Centrifugal pump semi-open impeller with blade top arrangement clearance channels

A blade tip clearance, semi-open technology, applied to components, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problems of centrifugal pumps such as pressure pulsation, unfavorable performance curve stability, and easy humps , to achieve the effect of suppressing leakage backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in detail below with reference to the accompanying drawings and examples.

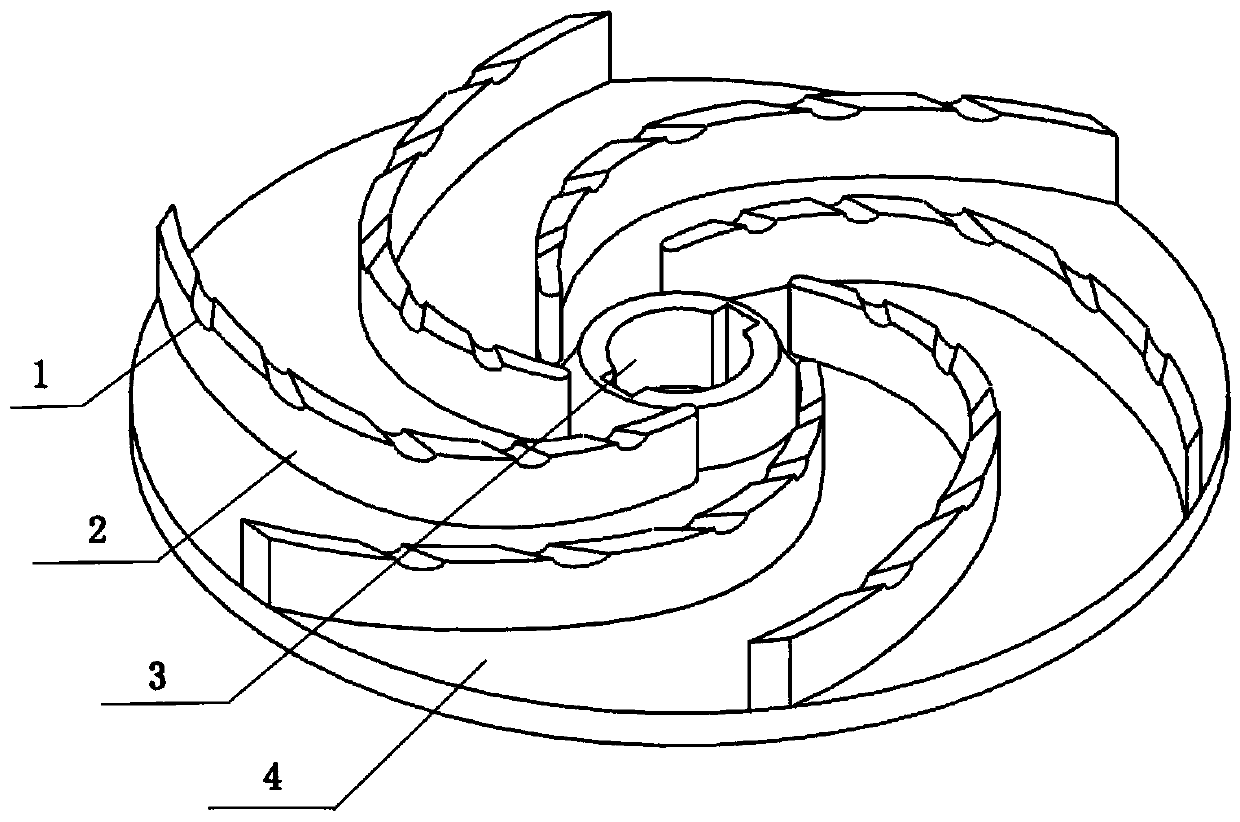

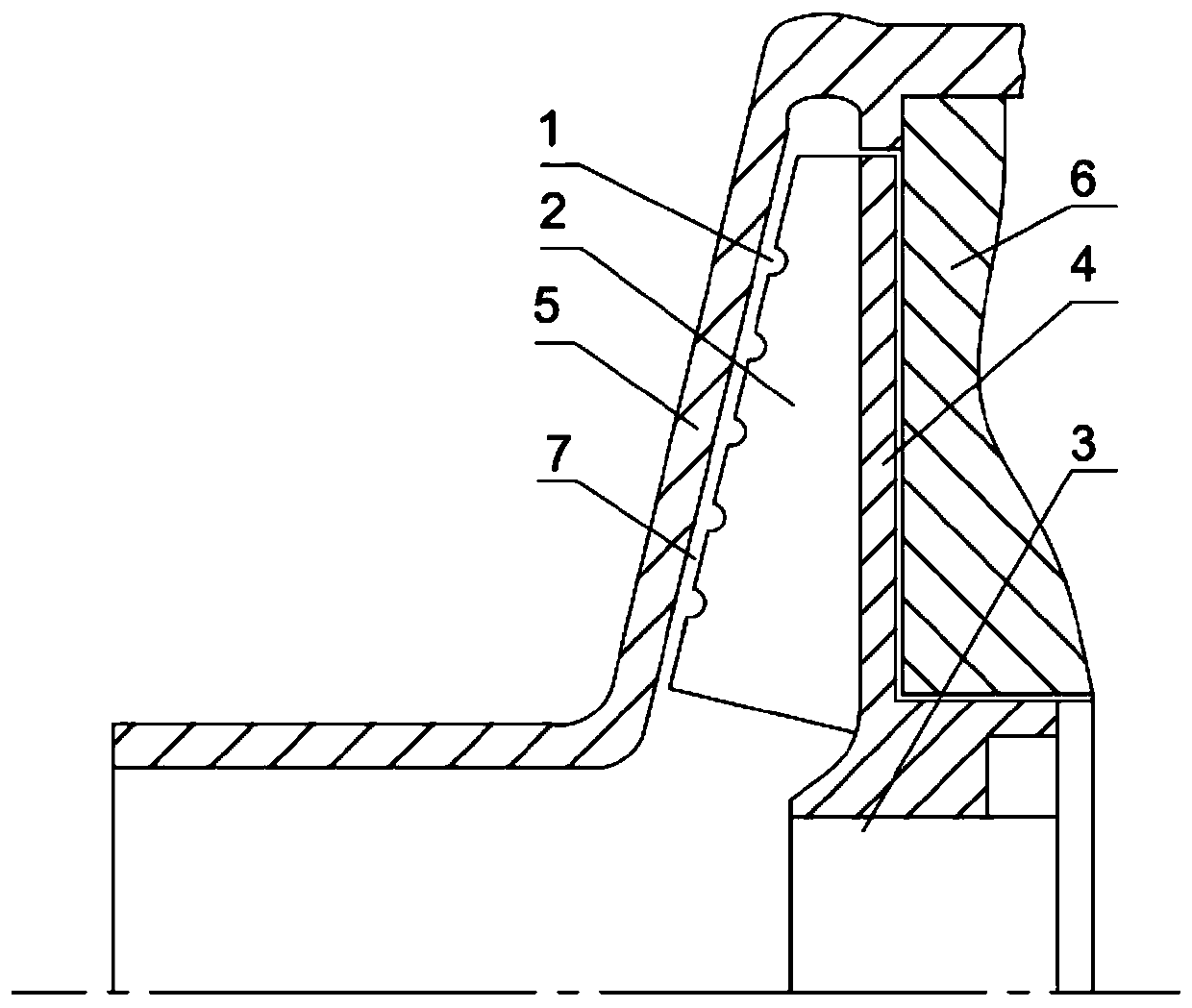

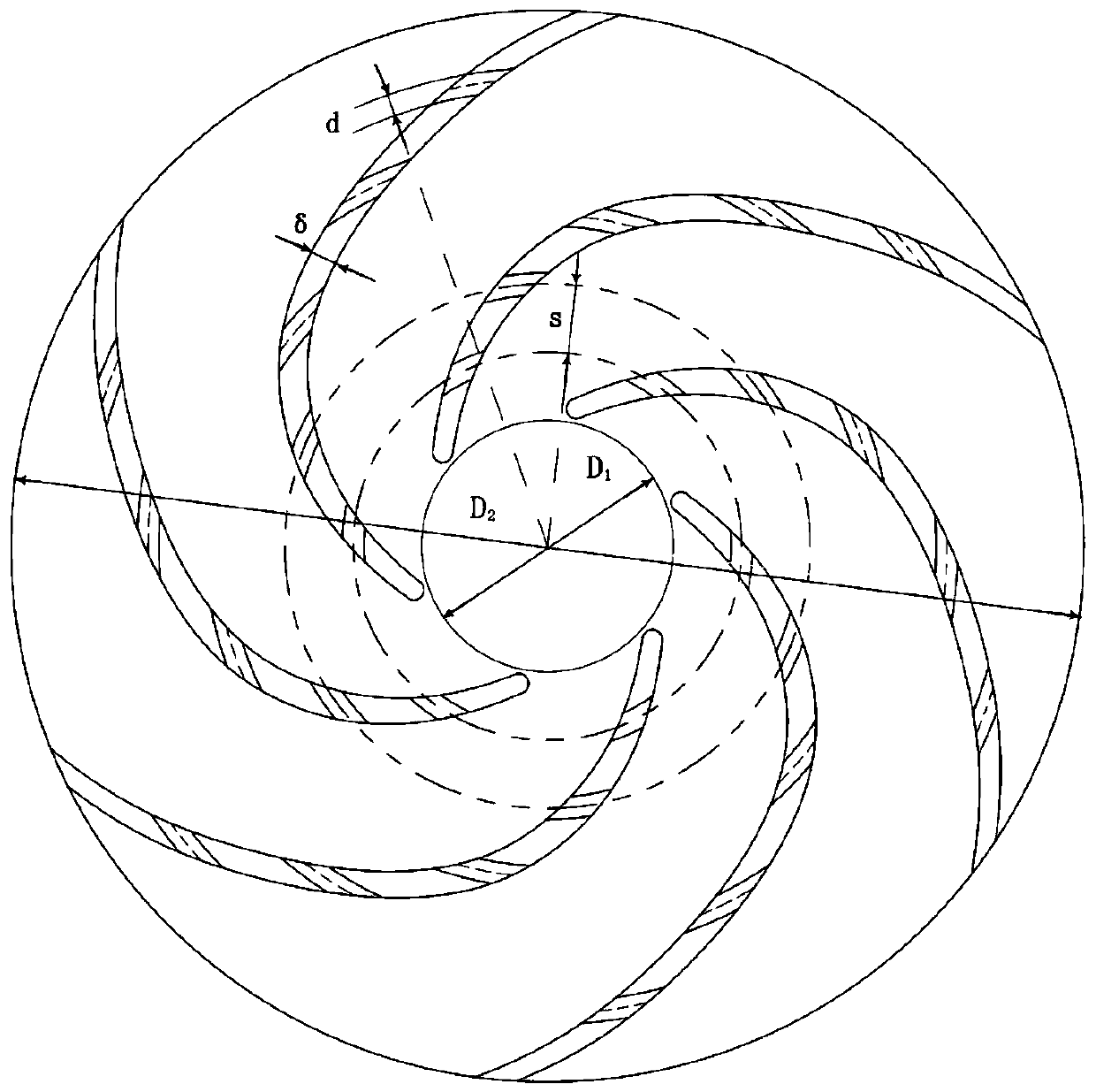

[0026] Such as figure 1 As shown, the specific impeller is located between the pump casing 5 and the pump cover 6. The impeller includes a disc 4 and a plurality of vanes 2. The center of the disc 4 is provided with a shaft hole 3, and the plurality of vanes 2 are arranged along the circumference of the shaft hole 3. The circumferential arrangement is fixed on the end face of the wheel disc 4, and each blade 2 is arranged along a helical segment, the inner end of the blade 2 extends to the side of the shaft hole 3, and the outer end of the blade 2 extends to the edge of the wheel disc 4. figure 2 The fluid enters from the left side of the pump housing 5, passes through the vane 2, and then flows out from the shaft hole 3 of the vane 2 on the other side of the pump cover 6.

[0027] Such as figure 1 and figure 2 As shown, the blade top surface of each blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com