Unpowered pipeline inspection robot with controllable speed

A technology of power pipelines and robots, which is applied to special pipes, pipe components, mechanical equipment, etc., can solve the problems that robots cannot actively control the speed, and achieve the effects of enhancing the ability of active speed control and battery life, saving costs, and increasing the detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

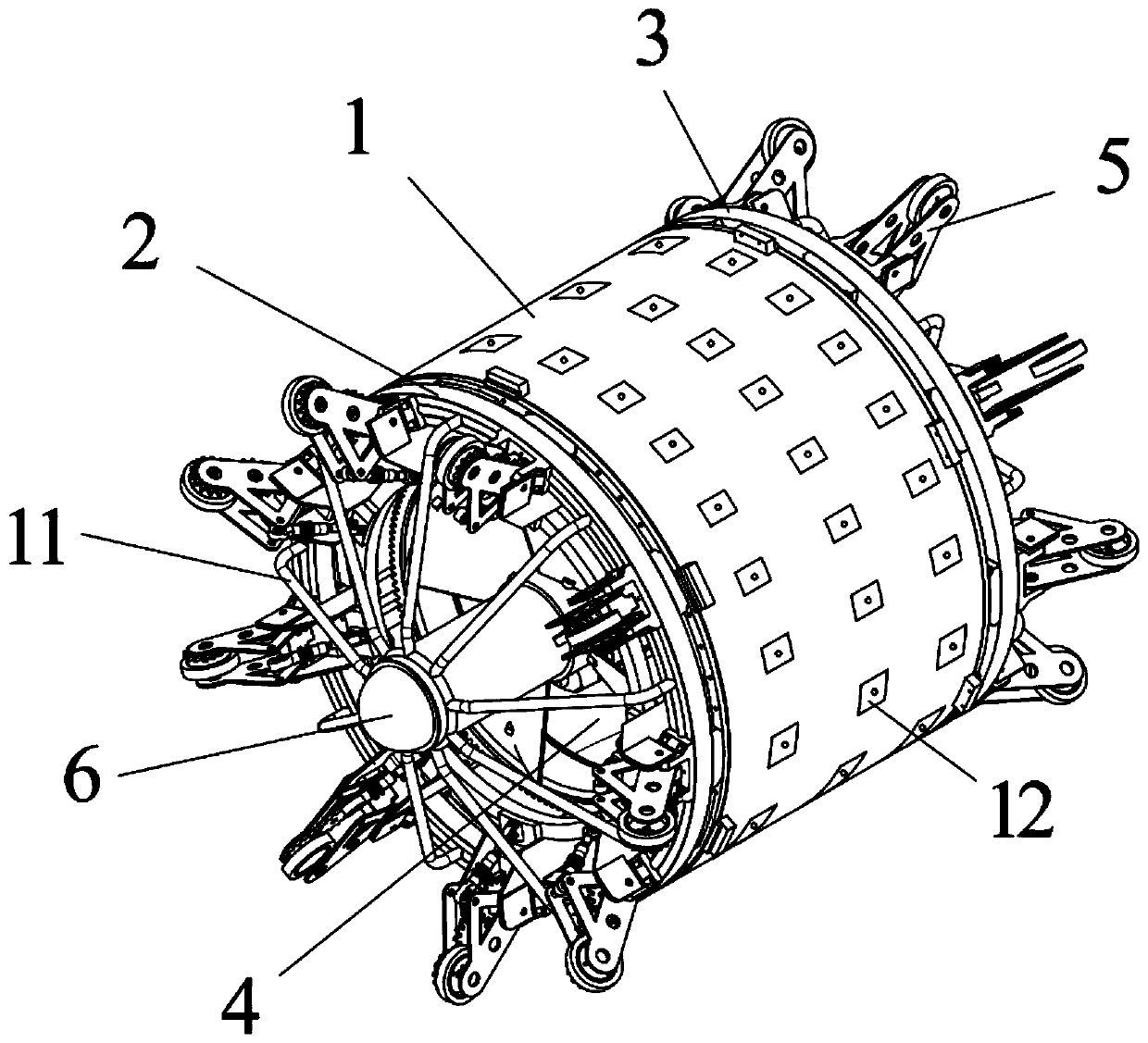

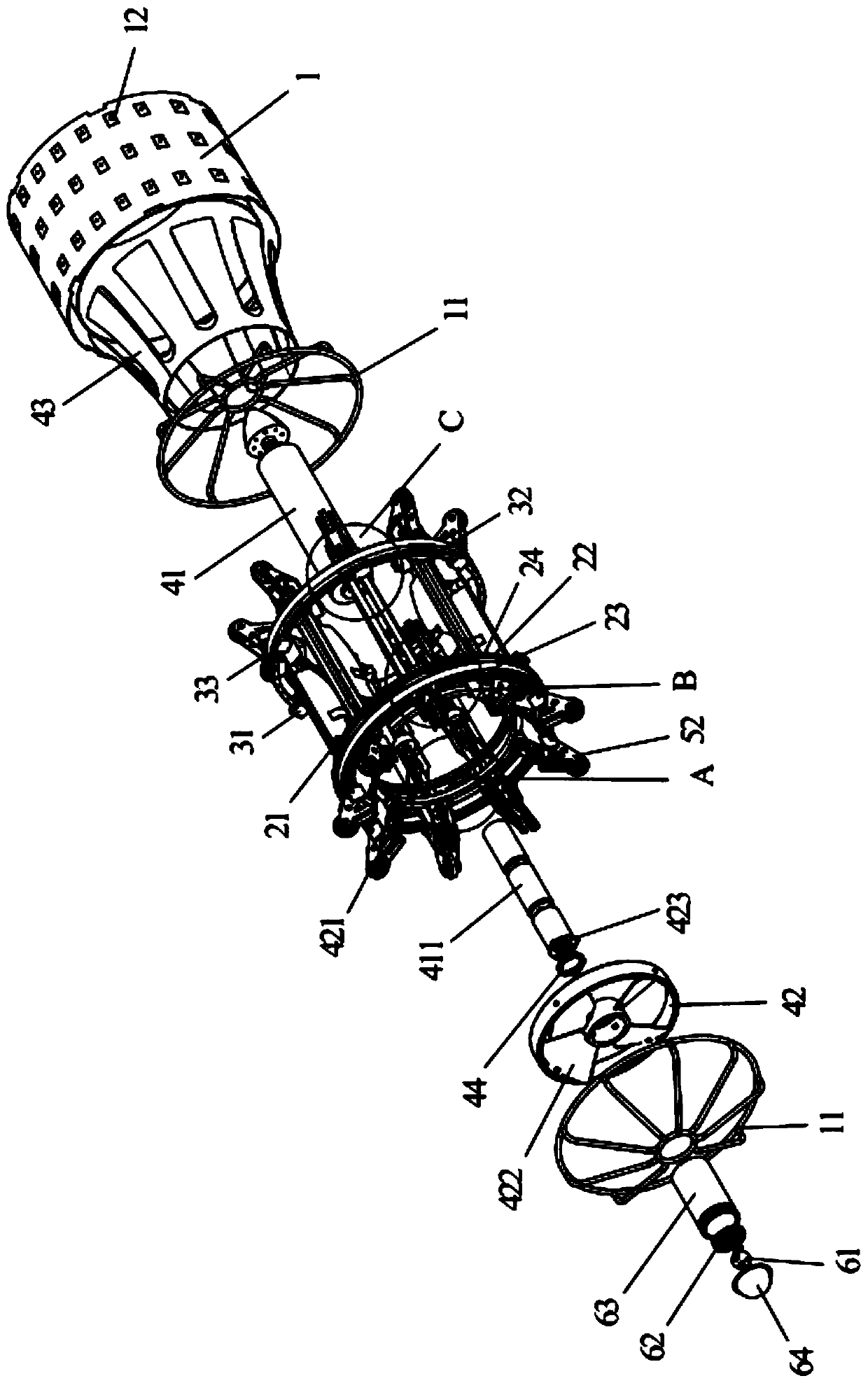

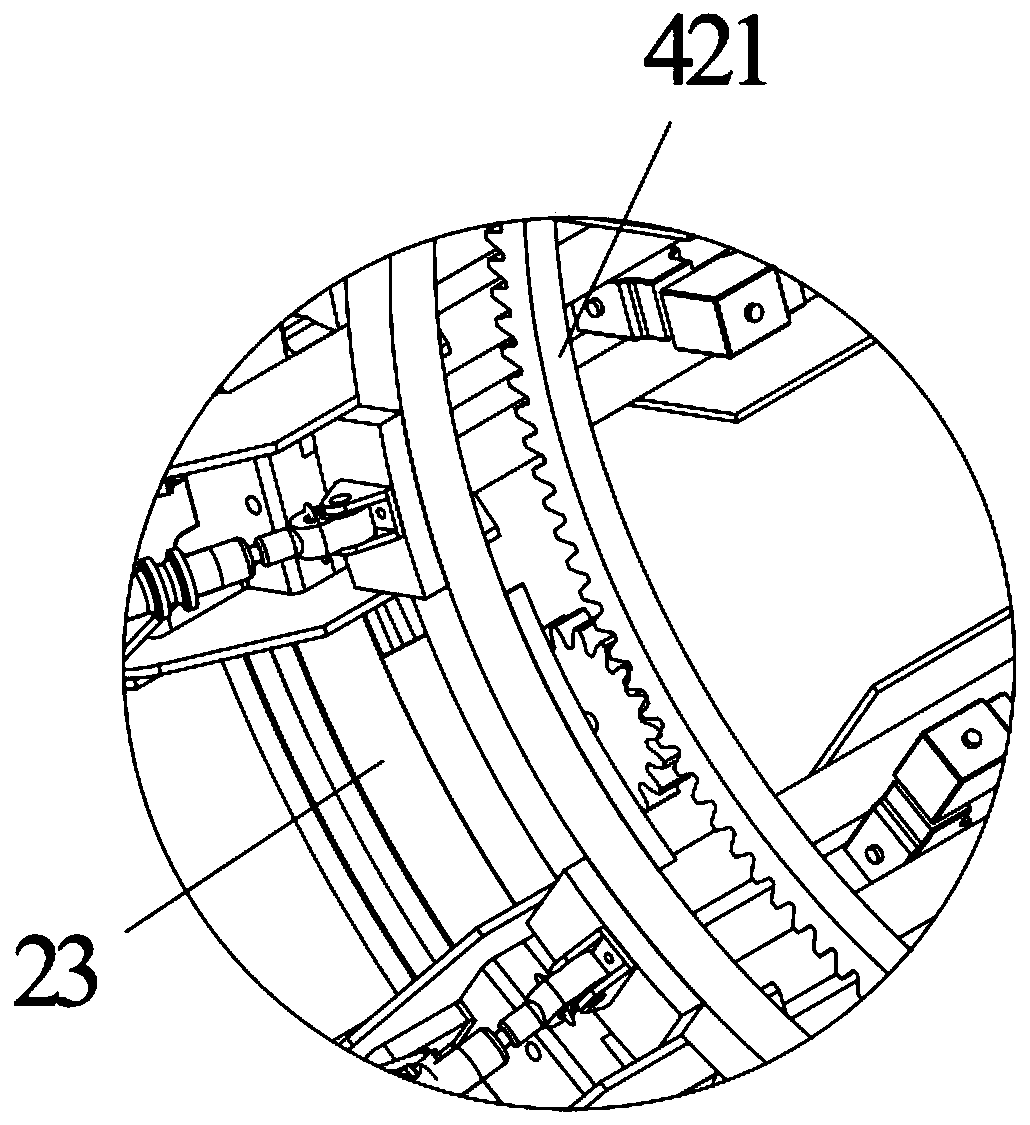

[0037] Such as Figure 1~6 As shown, a speed-controllable unpowered pipeline inspection robot includes a housing 1 and a first rotating device 2, a second rotating device 3 and a driving device 4 arranged inside the housing 1, the first rotating device 2 and the second rotating device The two rotating devices 3 are respectively arranged at both ends of the housing 1, the first rotating device 2 is meshed with the driving device 4, and the driving device 4 drives the first rotating device 2 to make the housing 1 rotate axially, the first rotating device 2 and the At least one set of wheel module 5 is arranged between the second rotating device 3 , and the wheel module 5 adjusts the moving speed of the robot by setting the first electromagnetic damping motor 511 . In the solution of the present invention, the robot relies on the force of the fluid in the pipeline to move forward in the pipeline. By setting the first electromagnetic damping motor 511 on the wheel set module 5, ac...

Embodiment 2

[0047] Such as Figure 7-8 As shown, the difference from Embodiment 1 is that universal joints 7 are respectively provided between the two ends of the main shaft body 41 and the shaft support 11 in this embodiment, through which two or more The pipeline detection robot is connected end to end, thereby providing more detection functions and endurance functions, making the invention suitable for complex pipeline detection, and greatly improving the detection ability and adaptability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com