Adjustable T-shaped connector conveyor for electricity

A technology for conveyors and connectors, which is applied in the field of adjustable T-connector conveyors for electrical applications, and can solve the problems that the matching conveyor cannot be used for a variety of products, cost waste, and inconvenient positioning of belt lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

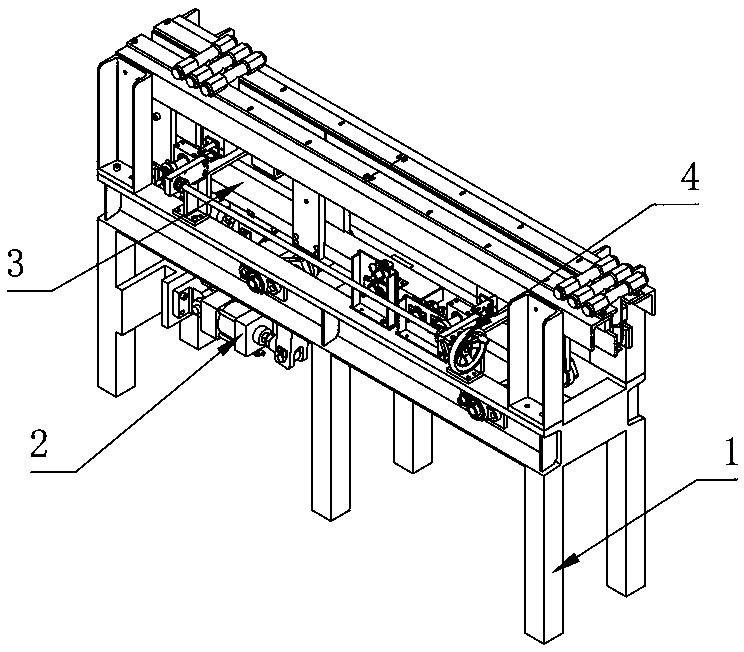

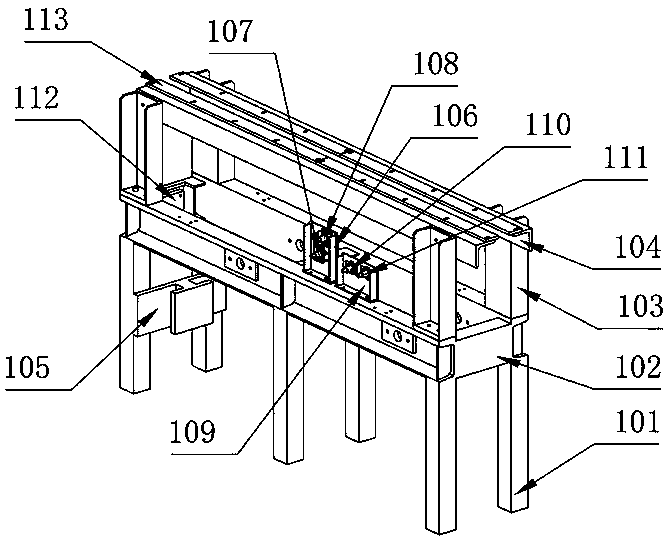

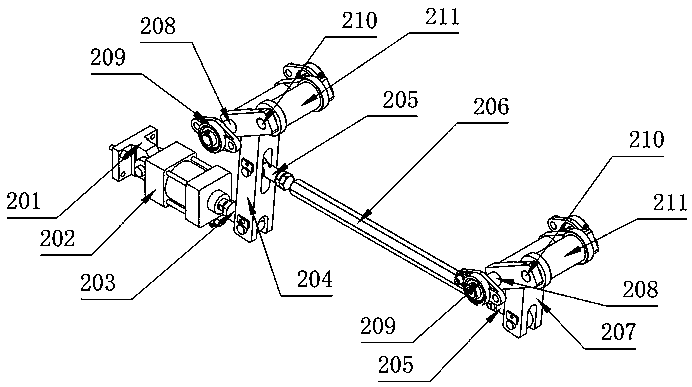

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A conveyor with adjustable T-connectors for electrical use is shown.

[0025] Specific as figure 1 and 2 As shown, the lifting device 2, the moving device 3 and the adjusting device 4 are installed on the conveyor frame 1, and the conveyor frame 1 includes frame legs 101, frame horizontal frames 102, and Column 103, frame upper beam 104, lifting device mounting frame 105, vertical sensor mounting frame 106, lower sensor 107, upper sensor 108, horizontal sensor mounting frame 109, proximal sensor 110, remote sensor device 111, mobile device mounting frame 112 and parts placement plate 113, the rack legs 101 are arranged as multiple groups of vertically symmetrical placements, the upper ends of the rack legs 101 are fixedly connected with a frame horizontal frame 102, the machine The upper end of the rack frame 102 is fixedly connected with a plurality of rack upper columns 103, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com