Environment-friendly recovery device for cement boards for building construction

A technology for building construction and recycling devices, which is applied in the directions of transportation and packaging, solid waste removal, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

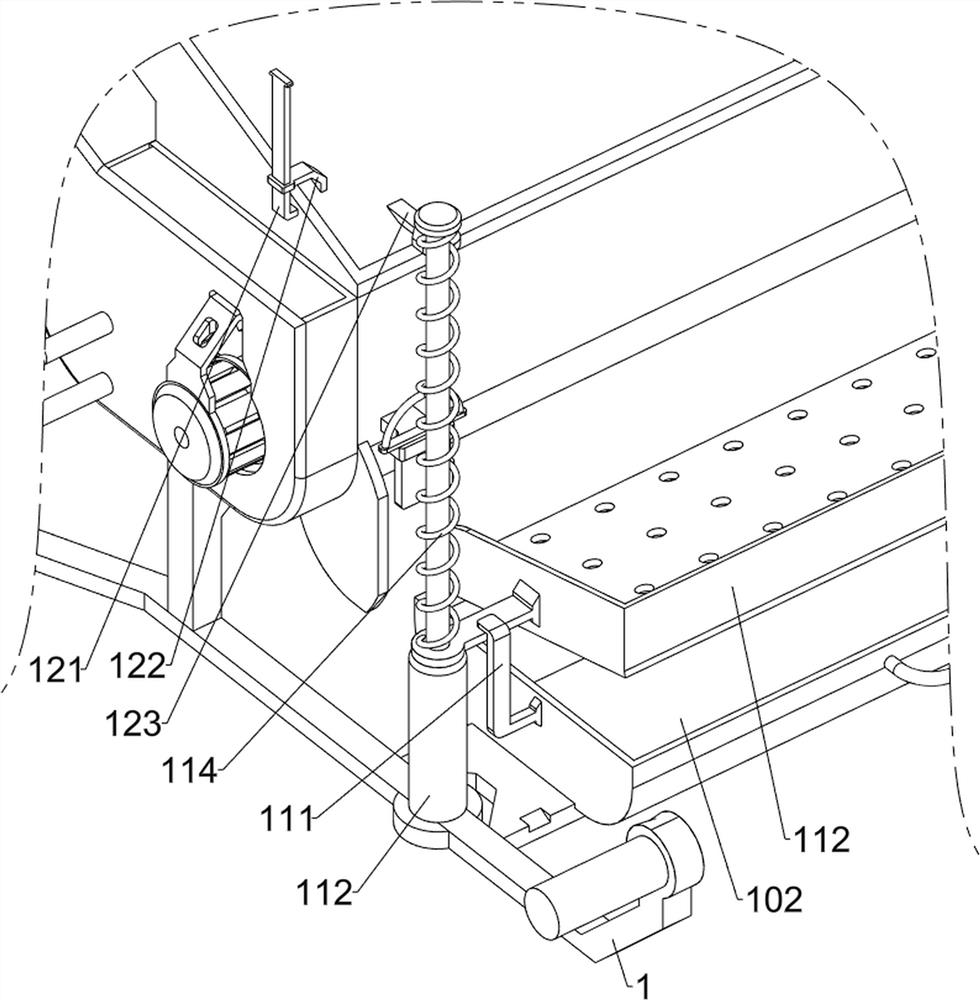

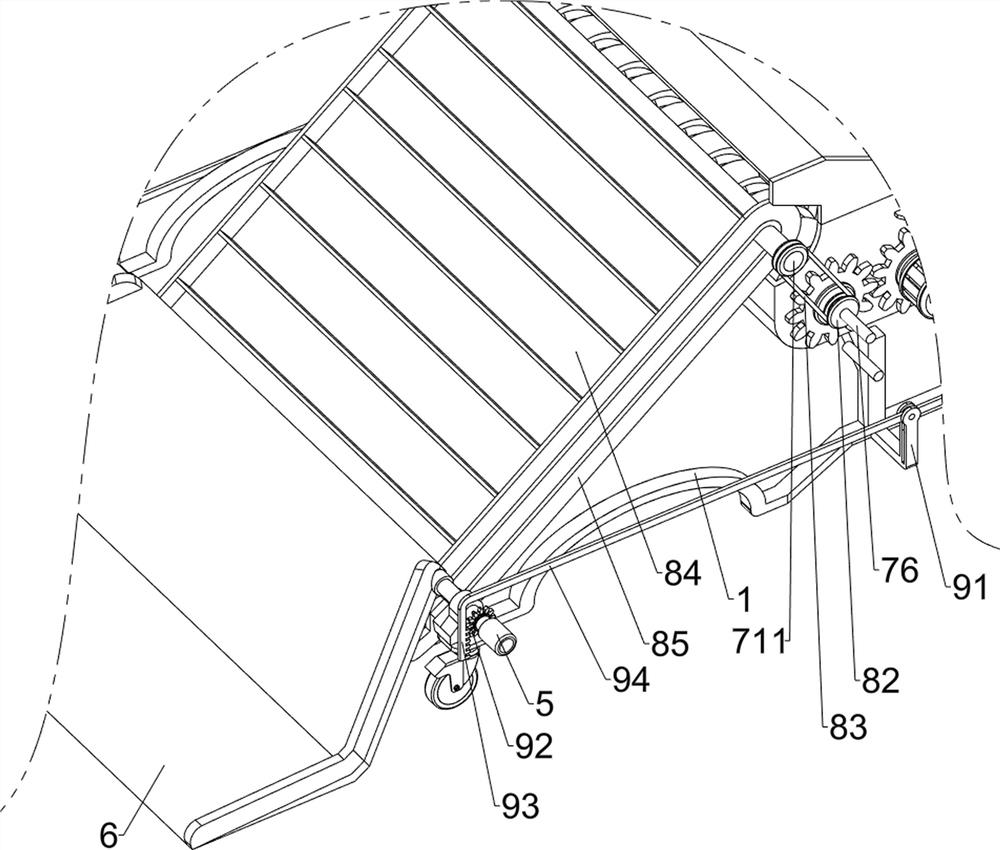

[0036] An environmentally friendly recycling device for cement boards used in building construction, such as figure 1 and figure 2 As shown, it includes a fixing frame 1, a runner 2, a handle 3, a universal wheel 4, a first connecting shaft 5, a push plate 6, a crushing mechanism 7 and a conveying mechanism 8. The fixing frame 1 is provided with two, two The fixing frames are arranged on the left and right sides. The rear sides of the two fixing frames 1 are connected with the runner 2 in a rotatable manner. A universal wheel 4 is rotatably installed at the bottom, a first connecting shaft 5 is rotatably connected between the upper parts of the front sides of the two fixing frames 1, and a push plate 6 is connected to the first connecting shaft 5 by welding. 1 is provided with a crushing mechanism 7, and the crushing mechanism 7 is provided with a conveying mechanism 8.

[0037] like figure 2 , image 3 , Figure 4 and Image 6 As shown, the crushing mechanism 7 includ...

Embodiment 2

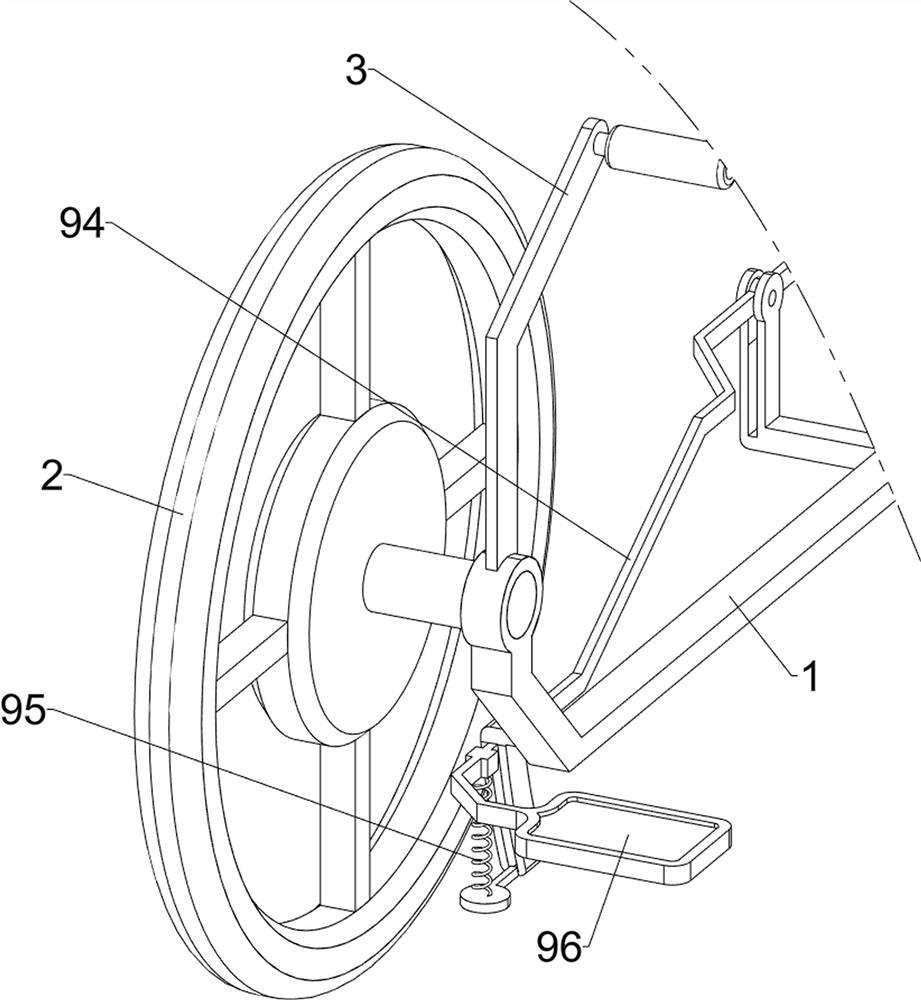

[0041] On the basis of Example 1, as figure 1 , Image 6 and Figure 7 As shown, it also includes a pedal mechanism 9, the pedal mechanism 9 includes a support block 91, a second spur gear 92, a rack 93, a connecting rod 94, a first spring 95 and a pedal 96, and the two fixed frames 1 are far away from each other A support block 91 is connected to one side of the support block 91 by means of bolt connection, and the left and right sides of the first connecting shaft 5 are connected to a second spur gear 92 by means of interference connection. The front side of the rod 94 is connected with a rack 93 by welding, the rack 93 is engaged with the second spur gear 92, the rear side of the connecting rod 94 is connected with a pedal 96, and the rear side of the connecting rod 94 can slide on the rear side of the fixing frame 1, A first spring 95 is connected between the pedal 96 and the rear side of the fixing frame 1 .

[0042] When it is necessary to twist the first connecting s...

Embodiment 3

[0046] On the basis of Example 2, as figure 1 , Figure 8 and Figure 9 As shown, it also includes a screening mechanism 11, the screening mechanism 11 includes a clamping rod 111, a guide rod 112, a sieve plate 113 and a second spring 114, and the upper parts of the left and right sides of the second fixing frame 102 are connected by welding. Rod 111, guide rods 112 are connected on the left and right sides of the top of the fixing frame 1, and a sieve plate 113 is slidably connected between the two guide rods 112. Above the frame 102 , the upper parts of the two guide rods 112 are sleeved with second springs 114 , and the two ends of the second springs 114 are respectively connected to the upper part of the guide rods 112 and the top of the screen plate 113 .

[0047] When the clamping rod 111 clamps the sieve plate 113, the second spring 114 is in a stretched state. When the arc baffle 710 swings down along the hinge point under the action of gravity, the crushed cement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com