Electromagnetic rivetter

A technology of electromagnetic riveting and electromagnetic riveting gun, which is applied in the field of riveting of difficult-to-form materials and large-diameter rivets, can solve the problems of reducing connection efficiency, increasing structural weight, and low efficiency, so as to improve engineering practicability, improve riveting quality, To avoid the effect of voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

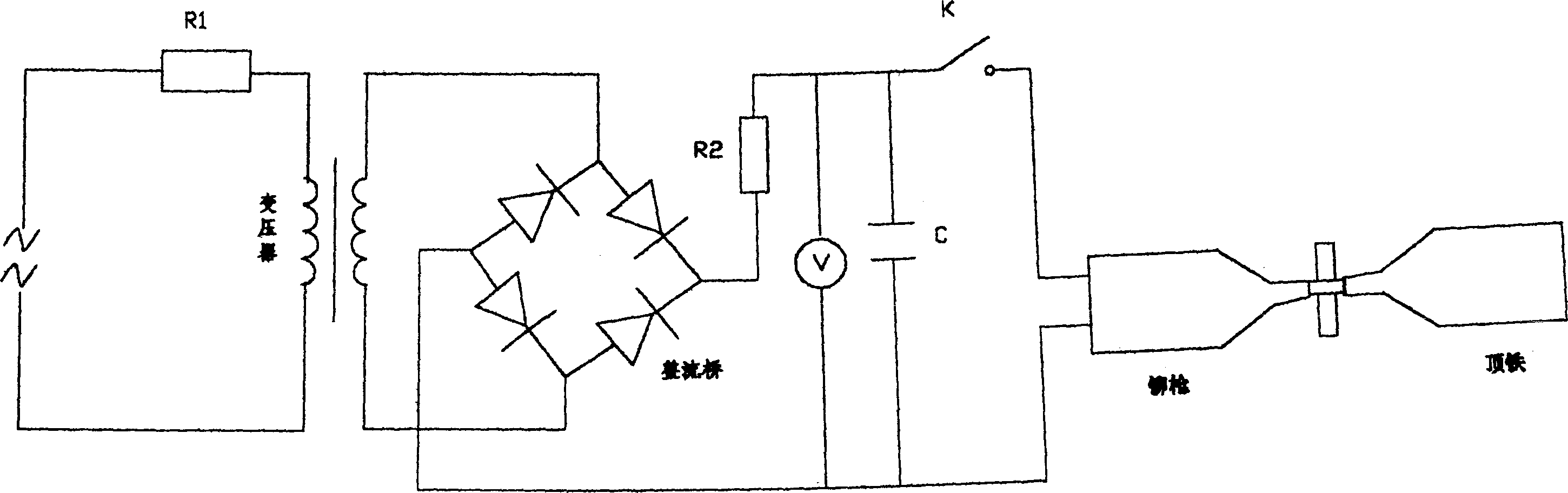

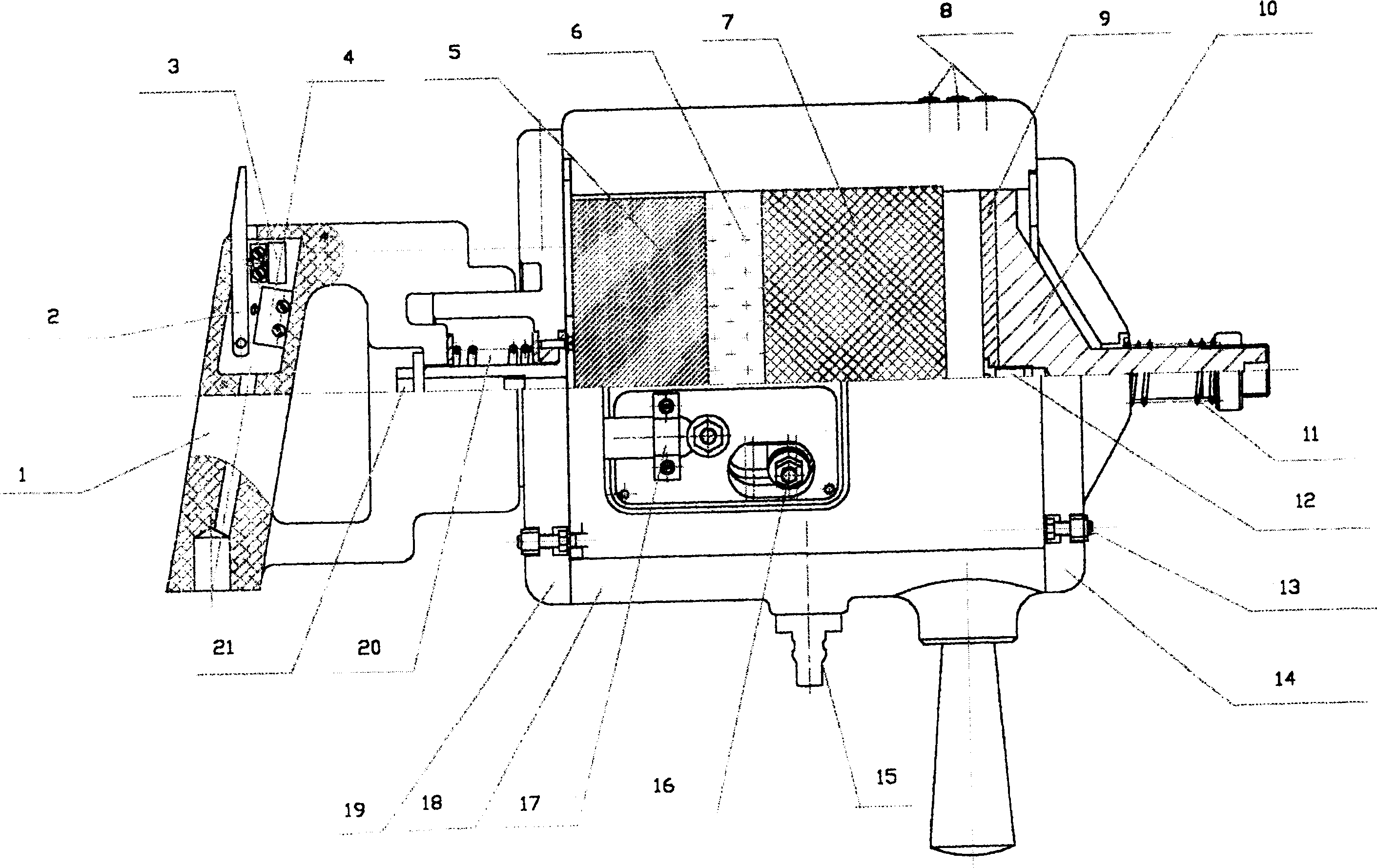

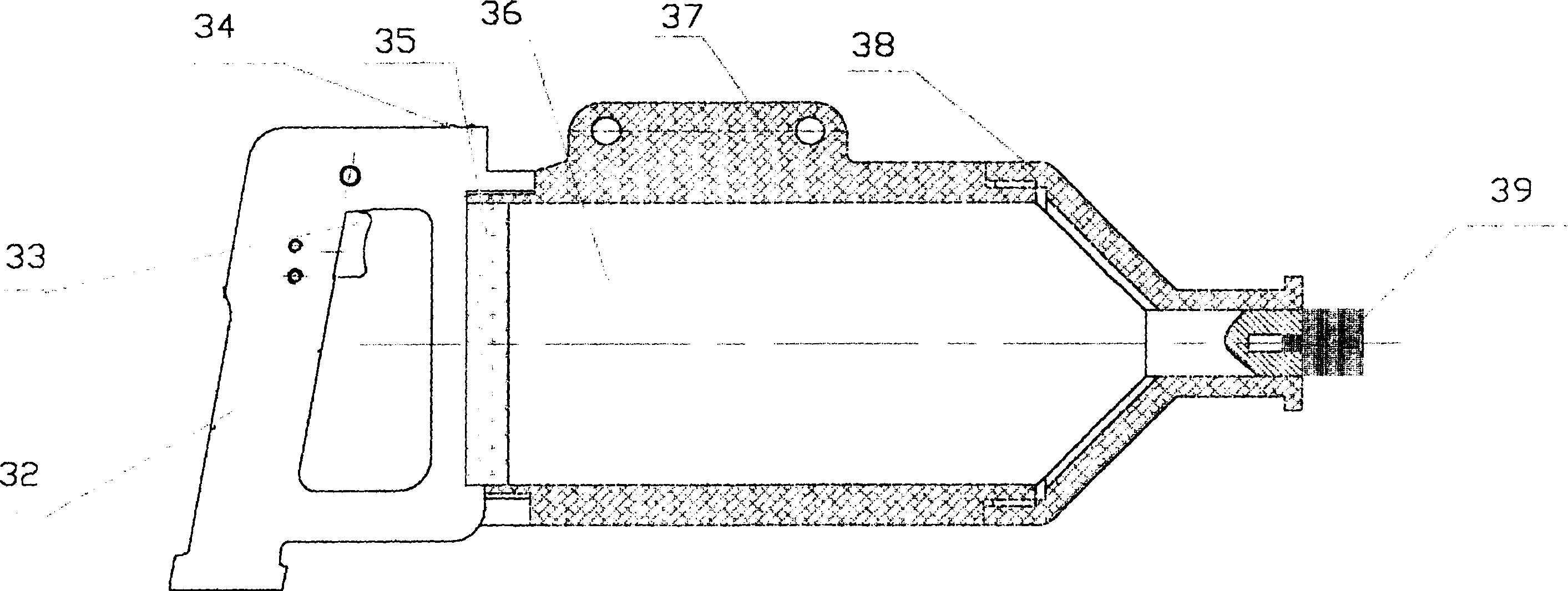

[0023] Electromagnetic riveting equipment is mainly composed of power supply system, riveting gun and top iron. The implementation process is described in detail below.

[0024] The power supply system uses 4 pulse capacitors with a rated voltage of 4000V and a rated capacity of 400 microfarads. The control system is mainly composed of two parts: analog control part and PLC operation loop control. The analog control mainly includes charging voltage control, thyristor trigger control and protection part. The charging voltage is controlled by the PI control method of the voltage loop to realize the real-time supplement of the voltage and avoid the voltage drop of the capacitor caused by the working current of the Hall sensor. Charging control includes two parts: voltage real-time measurement and voltage comparison. When the voltage of the measured capacitor is lower than the set voltage, the charging signal is input to the thyristor to continue charging; when the voltage reach...

Embodiment 2

[0032] Electromagnetic riveting equipment is mainly composed of power supply system, riveting gun and top iron. The implementation process is described in detail below.

[0033]The power supply system uses 6 pulse capacitors with a rated voltage of 4000V and a rated capacity of 400 microfarads. The control system is mainly composed of two parts: analog control part and PLC operation loop control. The analog control mainly includes charging voltage control, thyristor trigger control and protection part. The charging voltage is controlled by the PI control method of the voltage loop to realize the real-time supplement of the voltage and avoid the voltage drop of the capacitor caused by the working current of the Hall sensor. Charging control includes two parts: voltage real-time measurement and voltage comparison. When the voltage of the measured capacitor is lower than the set voltage, the charging signal is input to the thyristor to continue charging; when the voltage reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com