Skeleton leveling tile laying construction method

A construction method and ceramic tile technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of increasing the weight of the building structure, not meeting the needs of social development, and the amount of solid waste in construction, and achieving easy control of the laying quality. , The characteristics of commercial services are obvious, and the effect of improving the utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

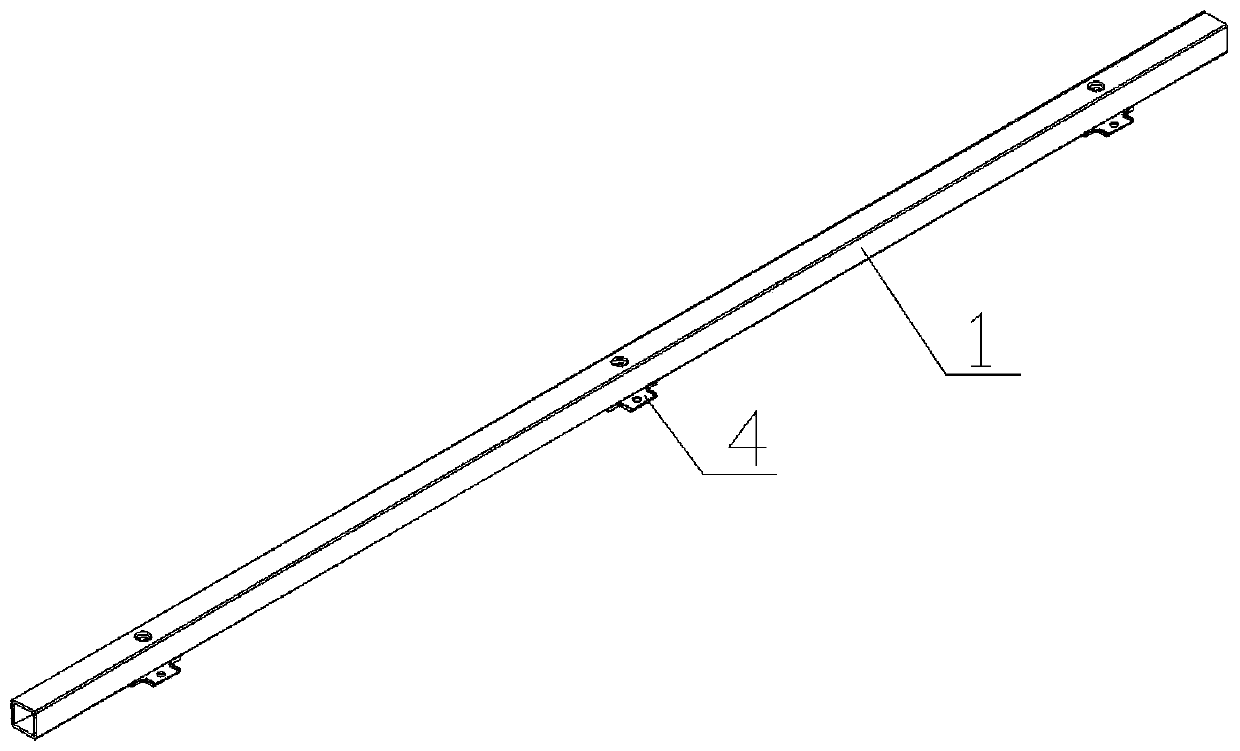

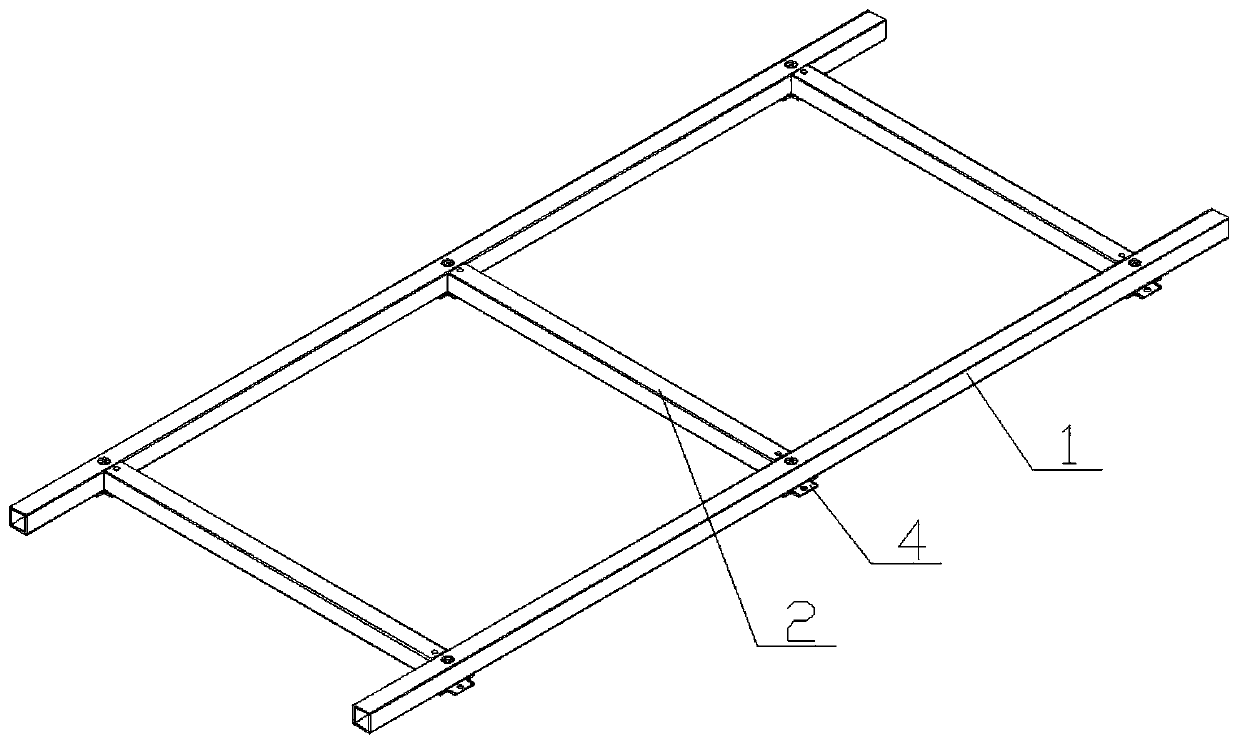

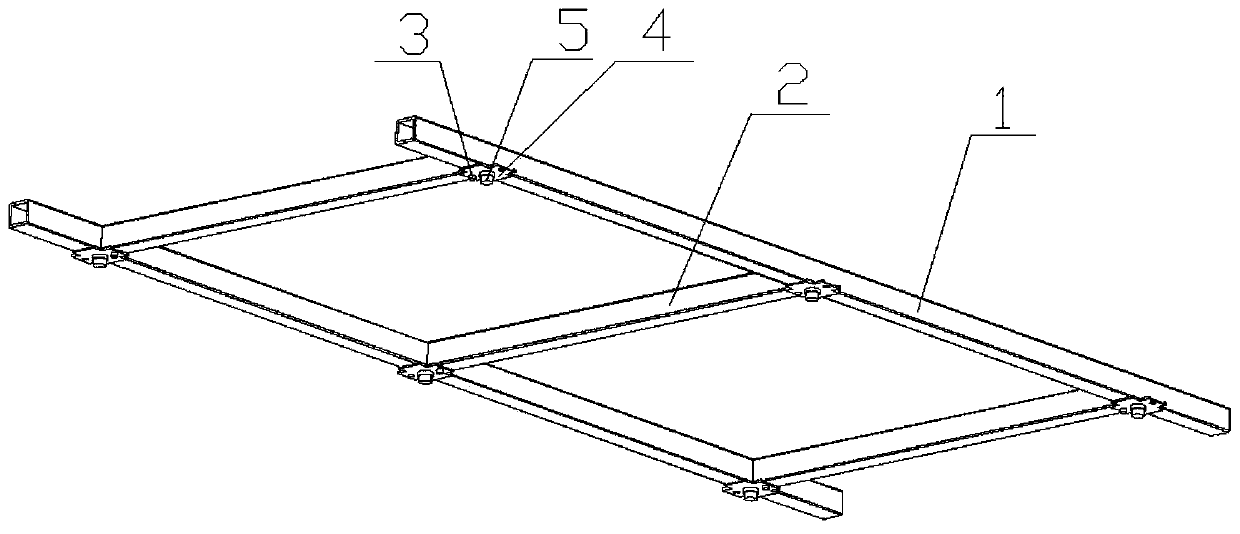

[0035] Such as Figure 1-12 Shown is a specific embodiment of the construction method for laying skeleton leveling tiles of the present invention, comprising the following steps:

[0036] Step 1. Lay the keel. According to the construction environment and the size of the tiles, install the overall steel square tube keel within the entire area where tiles need to be laid. The keel is connected by cross connectors and can be leveled by cross connectors. The connecting piece connects the keel to make a square or rectangular frame structure, ensuring that the four corners of the tiles can fall on the 1 / 2 position of the upper surface of the keel laid, and the gap between the tiles near the wall is covered by the skirting board;

[0037] Step 2. Leveling the keel. Find the highest point of the intersection point after the keel falls to the ground. Use this as the base point for level adjustment. Adjust the overall keel level on the cross connector of the keel. The sequence of verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com