Plate chain composite crusher with adjustable crushing ratio

A crushing ratio and composite technology, applied in the field of mining machinery, can solve the problems of energy consumption, occupying open space, cumbersome crushing process, etc., and achieve the effect of simple and compact structure, low energy consumption of operation, and large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The above technical solutions will be described in detail below with reference to the accompanying drawings.

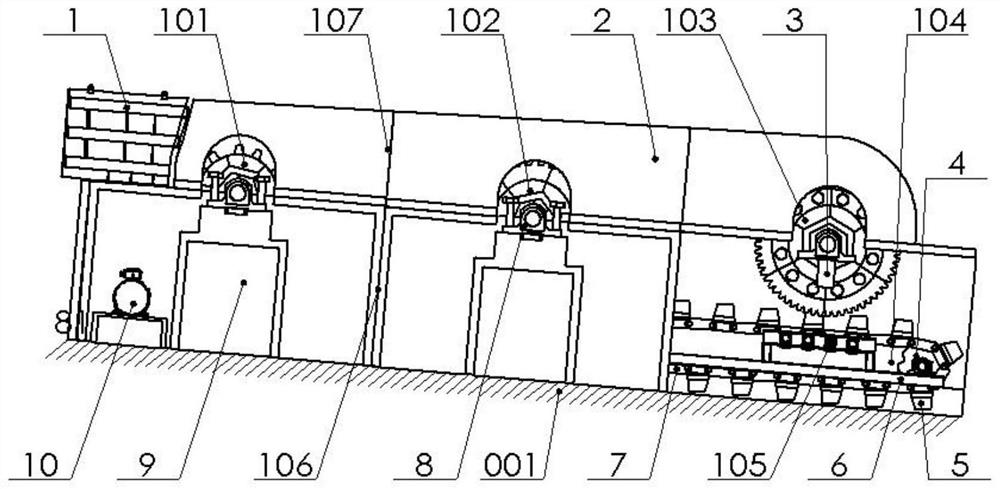

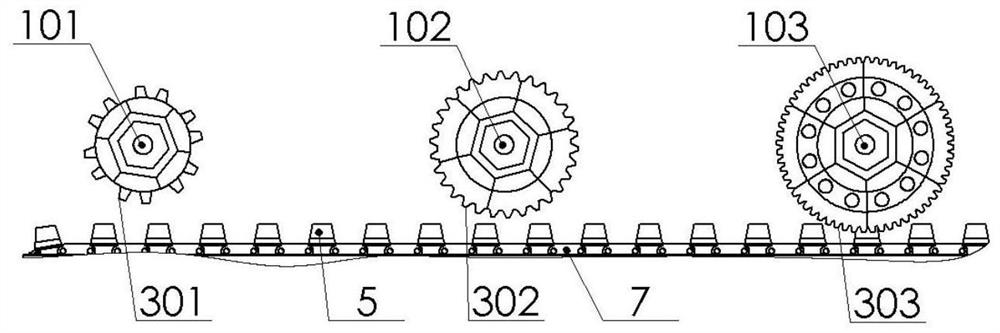

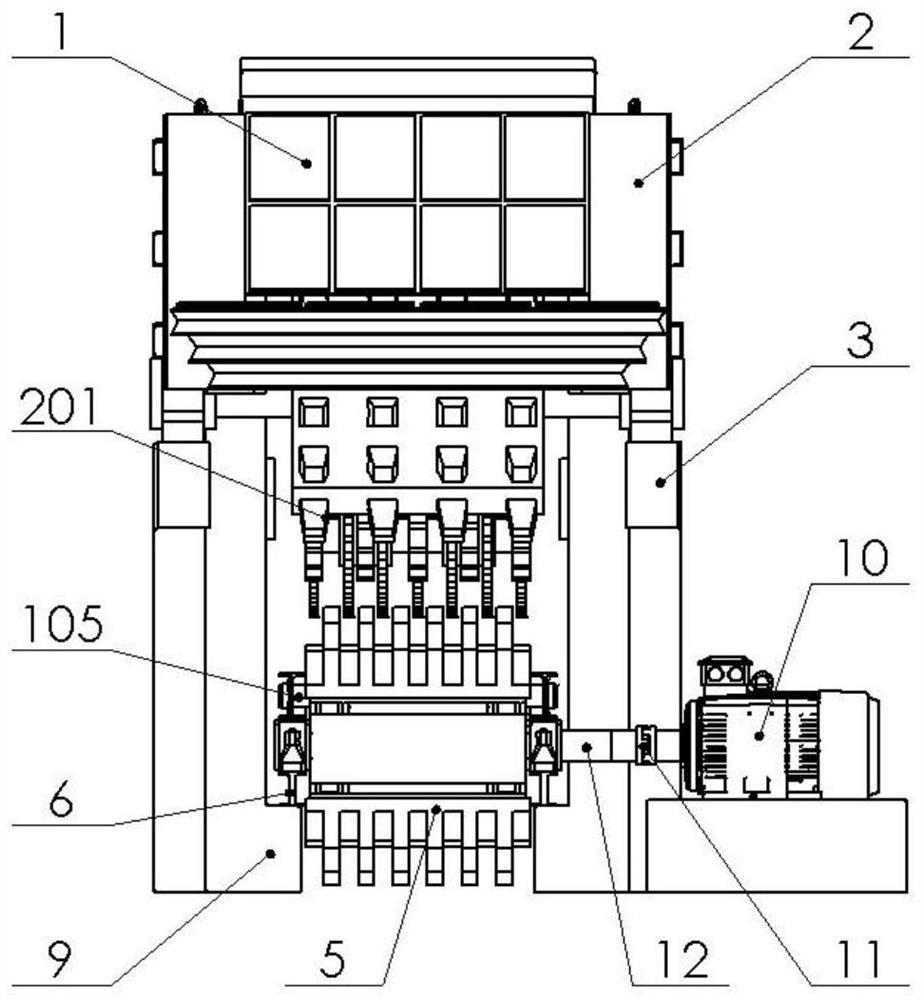

[0022] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a plate-chain compound crusher with adjustable crushing ratio includes a lower body 106, an upper body 107, a movable toothed roller 201, a sprocket assembly 104, and a supporting wheel group 105; the movable toothed roller is arranged on the lower On the body 106 , the lower body 106 is equipped with a sprocket assembly 104 inside the lower body, the sprocket assembly 107 is provided with a supporting wheel set 105 inside, and the upper body 107 is installed on the lower body 106 . The sprocket assembly 104 includes a plate chain 7, a driving wheel 4 and a block 5. The plate chain 7 is engaged with the driving wheel 4, and the driving wheel 4 is connected to the transmission shaft 12, which is connected to the coupling 11, and the coupling 11 is connected to the motor. 10. The power of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com