Damage detection method, device, equipment, storage medium and damage detector

A damage detection and detector technology, applied in the fields of equipment, devices, damage detection methods, computer-readable storage media and damage detectors, can solve the problems of potential safety hazards, heavy maintenance workload and high cost of traction steel belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

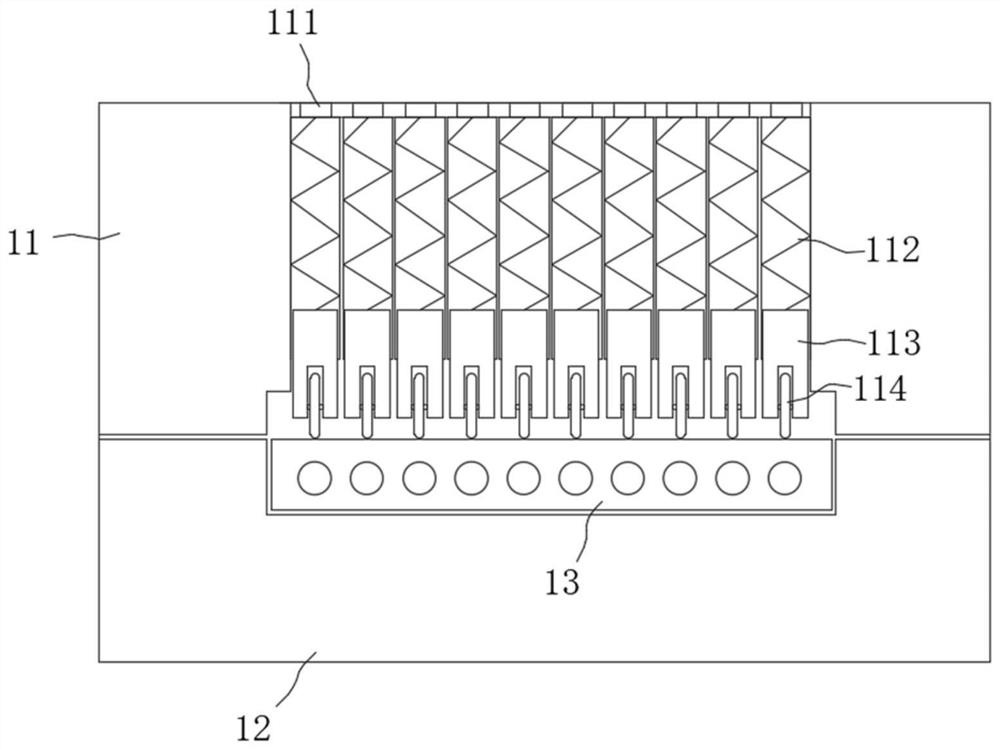

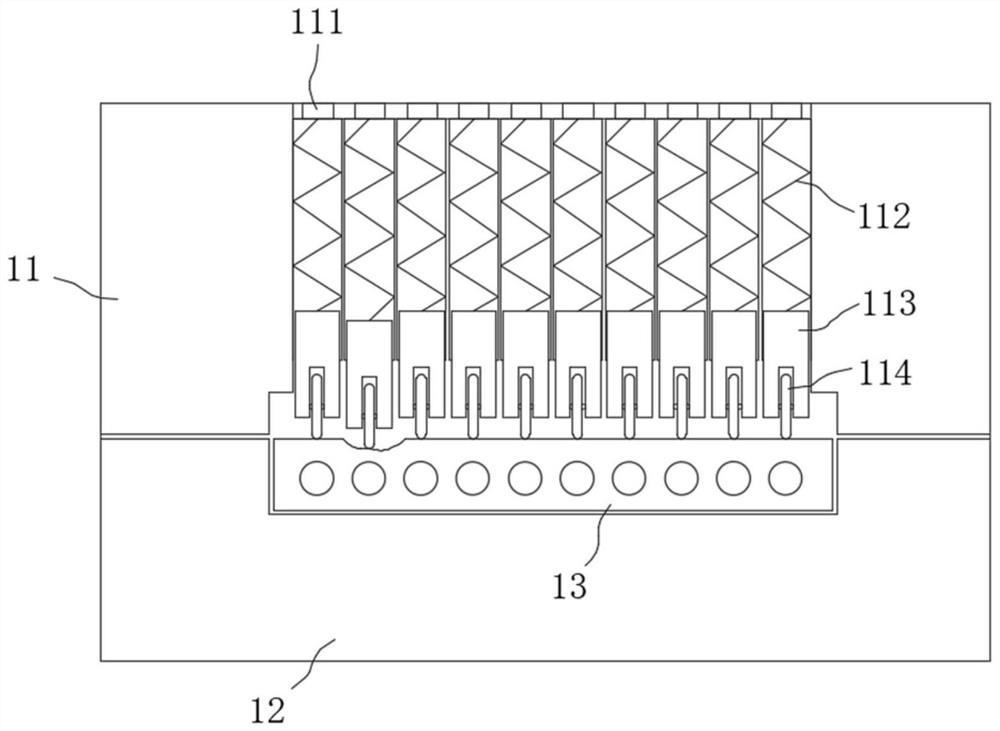

[0037] figure 1 A structural diagram of the damage detector provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the state of the damage detector provided in Embodiment 1 of the present invention when it detects damage to the surface protection layer. This embodiment is applicable to the damage detection of the surface protection layer of the elevator traction steel belt, specifically including the pressure sensor 111, the elastic component and the base 11, the pressure sensor 111 and the elastic component are installed in the base 11, and the elastic component is far away from the pressure sensor One end of 111 exceeds the surface of the base 11; the elastic member can abut against the target steel belt 13 and be squeezed and compressed, and the pressure sensor 111 is used to collect the pressure value generated by the elastic member being squeezed by the target steel belt 13, the pressure value Used for damage detection on the target pro...

Embodiment 2

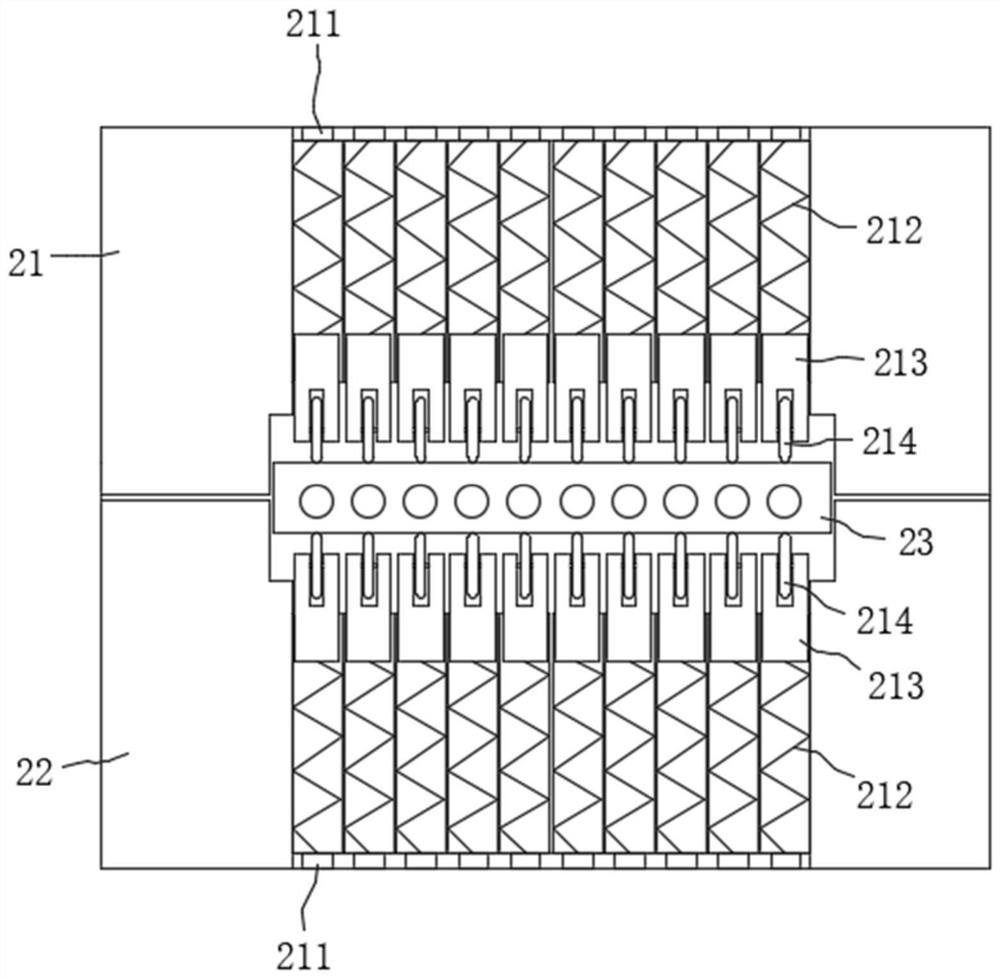

[0055] image 3 The structural diagram of a damage detector provided by Embodiment 2 of the present invention. This embodiment is embodied on the basis of the above embodiments. The damage detector includes a pressure sensor 211, an elastic component, a first base 21 and The second base 22, the first base 21 and the second base 22 are detachably connected, and a pressure sensor 211 and an elastic member are installed in the first base 21 and the second base 22, and the first base 21 The side on which the pressure sensor 211 and the elastic component are installed is opposite to the side on which the pressure sensor 211 and the elastic component are installed on the second base 22 . When the first base 21 is combined with the second base 22, the elastic parts provided in the first base 21 and the elastic parts provided in the second base 22 abut against the opposite surfaces of the target steel strip 23, realizing At the same time, the detection of the surface protection layer...

Embodiment 3

[0067] Figure 4 It is a flow chart of the damage detection method provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation where the pressure value detected by the damage detector is used to detect damage to the surface protection layer of the elevator traction steel belt. detection device, the damage detection device can be implemented by hardware and / or software, for example, configured in the damage detector provided in Embodiments 1 and 2, specifically including the following steps:

[0068] S410. Determine that the damage detector is restricted to slide within the specified range of the target steel belt.

[0069] In this embodiment, when the damage detector is limited within the specified range of the target steel strip, and the damage detector is driven to slide on the surface of the target steel strip, the damage detector will detect that the received current state of the damage detector conforms to If required, proceed to the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com