiment 1 of the present invention is described.

[0065] like Figure 1 to Figure 3 As shown, an automatic expansion device for emulsion explosive packaging includes a strip conveyor belt 1, a workbench 2 and a finished product conveyor belt 3, and is characterized in that the workbench 2 is provided with a first workbench 21 and a second workbench 22. The strip conveyor belt 1 is set above the first workbench 21, the finished product conveyor belt 3 is set at the end of the second workbench 22, and its conveying plane is the same as that of the first workbench 21. The upper table top of the second workbench 22 is flat, and also includes:

[0066] Material strip finishing mechanism 4, described material strip finishing mechanism 4 is arranged on the described first workbench 21, and described material strip finishing mechanism 4 comprises limitin...

Embodiment 2

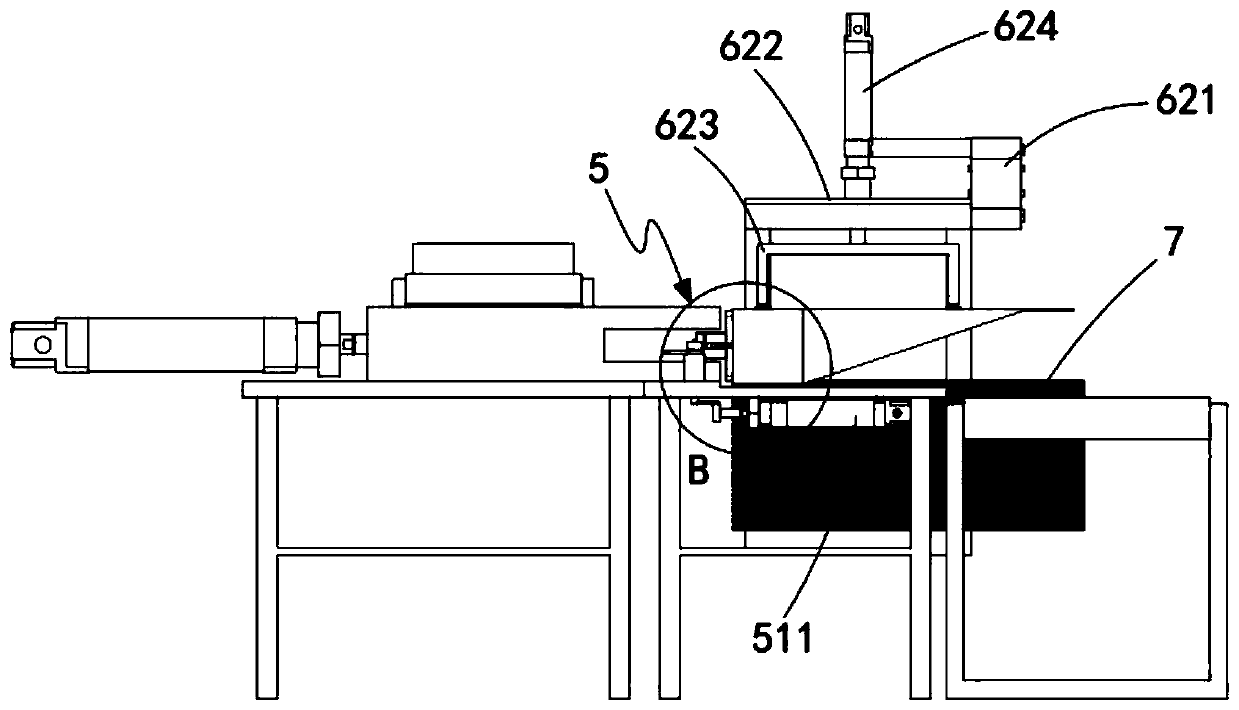

[0100] Reference attached figure 1 A production process for automatic expansion of emulsion explosive packaging according to Embodiment 2 of the present invention is described.

[0101] An automatic expansion production process for emulsion explosive packaging, characterized in that it comprises the following steps:

[0102] Step 1, the feeding process, the emulsion explosive strips are conveyed side by side by the strip conveyor belt 1;

[0103] Step 2, the sorting process, realizes the stacking of the strips by the strip sorting mechanism 4, and pushes the neatly stacked strips to the second workbench 22 at the same time;

[0104]Step 3, the bag taking process, the bag taking mechanism 6 utilizes the air negative pressure adsorption method to suck the material bag from the support 61, and transfers the material bag to the second workbench 22, and the bag taking assembly 62 on the bag taking mechanism 6 cooperates with the second The first negative pressure suction head 223...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap