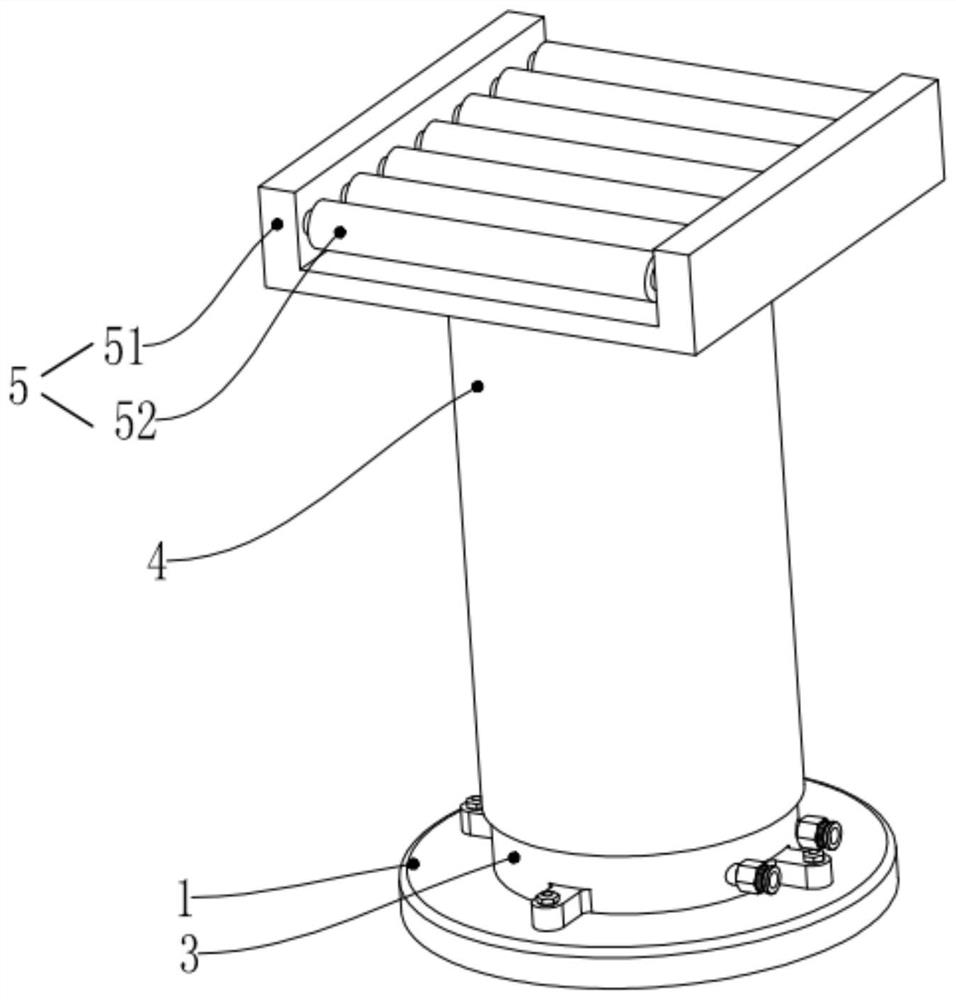

A single power source lifting rotating device and production line conveyor belt for production line

A single power source, rotating device technology, applied in the direction of lifting devices, lifting frames, conveyor objects, etc., can solve the problems that the workpiece cannot be turned accurately, the structure of the device is complicated, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

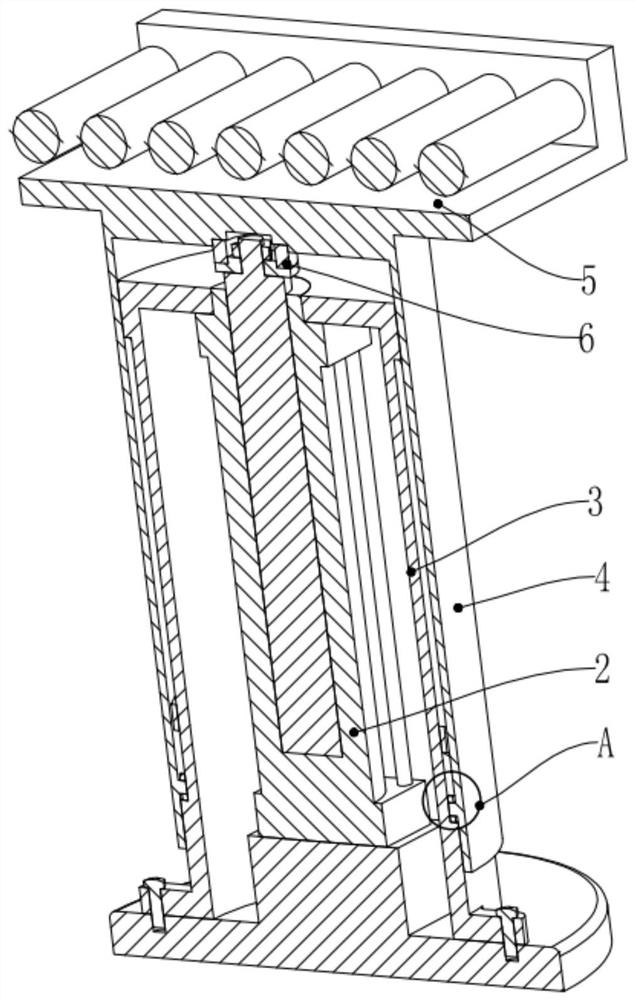

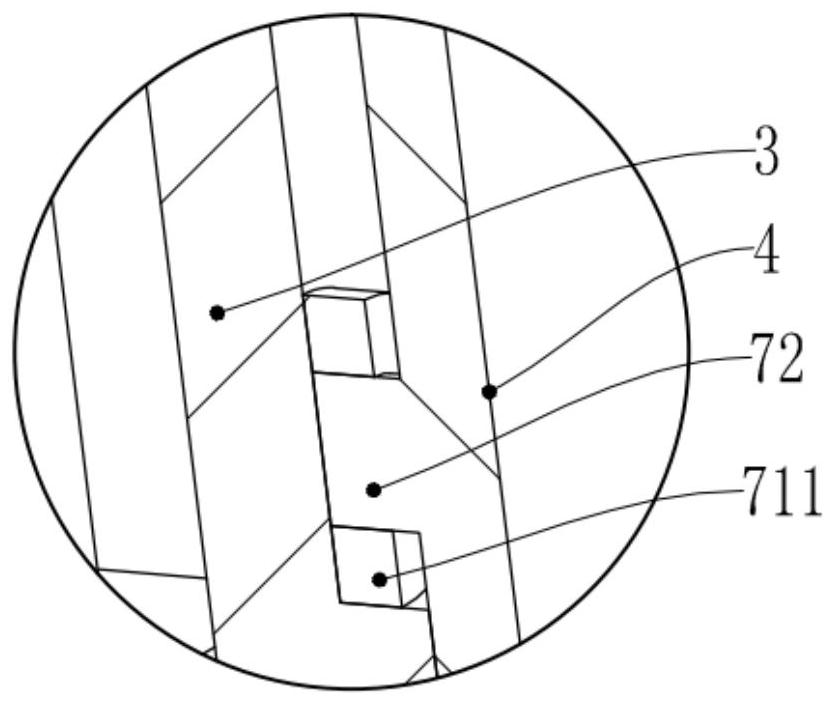

[0067] Such as Figure 6 , the movable cylinder 4 is arranged on the outside of the fixed cylinder 3, the inside of the movable cylinder 4 is provided with a movable part 72, and the outer wall of the fixed cylinder 3 is provided with a guide part 71; Under the guidance of 711, the movable part 72 enters from the lower entrance 76, and rotates a certain angle a along the annular lifting groove 711 (the annular lifting groove 711 is in the side of the columnar fixed cylinder 3, the lower entrance 76 of the annular lifting groove 711 and the upper side The angle formed between the entrances 75 is a) When reaching the upper entrance 75 of the annular lifting groove 711, the transmission device 5 connected to the movable cylinder 4 will also rotate at an angle a synchronously; at the same time, when the movable part 72 enters from the annular lifting groove 711 In the vertical lifting groove 712, under the guiding action of the vertical lifting groove 712 and the reset driving act...

Embodiment 2

[0069] Such as Figure 5 and Figure 7 , the number of mobile slot units is 2; the lower entrance 76 of the annular lift slot 711 in the first mobile slot unit 01 is connected to the lower end 7122 of the vertical lift slot 712 in the second mobile slot unit 02; a single annular lift slot The angle a formed between the lower inlet 76 and the upper inlet 75 of 711 is 180 degrees. The movable cylinder 4 is arranged on the outside of the fixed cylinder 3, the inside of the movable cylinder 4 is provided with a movable part 72, and the outside of the fixed cylinder 3 is provided with a guide part 71; in this embodiment, both the vertical lifting groove and the annular lifting groove 711 are fixed. , the movable part moves relative to both the vertical lift trough and the annular lift trough 711;

[0070] When the vertical driver 2 drives the movable cylinder 4 to rise, under the guiding effect of the annular lifting groove 711, the movable part 72 enters from the lower entrance ...

Embodiment 3

[0080] Based on Embodiment 2, Embodiment 3 is that both the vertical lift groove and the annular lift groove 711 rotate relative to the movable part, and the movable part does not move. The movable cylinder 4 is arranged on the outside of the fixed cylinder 3, the outside of the fixed cylinder 3 is provided with a movable part 72, and the inside of the movable cylinder 4 is provided with a guide part 71; as Figure 8 , the number of mobile slot units is 2; the lower entrance 76 of the annular lift slot 711 in the first mobile slot unit is connected to the lower end 7122 of the vertical lift slot 712 in the second mobile slot unit; the single annular lift slot 711 The angle a formed between the lower inlet 76 and the upper inlet 75 is 180 degrees.

[0081] At the same time, based on Embodiment 2, the movable part 72, the input limiter 73 and the output limiter 74 of the third embodiment are opposite to those of Embodiment 2, as follows:

[0082] In the initial state, the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com