Lubricating grease filling device

A filling device and grease technology, which is applied in the direction of manual lubricant supply, engine lubrication, engine components, etc., can solve problems such as continuous filling of grease, improve work efficiency and lubrication effect, and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

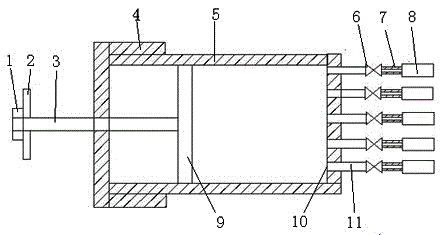

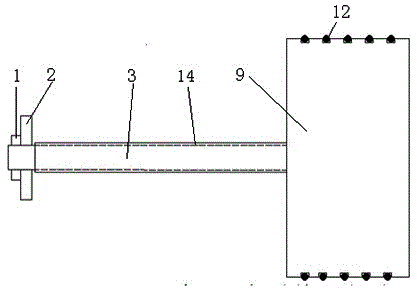

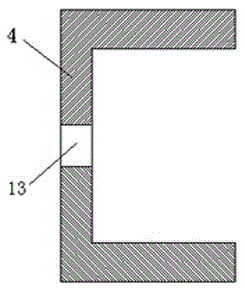

[0017] Grease filling device of the present invention such as figure 1 shown. Comprising an oil cylinder 5, a leading screw 3 and a piston 9, the piston is located in the oil cylinder. One end of the oil cylinder is provided with a gland 4, and the gland and the oil cylinder are connected by threads. Such as figure 2 , image 3 Shown, gland is provided with threaded hole 13, and leading screw is provided with external thread 14, and leading screw passes threaded hole and is connected with piston, and the other end of leading screw is provided with handle 2, and handle is fixed with nut. Such as Figure 4 As shown, the bottom of the oil cylinder is provided with five oil outlets 10, and the grease filling device is provided with a connecting pipe 11, a valve 6, a flexible pipe 7 and a connector, and the oil outlet is connected with the connector through the connecting pipe, valve and flexible pipe in turn. The piston 5 is provided with 5 sealing rubber rings 12 .

[0018...

Embodiment 2

[0020] Another embodiment of the present invention is as Figure 5 As shown, the grease filling device is provided with a motor 15 and a controller 16 . The motor is connected with the lead screw 3 through the gear mechanism 17, and the controller is connected with the motor in communication. The motor drives the lead screw to rotate through the gear mechanism, drives the piston to compress the lubricating grease in the oil cylinder, makes the lubricating grease generate pressure, and fills each lubricating part through 6 oil outlets 10 and the control valve. The controller controls the motor speed, adjusts the travel speed of the piston, and automatically controls the amount and speed of grease filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com