Rock crushing and heading machine

A roadheader and rock technology, which is applied in slitting machinery, open-pit mining, earthwork drilling and mining, etc. It can solve problems such as locking pins stuck, affecting the swing pressure and inertial force of chisel claws, and damage to rock processing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

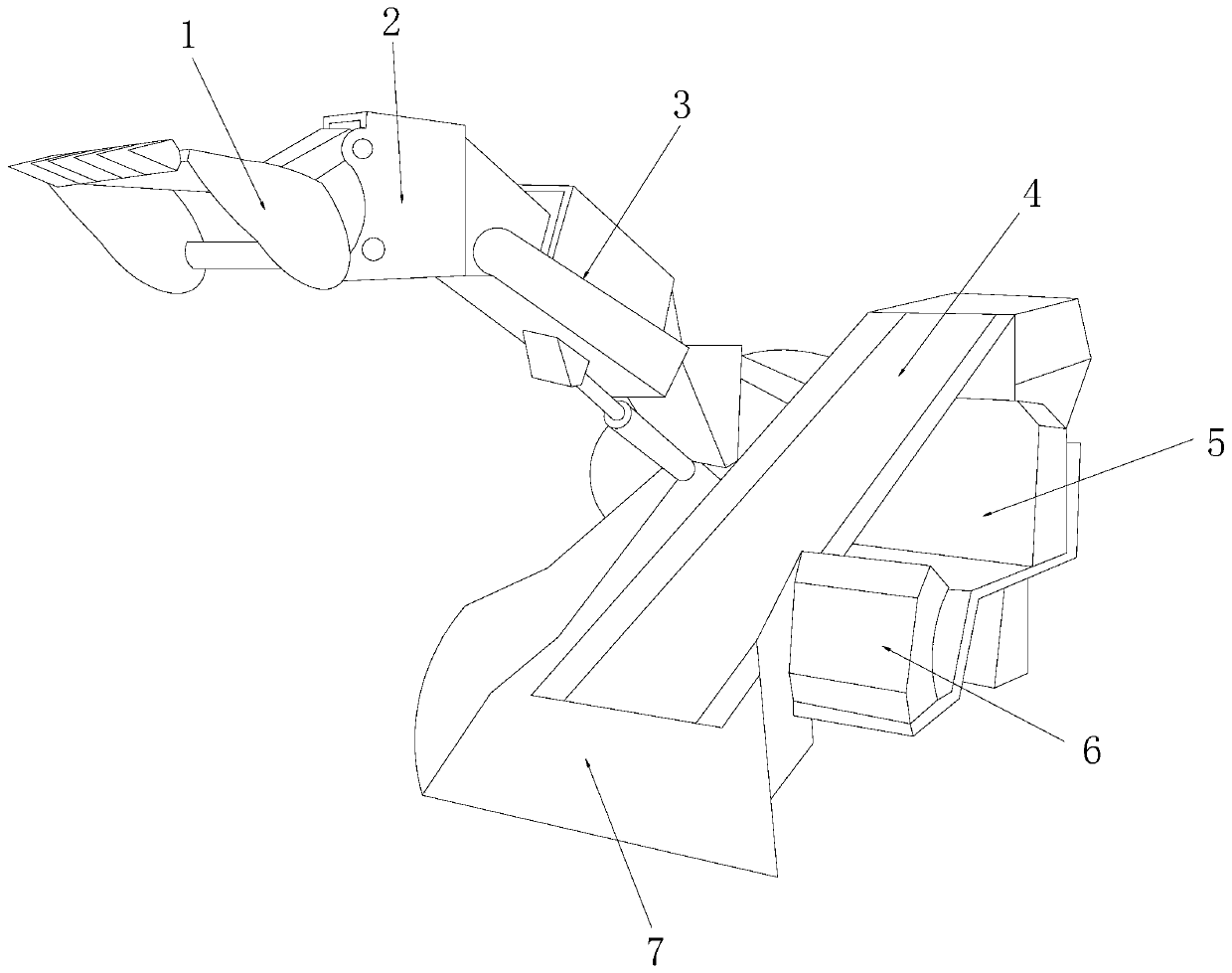

[0032] see Figure 1-Figure 6, The present invention provides a rock crushing roadheader, the structure of which includes: a crushing shovel excavation cap 1, a boom column block 2, a pressure rod pushing machine base 3, a conveyor belt support platform 4, a control room base 5, and a dash panel 6 1. Bucket discharge trough 7, the push rod extension machine base 3 is nested on the right side of the boom column block 2 and is on the same vertical plane, and the crushing and shoveling cap 1 is inserted into the boom column block 2 on the left side and on the same horizontal plane, the push rod extension machine base 3 is installed on the upper left corner of the conveyor belt platform 4, and the bucket discharge chute 7 is nested under the bottom of the conveyor belt platform 4 and is on the same level. On the inclined plane, the dash board 6 is closely attached to the front side of the control room base 5, and the control room base 5 is installed under the bottom of the conveyo...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of rock crushing roadheader, other respects are identical with embodiment 1, and difference is:

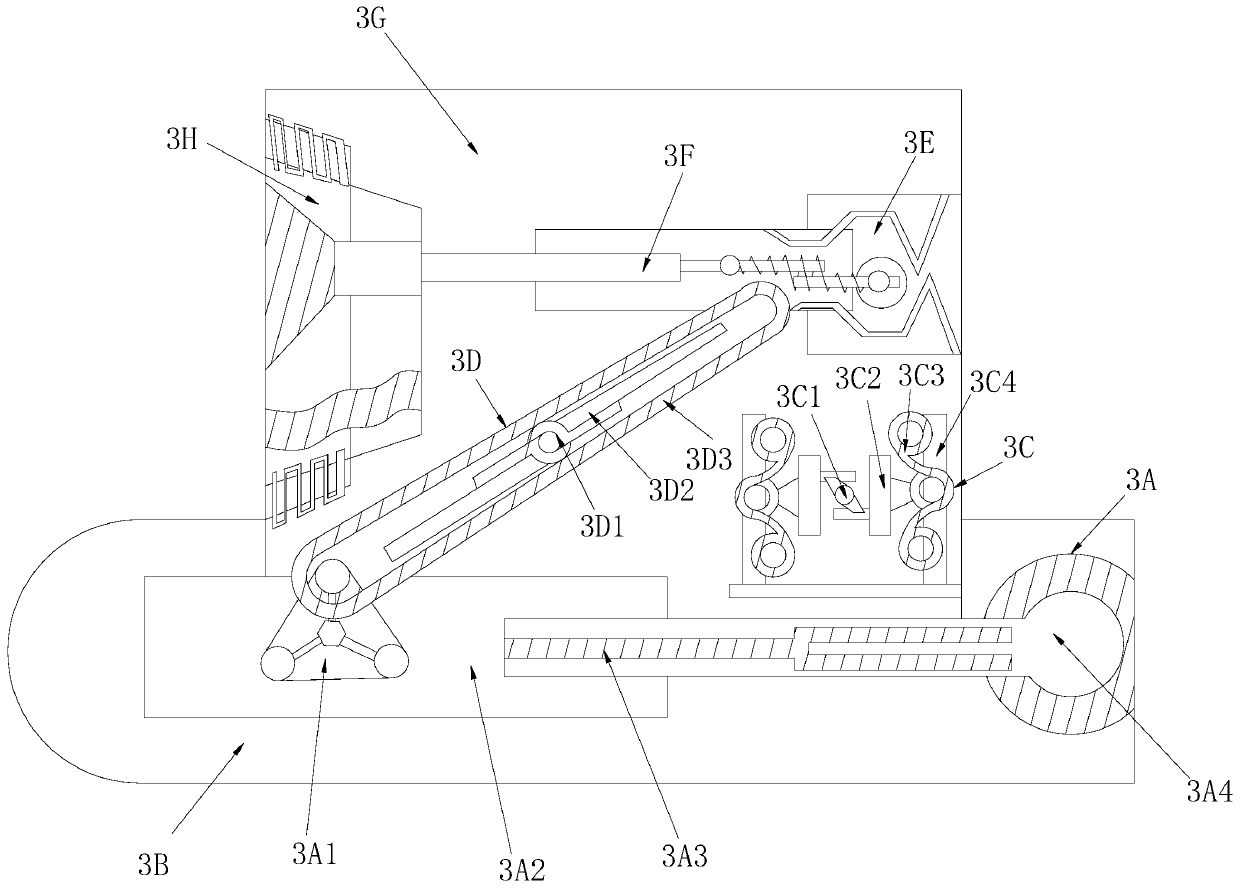

[0040] see figure 2 , the hydraulic cylinder frame groove 3A is composed of a triangular wheel frame plate 3A1, a hydraulic cylinder 3A2, a plunger rod 3A3, and a pneumatic ball cylinder 3A4. The triangular wheel frame plate 3A1 is installed inside the hydraulic cylinder 3A2, and the hydraulic cylinder 3A2 The pneumatic ball cylinder 3A4 is respectively nested on the left and right sides of the plunger rod 3A3 and is on the same horizontal line, and the pneumatic ball cylinder 3A4 pushes the plunger rod 3A3 to push the hydraulic cylinder 3A2 to form a superimposed boosting effect of gas-hydraulic combined pressure, ensuring The impact force of the rock breaking is maximized.

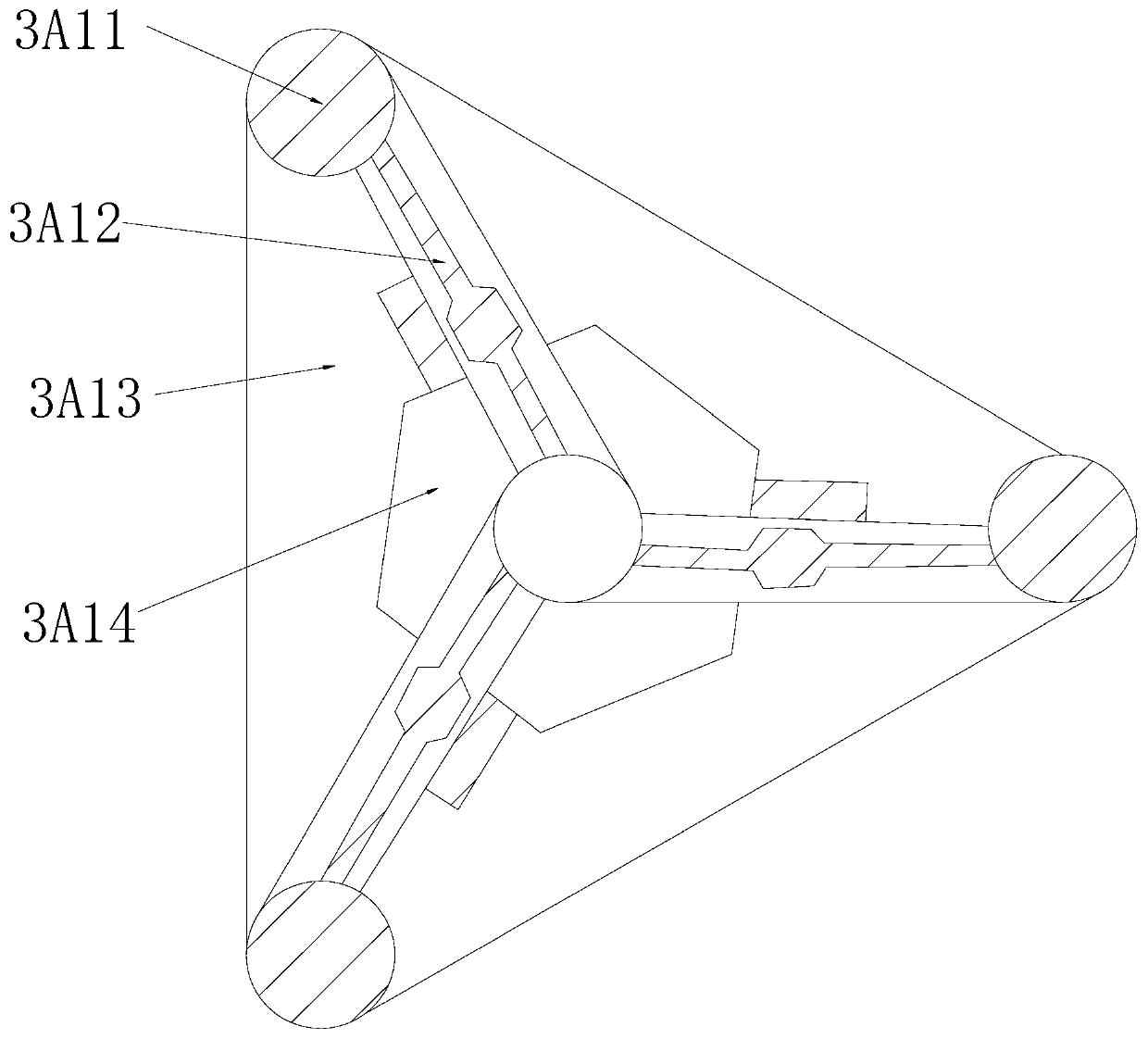

[0041] see image 3 The triangular wheel frame plate 3A1 is composed of a counterweight wheel 3A11, a brace bar 3A12, a triangular tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com